A warp beam cloth package yarn tester

A tester and beam cloth technology, applied in the field of laboratory testing equipment, can solve problems such as temperature instability, product quality instability, and unsuitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

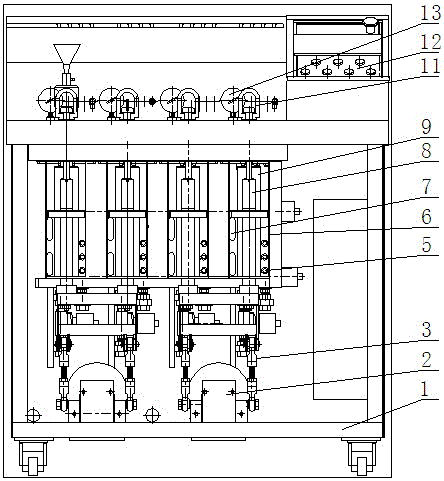

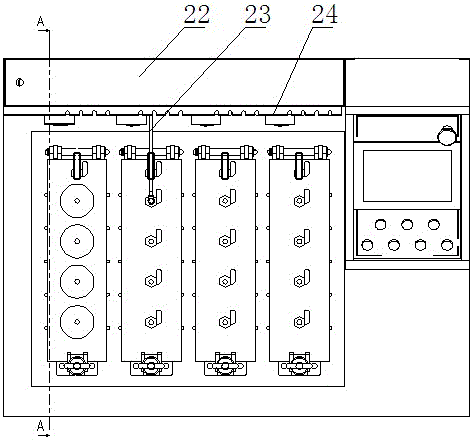

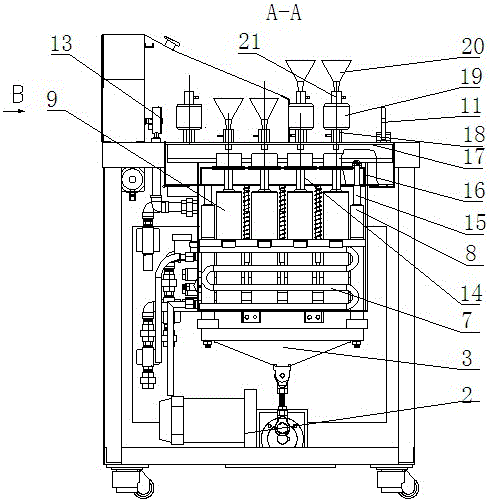

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

[0018] With reference to the accompanying drawings, a warp beam cloth package yarn tester includes a fuselage 1, a dyeing cup 9, a heating rod 5, a cooling pipe 7, and a console 12, and is characterized in that: the grooves on the fuselage 1 are arranged side by side A plurality of sealed dyeing tanks 6 are provided, and several dyeing cups 9 are arranged in the sealed dyeing tank, sealing ring fixing sleeves 8 are welded on the front and rear sides of the bottom of the sealing type dyeing tank 6, and guide posts are arranged in the sealing ring fixing sleeves 8 15. The lower end of the guide post 15 is connected to the transmission device 3, and the upper end is connected to the cloth creel fixing plate 16; there are several check ball valves A18 arranged on the top of the sealed dyeing tank 6 dyeing tank cover 17, and the top of the check ball valve A18 is in order from b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com