Oil well response stage dividing and distinguishing method under carbon dioxide miscible displacement condition

A technology of carbon dioxide and discrimination method, which is applied in the field of oil reservoir dynamic analysis and research, can solve the problems of strong subjectivity, unscientificity and blindness of oil well production characteristics, and achieve the effect of emphasizing objectivity, enhancing scientificity and overcoming subjectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

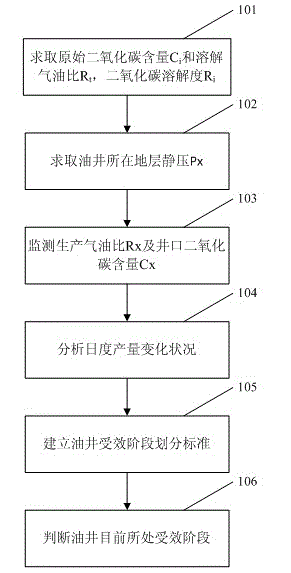

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

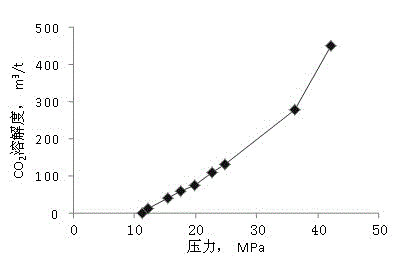

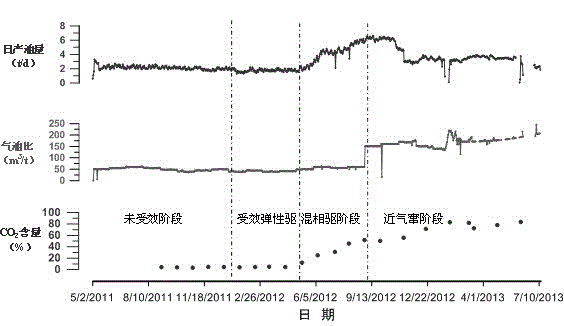

[0027] Laboratory tests show that the solubility of carbon dioxide in crude oil increases with the increase of pressure, at a certain pressure P x The solubility of carbon dioxide in crude oil is R x . Under theoretical conditions, when the reservoir pressure remains at a certain level (higher than the reservoir saturation pressure), the production gas-oil ratio and carbon dioxide content of the oil well are constant: before the front of the carbon dioxide miscible zone breaks through the bottom of the well, the carbon dioxide content at the wellhead is equal to that of the original formation Carbon dioxide content in C i , the production gas-oil ratio is equal to the original dissolved gas-oil ratio R t , after the gas flooding front breaks t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com