A pretreatment method for waste incineration in alpine underdeveloped areas

An underdeveloped technology of waste incineration, applied in the field of waste incineration pretreatment, can solve the problems of waste combustion calorific value reduction, combustion calorific value drop, grate collision, etc., to achieve economic benefits, increase incineration calorific value, and reduce equipment failures. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

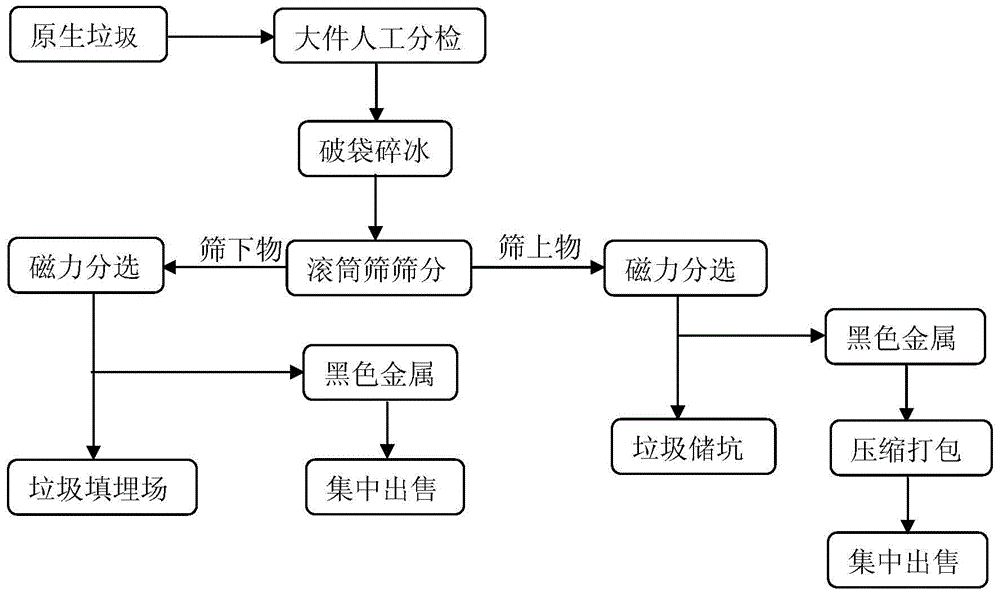

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0017] 1. Garbage is transported by the conveyor belt to the large-size sorting station for manual sorting of large pieces;

[0018] 2. The sorted garbage is fed from the conveyor belt to the bag-breaking ice crusher, which tears the garbage bags and crushes the ice cubes and ice lumps in the domestic garbage;

[0019] 3. The garbage is evenly supplied to the drum screen by the conveyor belt, and the dregs in the garbage become the undersize, and other components become the oversize;

[0020] 4. After magnetic separation, the underscreen material containing a large amount of slag is transported out by the conveyor belt and concentrated, and then transported to the landfill for landfill;

[0021] 5. After reaching a certain amount of ferrous metals separated by magnetic force in the underscreen, they will be sold together;

[0022] 6. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com