Arc-free matrix intelligent bridge strong control high voltage circuit breaker

A high-voltage circuit breaker and arc-free technology, which is applied to circuit breaker components, circuits, high-voltage/high-current switches, etc., can solve problems such as inability to replace mechanical switches, inability to replace power circuit breakers, and potential safety hazards caused by thermal hazards. Achieve the effect of promoting R & D and production, breaking through the serious threat of arc, and simplifying the control and protection circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

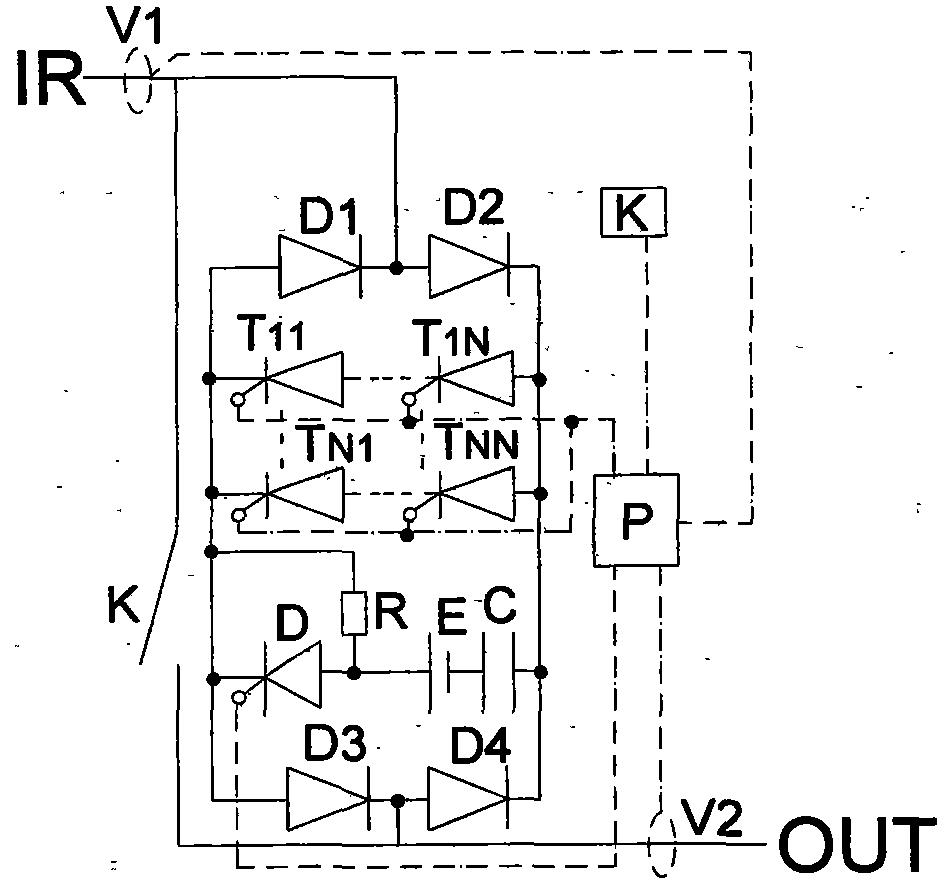

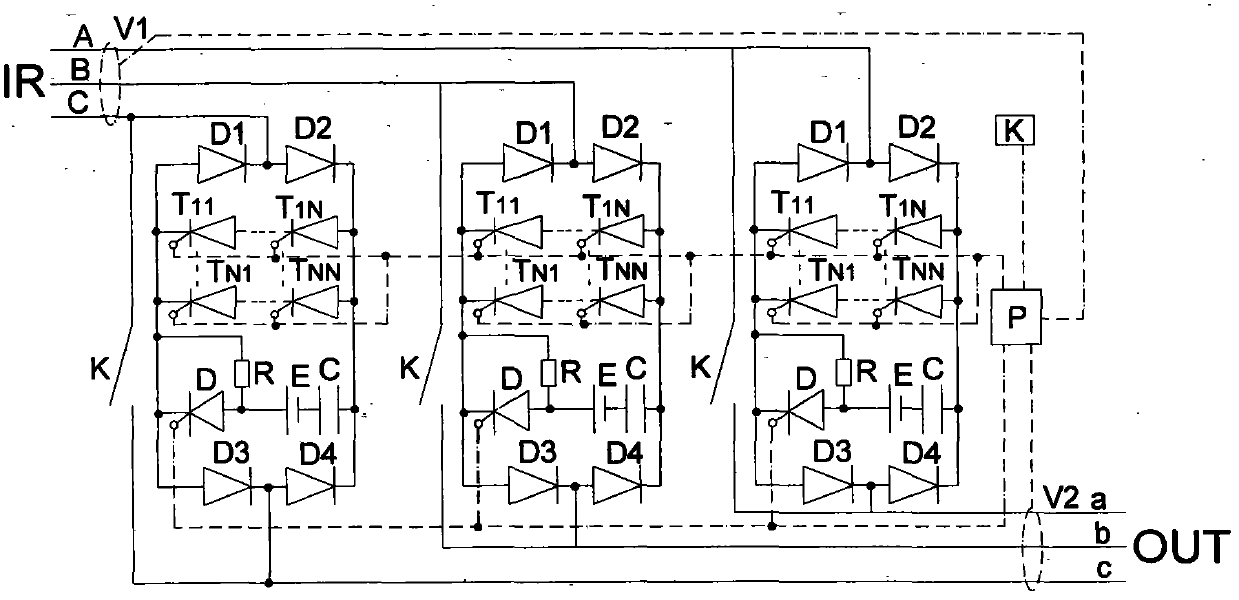

[0017] Such as figure 1 , as shown in 2, the arc-free amplified bridge high-voltage power circuit breaker is composed of a mechanical switch K, a bridge switch and its strong control circuit, a controller P, and monitoring instruments V1 and V2. After the main contacts of the bridge switch and K are connected in parallel Connected between power input (IR) and power output (OUT).

[0018] According to the connection mode and quantity of the main switching tube in the bridge switch, the non-contact channel of the arc-free intelligent bridge high voltage circuit breaker is divided into intelligent bridge type, parallel intelligent bridge type, series intelligent bridge type, matrix intelligent bridge type, There are eight forms of smart bridge strong control, parallel smart bridge strong control, series smart bridge strong control and matrix smart bridge strong control, collectively referred to as "bridge switch". This patent describes the matrix smart bridge strong control , it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com