Axial turbine

An axial-flow turbine and turbine technology, which is applied to gas turbine devices, mechanical equipment, engine components, etc., can solve problems such as promoting mixing loss, undisclosed relationship between turbine operating states, and inability to give full play to the steering effect of guide plates, etc. The effect of mixing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

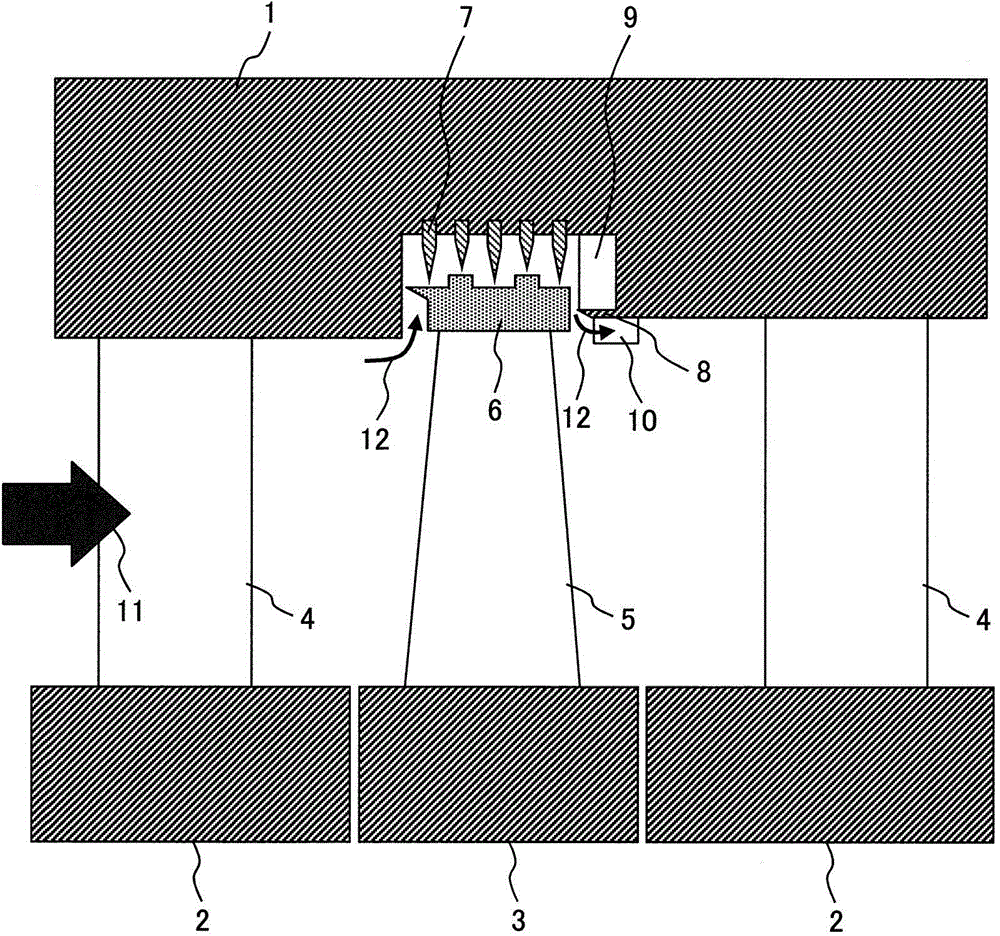

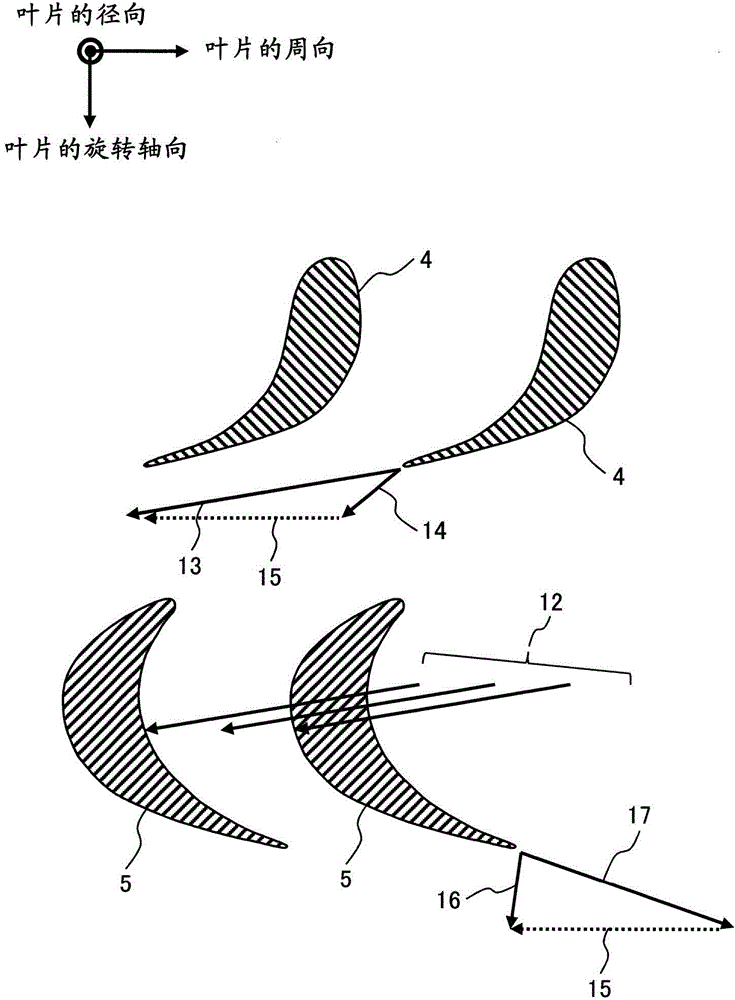

[0030] figure 1 as well as figure 2 The stage structure of the steam turbine according to Embodiment 1 of the present invention is shown. The turbine stage of the steam turbine of the present embodiment includes: a turbine rotor 3 rotatably supported; a turbine rotor blade 5 fixed to the turbine rotor 3; a shroud 6 provided at the front end of the turbine rotor blade 5; Diaphragm outer ring 1 opposite with a gap; radial sealing tab 7 , which is in the gap between shroud 6 and diaphragm outer ring 1 so as to protrude from diaphragm outer ring 1 in the radial direction of turbine rotor 3 The axial sealing fin 8 is set in the gap between the shroud 6 and the outer ring 1 of the diaphragm in a manner protruding from the outer ring 1 of the diaphragm along the rotational axis of the turbine