Method of fast preparing and screening nanometer IIB semiconductor light-emitting material

A nano-luminescent material and semiconductor technology, applied in the direction of luminescent materials, chemical instruments and methods, can solve the problems of long cycle, low output, and large contingency of luminescent performance, and achieve the improvement of fluorescence intensity, reduction of test cost, and shortening of screening cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

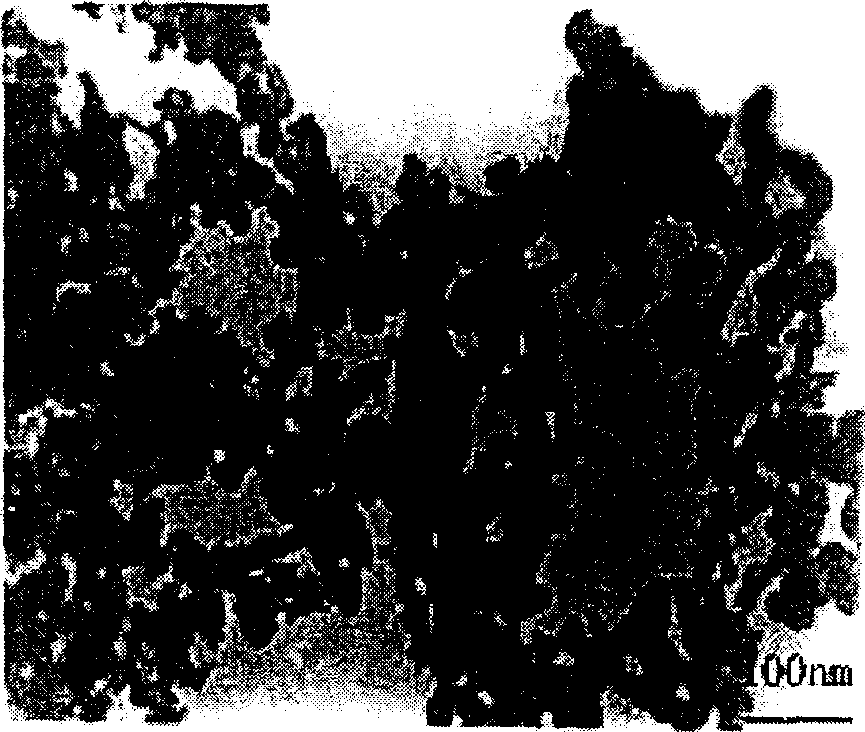

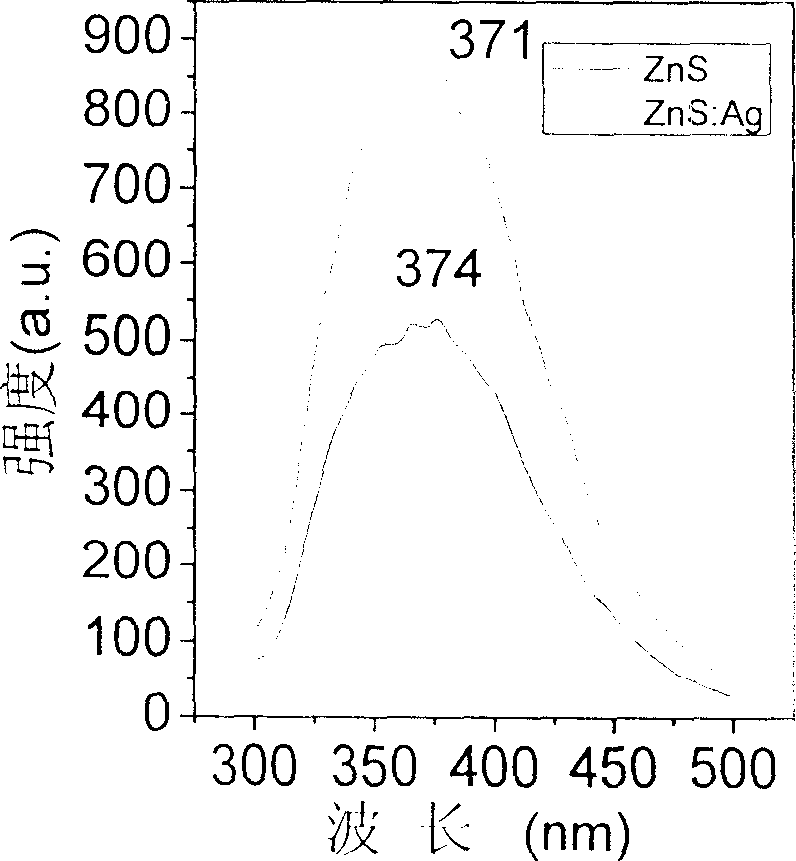

[0032] (1) As shown in Table 1, use the orthogonal design method to design 9 kinds of silver-doped zinc sulfide nano-crystallite schemes, and comprehensively consider the factors that affect the morphology and performance of the product;

[0033] No.

c(M)

n (zinc nitrate: silver nitrate)

n (zinc nitrate + silver nitrate): n (sodium sulfide)

n(SDS):n(sodium sulfide)

1

2

0.1

0.1

5∶5

5∶3

1∶1

1∶0.9

1∶48

1∶50

3

4

5

6

7

8

9

0.1

0.2

0.2

0.2

0.5

0.5

0.5

5∶1

5∶5

5∶3

5∶1

5∶5

5∶3

5∶1

1∶0.8

1∶0.9

1∶0.8

1∶1

1∶0.8

1∶1

1∶0.9

1∶52

1∶50

1∶52

1∶48

1∶52

1∶48

1∶50

[0034] (2) Prepare certain concentrations of zinc nitrate, silver nitrate, sodium sulfide and sodium dodecyl sulfate (SDS) according to the requirements of Table 1 and fill them in beakers respectively; ...

Embodiment 2

[0040] (1) As shown in Table 2, nine kinds of manganese-doped cadmium sulfide nanocrystallite schemes were designed by using the orthogonal design method, and the factors affecting the product morphology and performance were comprehensively considered;

