Electrode rotating conducting structure

A conductive structure and electrode technology, applied in the direction of flexible/rotatable wire connectors, circuits, electrical components, etc., can solve the problems of bulky equipment, complex conductive structure forms, and failure of activity-oriented structures, and achieve the effect of ensuring the conductive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention are described in detail below.

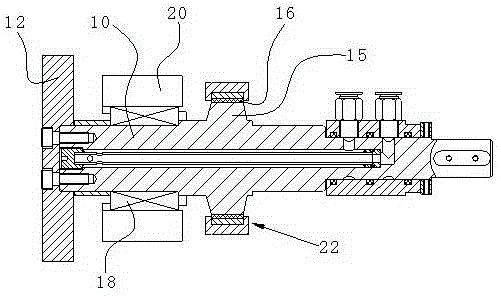

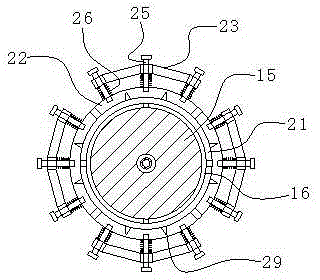

[0013] Such as figure 1 , figure 2 As shown, an electrode rotating conductive structure of the present invention includes an electrode shaft 10 with an electrode wheel 12 installed at one end, and an electrode seat 20 sleeved on the electrode shaft 10. The electrode shaft 10 is provided with a trapezoidal or rectangular section. The shaft shoulder 15, the electrode seat 20 is provided with a ring clamp, and a silver electrode tile 16 is provided between the shaft shoulder 15 and the ring clamp, and the ring clamp includes at least two arc-shaped elastic pressing pieces 22, and the elastic pressing Shrinkage gaps are preset between the sheets 22 , and gaskets 21 for pressing the electrode tiles are provided between the elastic pressing sheets 22 and the electrode tiles 16 . Since the clamping radius of the ring clamp attached to the electrode holder 20 for clamping the silver sheet (that is, the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com