Electrode rotation electric conduction structure

A conductive structure and electrode technology, applied in the direction of electrode accessories, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of bulky equipment, difficult installation and maintenance, failure of movable guide structure, etc., and achieve the effect of ensuring the conductive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention are described in detail below.

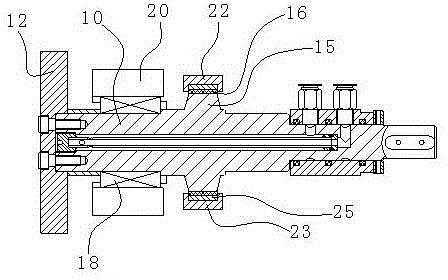

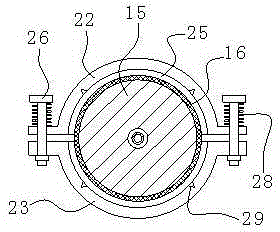

[0014] Such as figure 1 , figure 2 As shown, an electrode rotating conductive structure of the present invention includes an electrode shaft 10 with an electrode wheel 12 installed at one end, and an electrode seat 20 sleeved on the electrode shaft 10. The electrode shaft 10 is provided with a trapezoidal or rectangular section. The shaft shoulder 15, the electrode seat 20 is provided with a ring clamp, and a silver electrode tile 16 is arranged between the shaft shoulder 15 and the ring clamp, and the ring clamp includes a semi-annular upper clamp body 22 and a lower clamp body butted against each other. Body 23, the upper clamp body 22 and the lower clamp body 23 are all embracing pressing parts with variable radius, and a contraction gap is preset between the upper clamp body 22 and the lower clamp body 23, and the upper clamp body 22 and the lower clamp body 23 are in contact with the lower clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com