Displacement measuring apparatus for concrete temperature-pressure tester and application thereof

A concrete temperature and stress test technology, applied in the field of measurement, can solve the problems of not considering the influence of measurement accuracy, unable to study high-strength concrete, and greater than 1.5%, to eliminate measurement errors, strong anti-interference ability, and eliminate errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

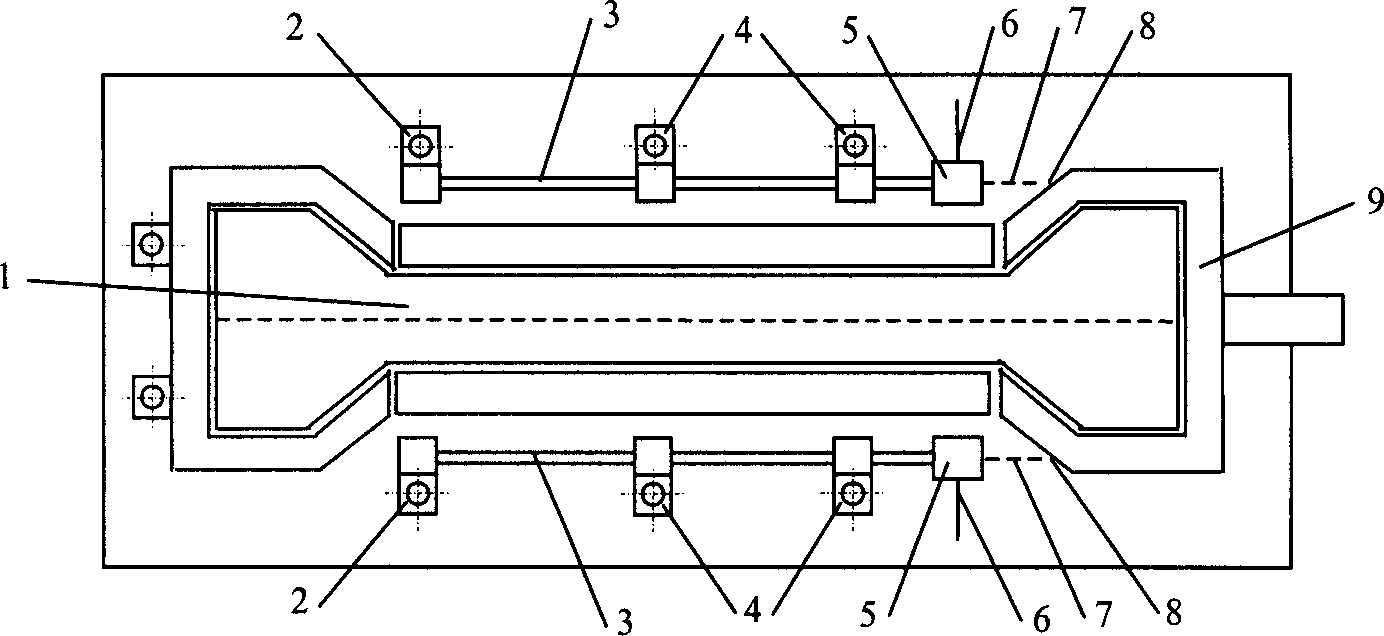

[0030] Example 1: Non-contact measuring device using laser triangulation

[0031] Such as Figure 4 As shown: the beam of the laser emitter 12 is focused by the focusing lens 13 and hits a certain point on the movable end 9 of the concrete specimen 1 , and part of the scattered beam passes through the imaging lens 14 and hits the charge-coupled device 15 . When the movable end 9 moves the displacement x in the beam direction, the corresponding displacement y of the CCD 15 can be calculated. Such as Figure 4 The line AD is perpendicular to the line BO, the area of the triangle ABO is:

[0032] S=AD·BO=AB·AO·sin(π-φ) (1)

[0033] And the law of cosines:

[0034] BO 2 =AB 2 +AO 2 +2·AB·AO·cosφ (2)

[0035] Organized:

[0036] AD = AB · sin φ · 1 ( AB ...

Embodiment approach 2

[0044] Embodiment 2: Non-contact measuring device adopts interferometry

[0045] Such as Figure 5As shown: the laser beam emitted by the laser emitter 17 passes through the polarizer 18 and the 1 / 4 wave plate 19 and reaches the beam splitter 22 and then is divided into two beams, one is a reflected beam and the other is a transmitted beam. The reflected light beam is reflected back to the beam splitter 22 after passing through the front lens 20 and the fixed reflector 21 . The transmitted beam reaches the movable end 9 of the concrete specimen 1 through the front lens 23, and then reflects back to the beam splitter 22. The reflected beam and the transmitted beam interfere at the beam splitter 22, pass through the focusing lens 24, and then form a focus on the charge-coupled device 25 .

[0046] Since the optical path length of the reflected light beam remains unchanged, the optical path length of the transmitted light beam changes with the movement of the movable end 9 . T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com