Structure improved cold shield baffle of cryopump

A technology of structural improvement and cryogenic pumps, which is applied to pumps, pump components, variable capacity pump components, etc., can solve problems such as falling off, heavy workload, and long time-consuming baffle assembly, so as to achieve firm fixation, improve production efficiency, Easy to assemble and fix the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

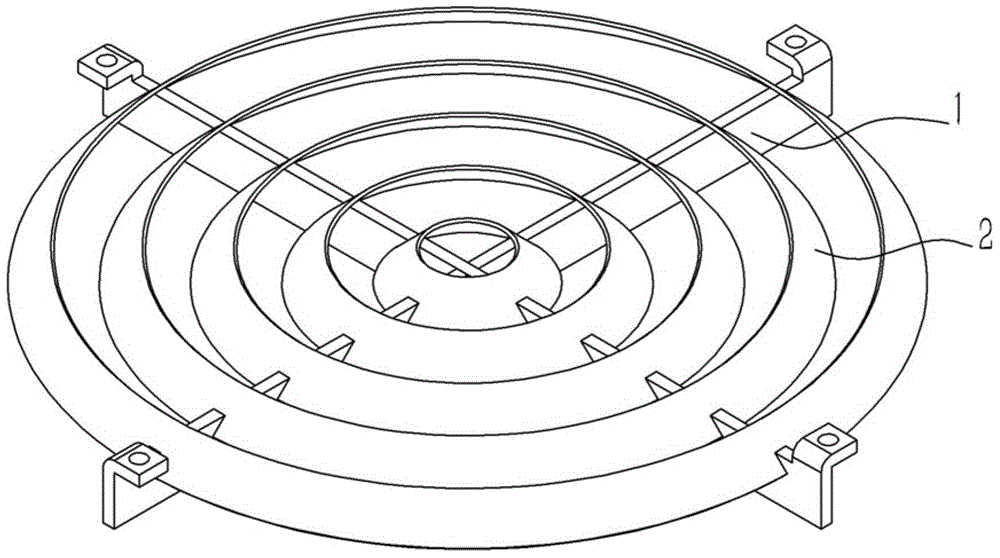

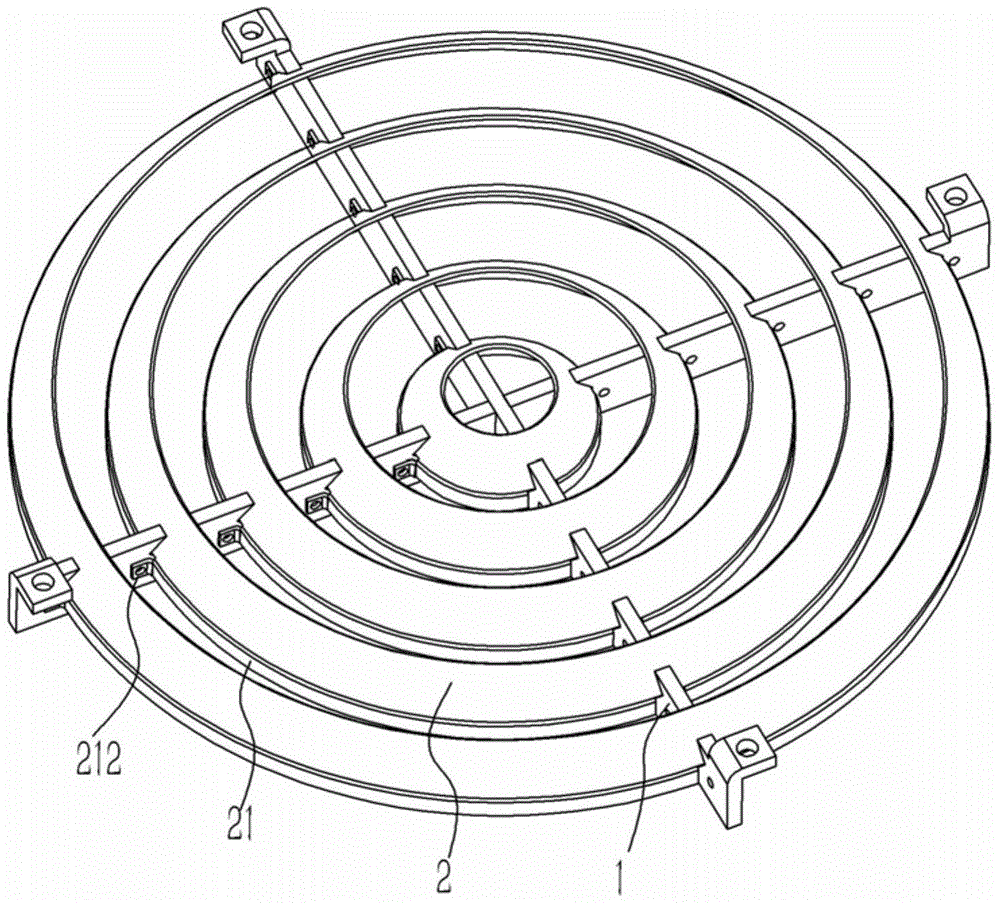

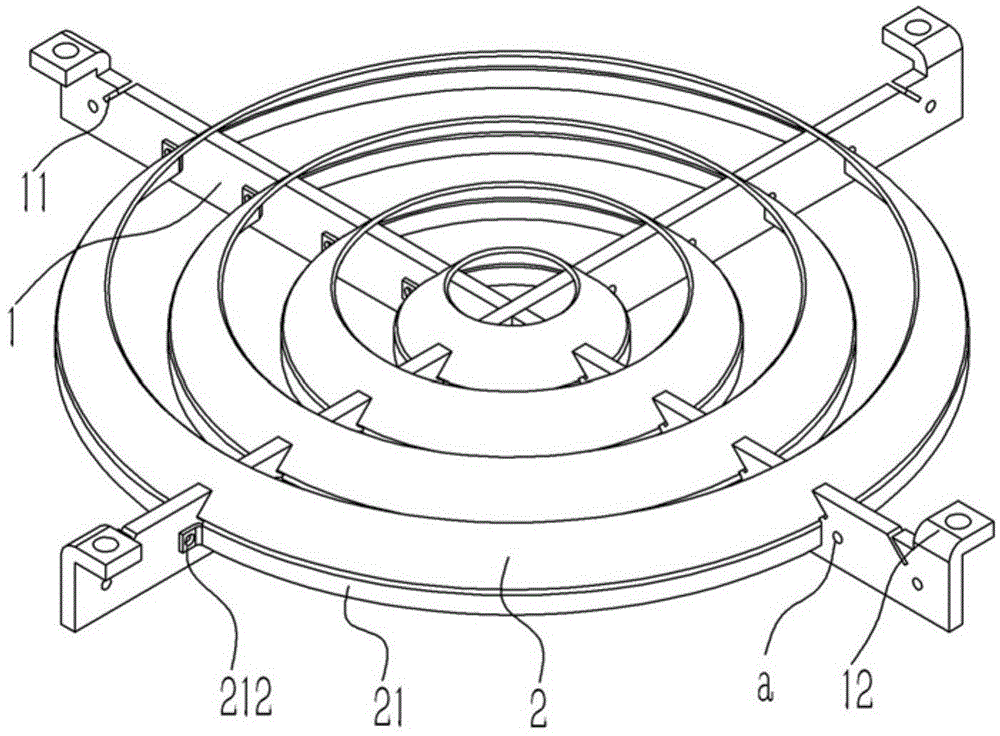

[0016] Example: see Figures 2 to 4 As shown, a cold barrier plate with improved structure on a cryopump includes a cross-shaped fixing bracket 1 and a tapered retaining ring 2. Several inclined slots 11 are formed on the fixing bracket 1, and the retaining ring 2 is inserted into the fixing bracket. In the slot 11 of 1, a vertical ring body 21 is extended and formed on the lower side of the retaining ring 2, and several notches 211 are respectively formed on the upper side of the ring body 21, and folds are formed on the sides of the notches 211 of the ring body 21. The edge 212 and the folded edge 212 lean against the side wall of the fixing bracket 1 of the retaining ring 2 and are riveted and fixed on the fixing bracket 1 by rivets.

[0017] The width of the notch 211 on the ring body 21 is greater than the thickness of each support side on the fixed bracket 1 , and the notch 211 is inserted and sleeved on the fixed bracket 1 .

[0018] Corresponding rivet holes a are for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com