rotor 3; a plurality of ribs 9, It is arranged in the gap between the shroud 6 and the diaphragm outer ring 1 in such a way that it is clamped by the diaphragm outer ring 1 and the axial seal...

Embodiment 2

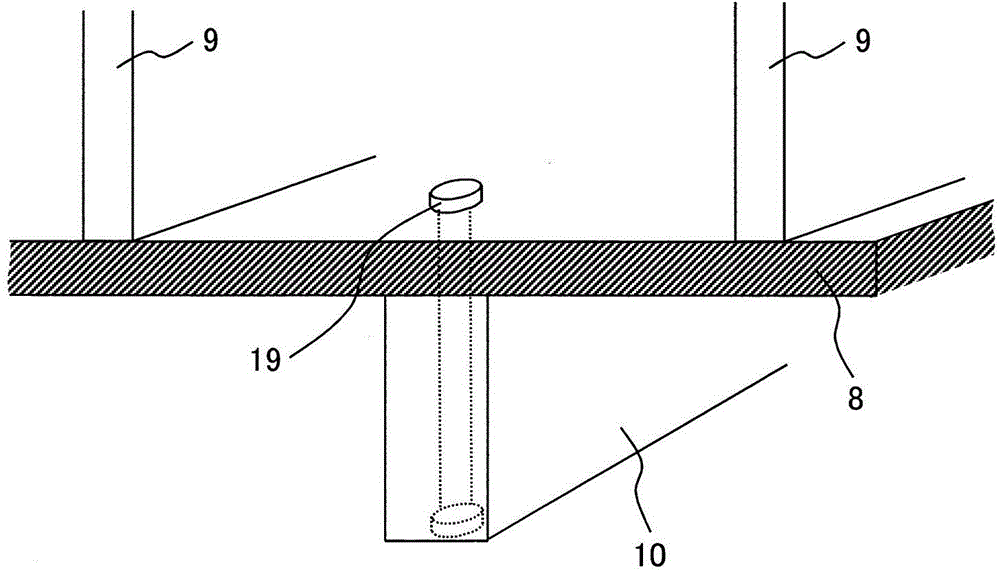

[0049] Figure 10 as well as Figure 11 The stage structure of the steam turbine according to Example 2 of the present invention is shown. in addition, Figure 12 express Figure 11 The top view of the guide plate 10. The turbine stage of the steam turbine of the present embodiment has: a turbine rotor 3 rotatably supported; a turbine rotor blade 5 fixed to the turbine rotor 3; a shroud 6 provided at the front end of the turbine rotor blade 5; Diaphragm outer ring 1 opposite with a gap; radial sealing tab 7 , which is in the gap between shroud 6 and diaphragm outer ring 1 so as to protrude from diaphragm outer ring 1 in the radial direction of turbine rotor 3 The axial sealing fin 8 is set in the gap between the shroud 6 and the outer ring 1 of the diaphragm in a manner protruding from the outer ring 1 of the diaphragm along the rotational axis of the turbine rotor 3; a plurality of ribs 9, It is set in the gap between the shroud 6 and the outer ring of the diaphragm 1 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com