High-accuracy detachable worm gear drive mechanism

A technology of worm gear and transmission mechanism, which is applied in the direction of gear transmission, transmission, transmission parts, etc., which can solve the problems of large influence of return stroke error, reduction of instrument measurement accuracy, and high cost of precision machining, so as to achieve high transmission accuracy and easy operation. Convenience, Freedom and Flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

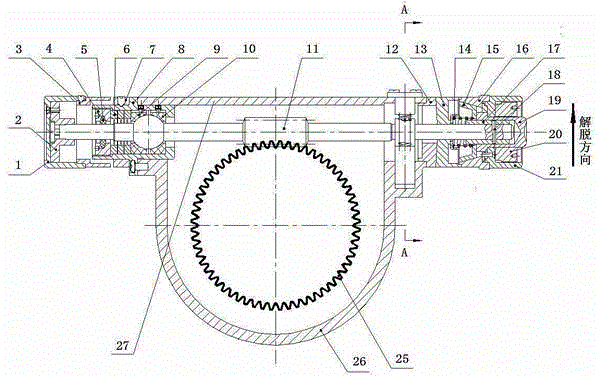

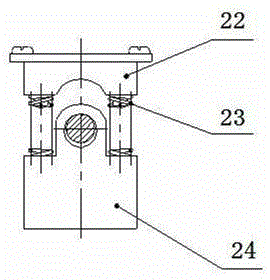

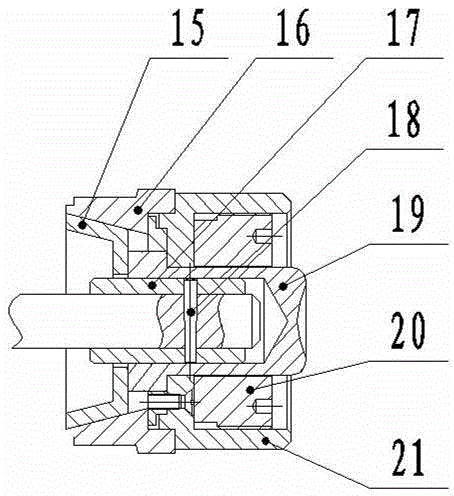

[0018] See Figure 1-5 , the specific structure is as follows: the worm wheel 25 is connected to the base (known structure, not shown in the figure), and the worm 11 is assembled in the housing 26 to mesh with the worm wheel 25; Bearing one 10 and bearing two 9 with inner spherical surfaces are fixedly assembled inside, and one side of the worm screw 11 is designed with a spherical part, which is matched with the inner spherical surfaces of bearing one 10 and bearing two 9; Partially turned. In the bearing seat 8, the spring barrel 6 is assembled by compressing the pressure ring 4 with external thread, and the felt sealing ring 5 is assembled in the pressure ring 4; see Figure 5 , The spring cylinder 6 is provided with multiple radial notches 6-1 on the metal cylinder body, and the circumferential positions of adjacent notches 6-1 are staggered by 90o, so that it has certain axial elasticity. The assembly index 7 is fixed outside the bearing seat 8; the bracket 2 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com