A cyclic short joint capable of repeated opening and closing

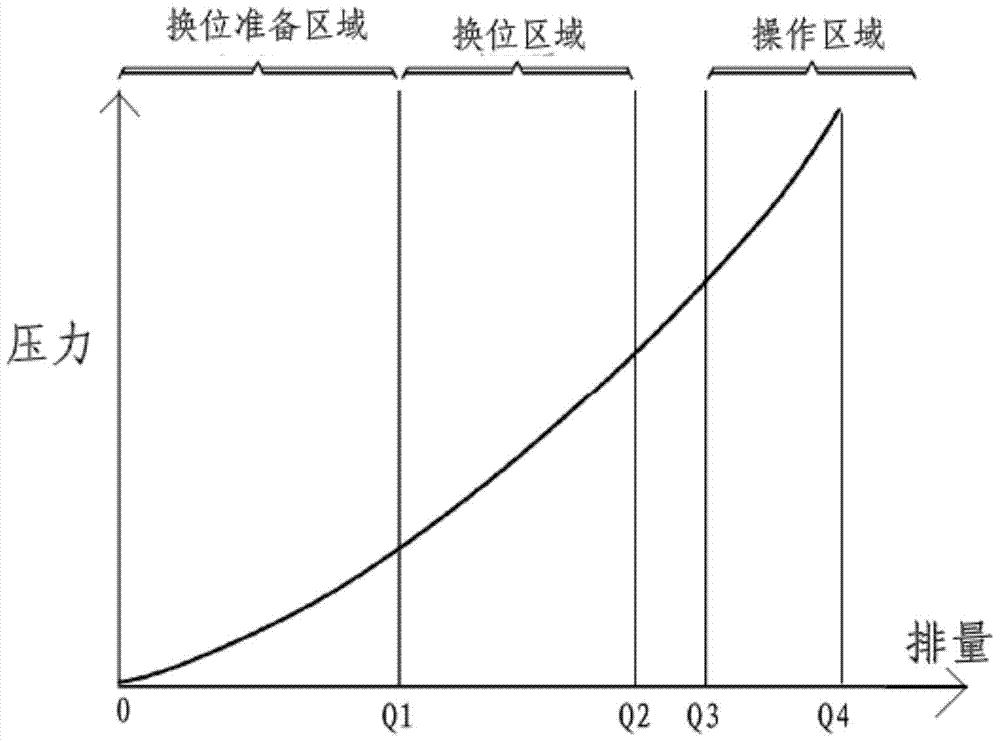

A technology of pup joints and shells, which is applied in wellbore/well components, earthwork drilling, and flushing wellbore, etc. It can solve problems affecting work efficiency, etc., and achieve fast opening and closing speed, large displacement, and well inclination angle small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

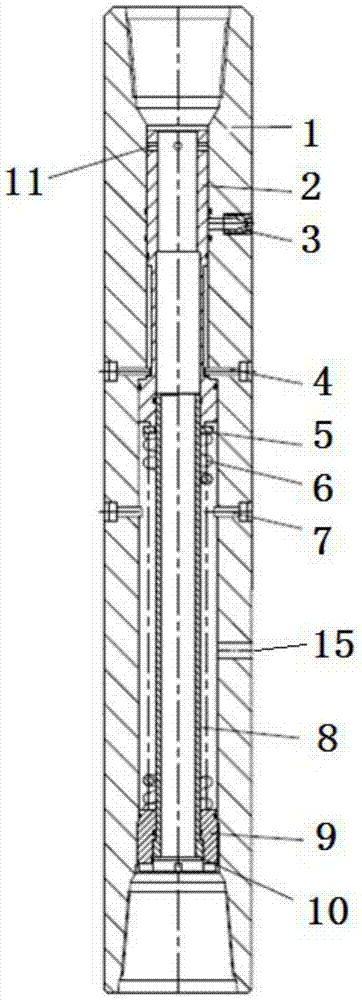

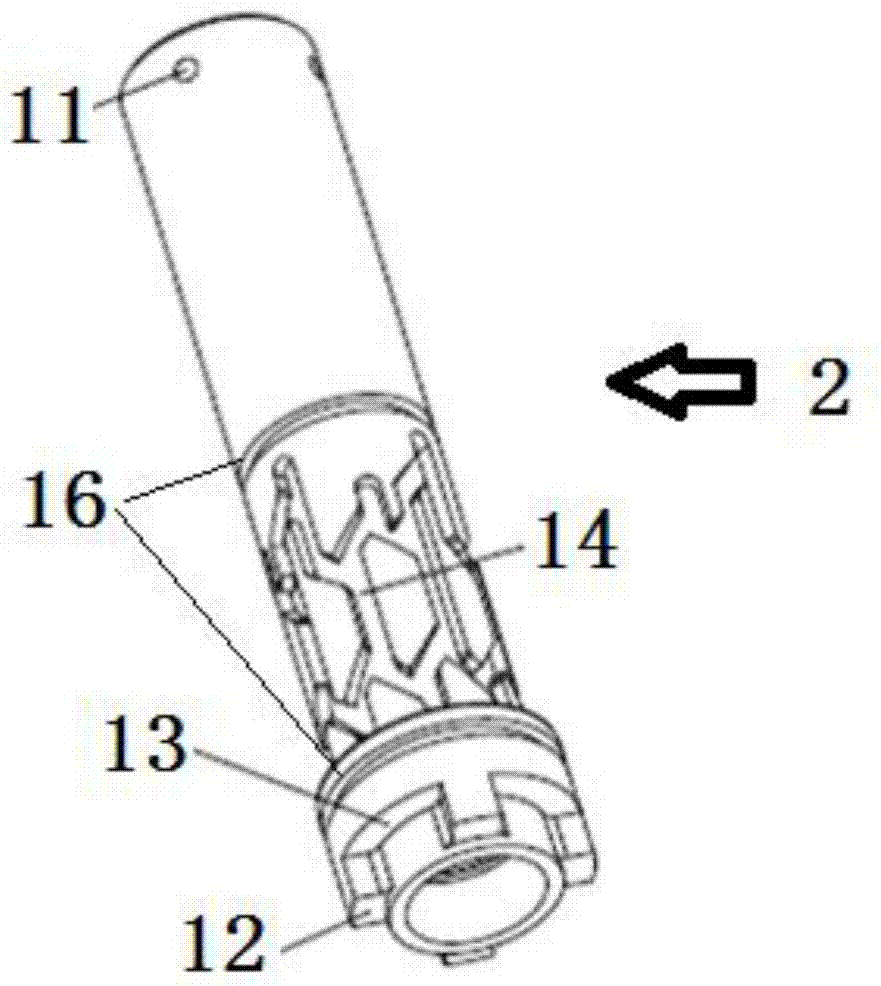

[0019] refer to figure 1 , figure 2 , the structure of the device of the present invention is that the casing 1 has a through hole along the axis line, the through hole includes a fine hole section and a thick hole section, and a nozzle 3 is installed radially on the pipe wall of the thin hole section of the casing 1, and a nozzle 3 is installed on the casing 1 1. A breathing hole 15 is radially installed on the pipe wall of the coarse hole section, and a transposition piston 2 is set in the through hole of the casing 1;

[0020] The transposition piston 2 has a transparent axial center hole, the lower end of the transposition piston 2 is provided with a step surface 13, and the lower end surface of the step surface 13 is provided with a plurality of protrusions 12 along the circumference, and the circumferential surface on the upper side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com