[0041] No.

c(M)

n (cadmium nitrate: manganese nitrate)

n (cadmium nitrate + manganese nitrate): n (sodium sulfide)

n(SDS):n(sodium sulfide)

1

2

3

4

5

6

7

0.1

0.1

0.1

0.2

0.2

0.2

0.5

5∶5

5∶3

5∶1

5∶5

5∶3

5∶1

5∶5

1∶1

1∶0.9

1∶0.8

1∶0.9

1∶0.8

1∶1

1∶0.8

1∶48

1∶50

1∶52

1∶50

1∶52

1∶48

1∶52

8

9

0.5

0.5

5∶3

5∶1

1∶1

1∶0.9

1∶48

1∶50

[0042] (2) Prepare certain concentrations of soluble cadmium nitrate, manganese nitrate, sodium sulfide and sodium dodecyl sulfate (SDS) according to the requirements of Table 2 and fill t...

Embodiment 3

[0048] (1) As shown in Table 3, nine kinds of manganese-doped cadmium sulfide nanocrystallite schemes were designed by using the orthogonal design method, and the factors affecting the product morphology and performance were comprehensively considered;

[0049] No.

c(M)

n (cadmium acetate: manganese acetate)

n (cadmium acetate + manganese acetate): n (sodium sulfide)

n(SDS):n(sodium sulfide)

1

2

3

4

5

6

7

8

9

0.1

0.1

0.1

0.2

0.2

0.2

0.5

0.5

0.5

5∶5

5∶3

5∶1

5∶5

5∶3

5∶1

5∶5

5∶3

5∶1

1∶1

1∶0.9

1∶0.8

1∶0.9

1∶0.8

1∶1

1∶0.8

1∶1

1∶0.9

1∶48

1∶50

1∶52

1∶50

1∶52

1∶48

1∶52

1∶48

1∶50

[0050] (2) Prepare a certain concentration of soluble cadmium acetate, manganese acetate, sodium sulfide and sodium dodecyl sulfate (SDS) according to the requirements of Table 3 and fill them in beakers re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com