A multi-layer filter element

A multi-layer filter element and filter element technology, which is applied in the direction of filtration separation, gravity filter, loose filter material filter, etc., can solve the problems of increasing use cost, material waste, and increasing the service life of filter material, so as to prevent secondary No pollution, easy to use, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

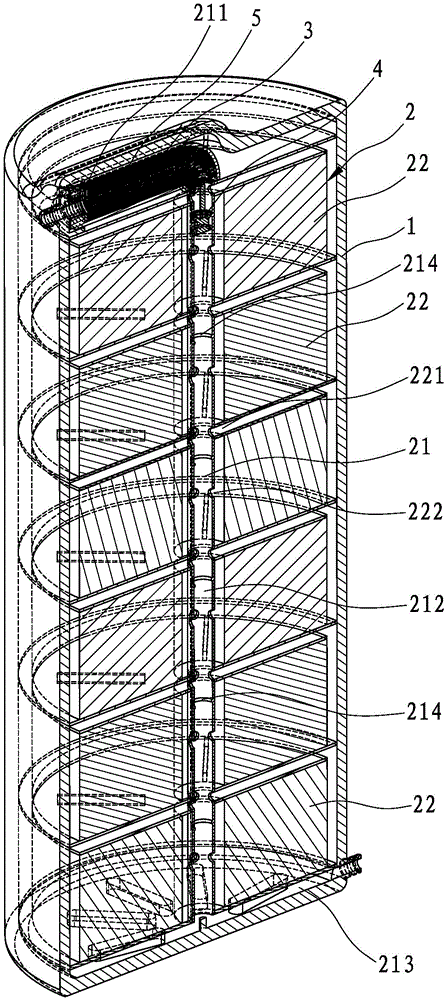

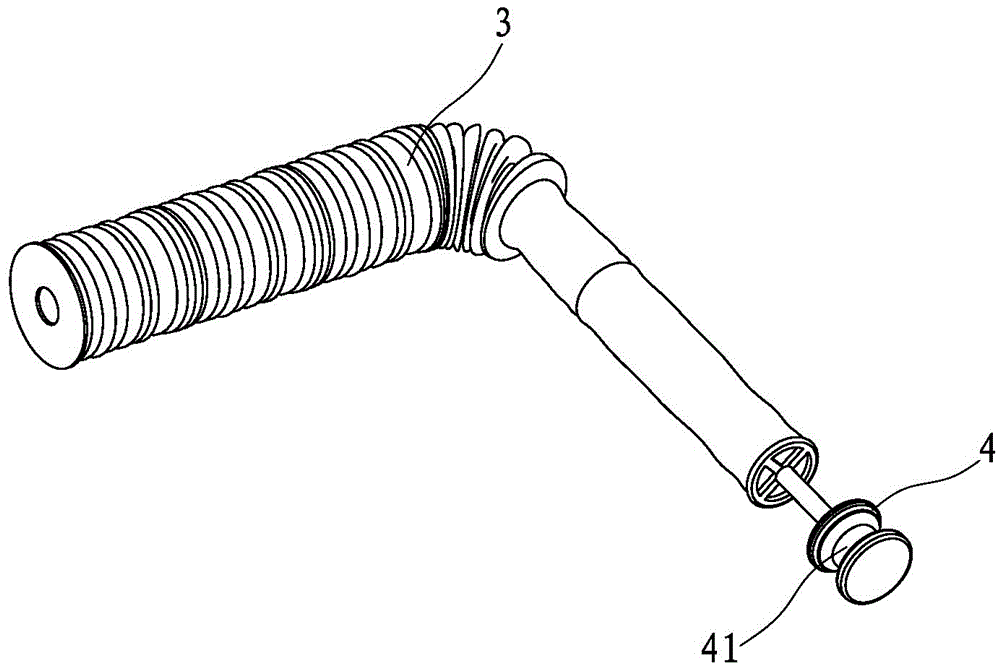

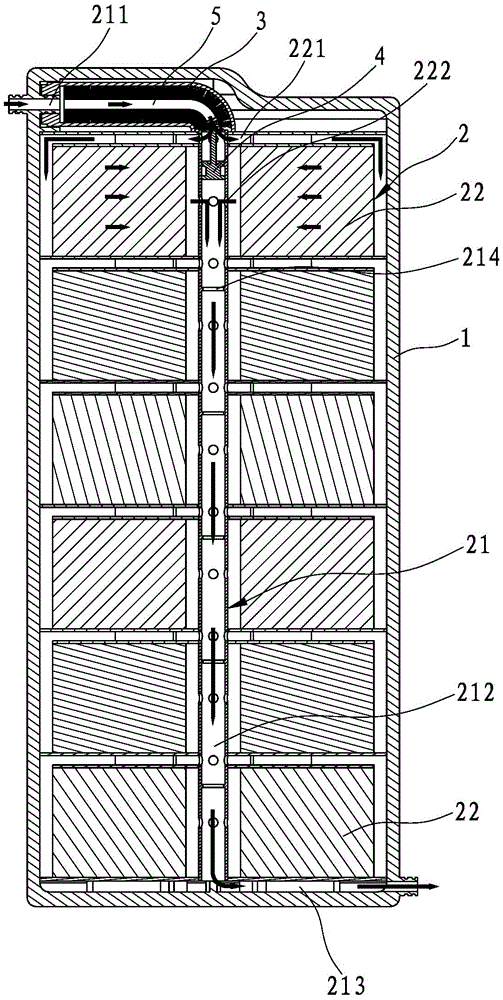

[0037] refer to Figure 1 to Figure 5 As shown, a multi-layer filter element disclosed by the present invention includes a filter element housing 1 , a filter element body 2 , a telescopic tube 3 and a piston 4 .

[0038] The filter element body 2 is installed in the filter element housing 1, and a water flow channel 21 is set in the filter element body 2, one end of the water flow channel 21 is the water inlet end, and the other end of the water flow channel 21 is the water outlet end.

[0039] The filter element main body 2 is composed of multiple independent filter element interlayers 22 , and each filter element interlayer 22 is respectively provided with a water inlet hole 221 and a water outlet hole 222 connected to the water flow channel 21 .

[0040] A waterway communicating with the water flow channel 21 is formed in the telescopic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com