Coil with air core of forcipated duplex winding based on printed circuit board

A printed circuit board, double-winding technology, applied in circuits, including printed electrical components, inductors, etc., can solve the problems of air-core coils such as large volume, uncertain direction, and reduced measurement accuracy, and achieve strong resistance to external magnetic field interference. , Reduce the occupied space, the effect of uniform magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in conjunction with the accompanying drawings.

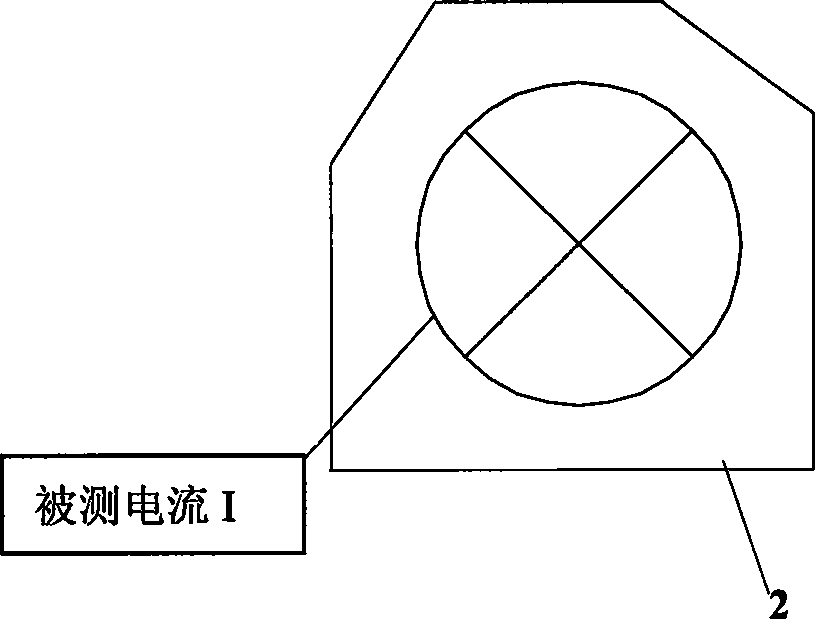

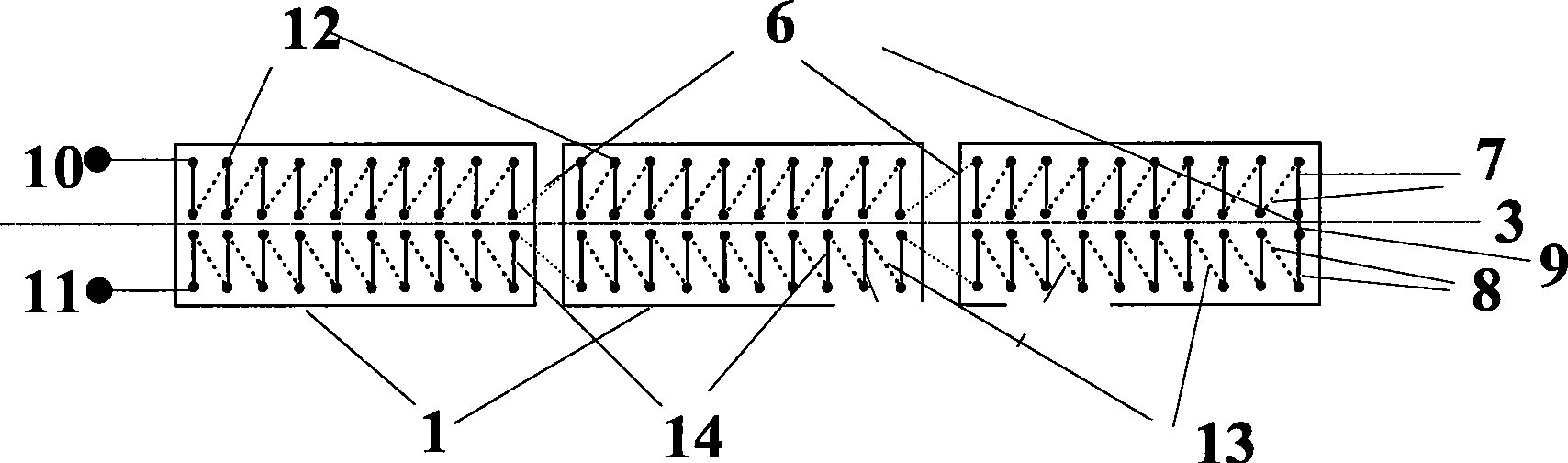

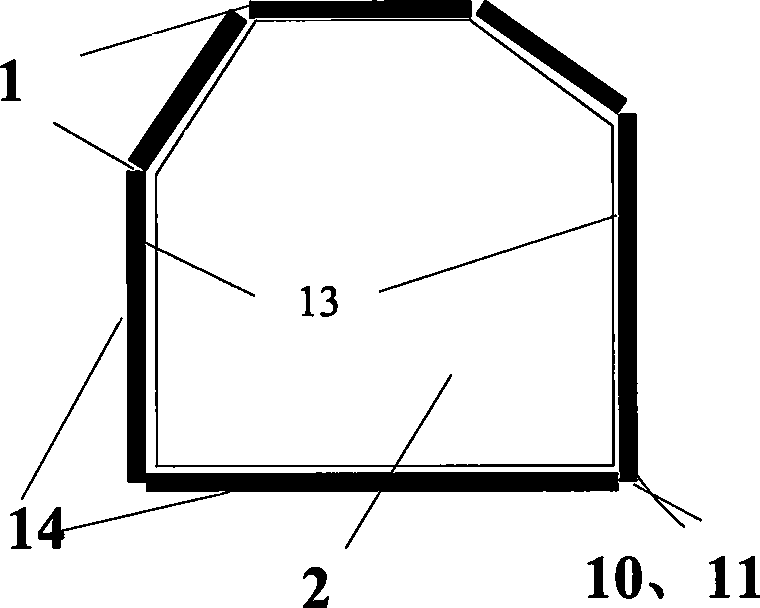

[0029]The air-core coil of the present invention is composed of several printed circuit boards connected end to end. These printed circuit boards have the same thickness and width. The length of each printed circuit board corresponds to a certain side length of the wire shape. The air-core coil of the invention It can realize flexible "fit-to-fit design and installation" without cutting off the tested wire. Each printed circuit board in the coil has two parallel windings, and the two sets of windings are symmetrical along the center line of the circuit board.

[0030] According to specific measurement requirements, the output of the air-core coil can be connected to an integrator or not. Measure the magnitude of the measured current by measuring the output voltage of the coil or the output voltage of the integrator.

[0031] The present invention has no special requirements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com