A method for on-line detection of oil tank capacity by fiber grating

A fiber grating and fiber grating demodulation technology, applied in the direction of volume measuring instruments/methods, measuring capacity, measuring devices, etc., can solve the problems of inapplicability of electrical sensors, achieve high accuracy and reduce the number of channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

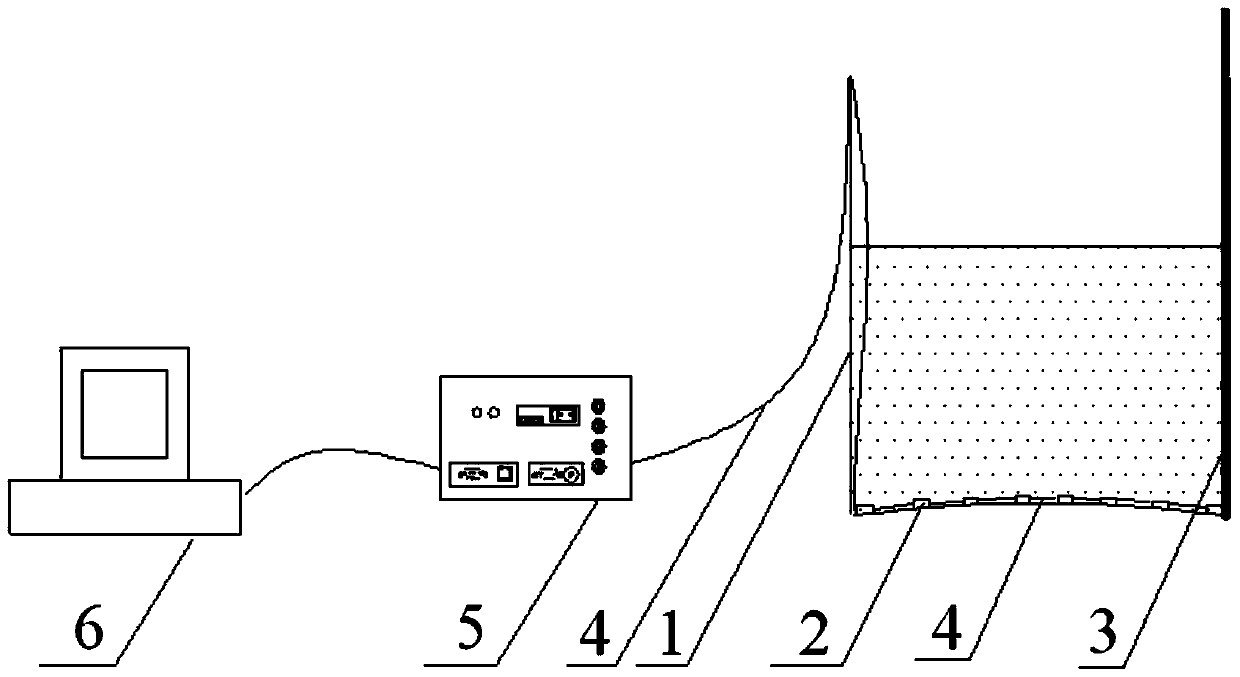

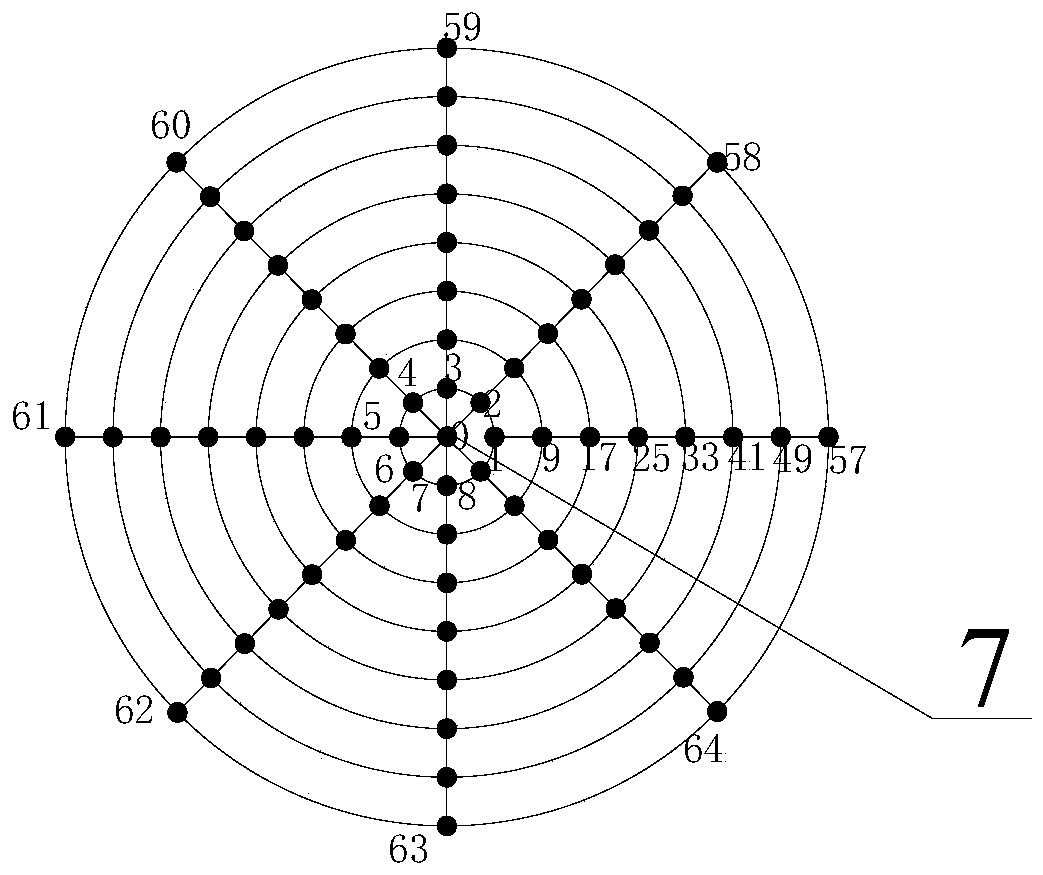

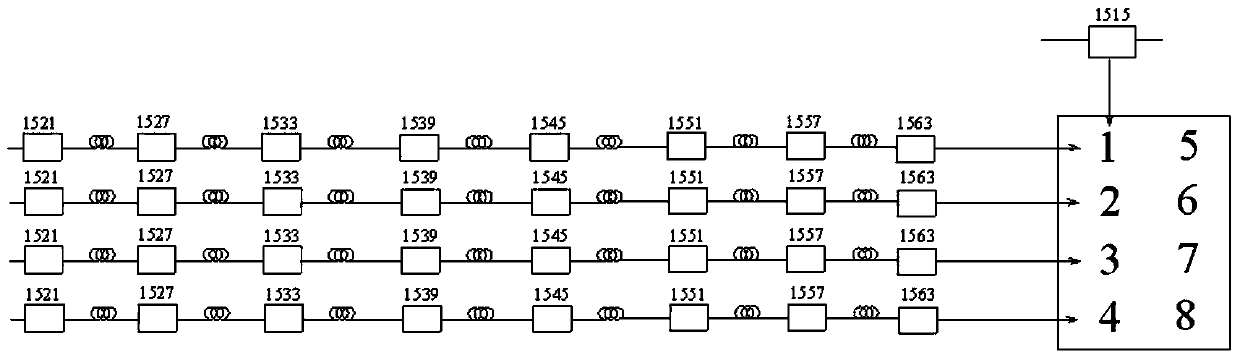

[0022] Such as figure 1 with figure 2 As shown, the liquid capacity online detection device in the oil tank of the present invention includes an oil tank 1; an optical fiber grating liquid level sensor 2; a dipstick 3; an optical fiber 4; an optical fiber grating demodulator 5; a PC 6; Among them, the optical fiber grating liquid level sensor 2 and the optical fiber grating temperature sensor 7 are fixed on the bottom surface of the oil tank 1 by welding, the sensors of the same channel are connected with the optical fiber 4, and the sensors of 8 channels are connected to the optical fiber grating across the top of the oil tank through the optical fiber 4 In the demodulator 5, the demodulator 5 is connected to the PC 6 through a network cable.

[0023] The oil tank in this embodiment is a 100,000 cubic meter oil tank with a height of 20 meters and a bottom diameter of 80 meters. The spacing between them adopts the same distribution structure to make it suitable for the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com