A temperature-variable concentrated absorbent for capturing carbon dioxide and its application method

A carbon dioxide and absorbent technology, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, can solve problems such as increased environmental protection risks, difficult process design, and low reaction speed, and achieve total capture cost reduction and system performance. The effect of reducing consumption and reducing total investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

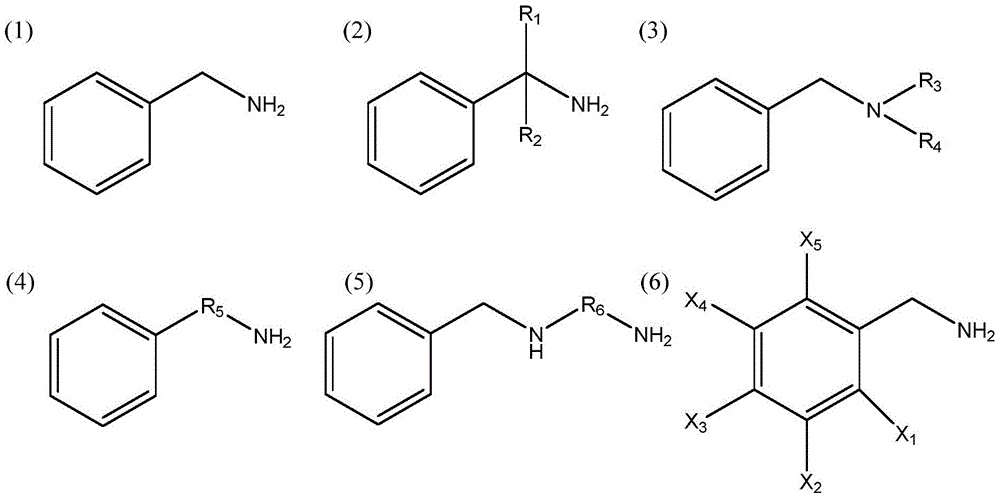

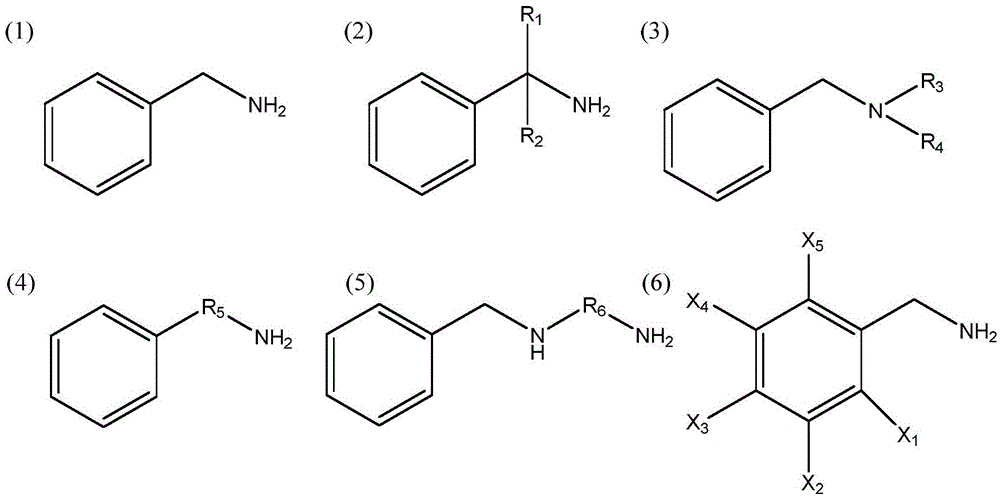

[0023] Example 1, a temperature-variable concentration absorbent for capturing carbon dioxide, each component is recorded as: variable temperature concentration amine 35%, pH regulator 5%, auxiliary agent 0.01%, water: balance, variable temperature concentration The amine is benzylamine, the pH regulator is potassium carbonate, and the auxiliary agent is an organosiloxane defoamer.

[0024] The method of use is as follows: the absorbent solution in the absorption tower reacts with the gas containing carbon dioxide to form a rich liquid, the absorption temperature: 40-50°C, the absorption pressure: 1Mpa, the ratio of the amount of absorbed carbon dioxide to the amount of benzylamine When the primary rich liquid leaves the absorption tower, it is cooled down to 25°C, and then the solids rich in carbon dioxide products are collected by the solid-liquid separator, and the separated liquid is sent back to the lean liquid storage tank, and the concentrated solids are produced by the ...

Embodiment 2

[0025] Example 2, a temperature-variable concentrated absorbent for capturing carbon dioxide, each component is recorded as: 30% variable-temperature concentrated amine, 5% pH regulator, water: balance, variable-temperature concentrated amine is benzylamine, The pH regulator is potassium hydroxide.

[0026] The method of use is: the absorbent solution in the absorption tower reacts with the gas containing carbon dioxide to form a rich liquid, the absorption temperature: 40-50°C, the absorption pressure: 1-1.1bar, the amount of absorbed carbon dioxide and the amount of benzylamine The amount ratio is more than 0.35. After the primary rich liquid leaves the absorption tower, it is cooled down to 30°C, and then the solids rich in carbon dioxide products are collected by the solid-liquid separator, and the separated liquid is sent back to the lean liquid storage tank, and the concentrated solids are collected by the The hot lean liquid produced by the regeneration tower is heated ...

Embodiment 3

[0027] Example 3, a temperature-variable concentrated absorbent for capturing carbon dioxide, each component is recorded as: variable temperature concentrated amine 25%, pH regulator 5%, auxiliary agent: 0.02%, water: balance, variable temperature The concentrated amine is benzylethylenediamine, the pH regulator is sodium bicarbonate, and the auxiliary agent is organosiloxane defoamer.

[0028] The method of use is: the absorbent solution in the absorption tower reacts with the gas containing carbon dioxide to form a rich liquid, the absorption temperature: 40-50 ° C, the absorption pressure: 1-1.1 bar, the amount of absorbed carbon dioxide is comparable to that of benzyl ethylene di The ratio of the amount of amine substances is above 0.2. After the primary rich liquid leaves the absorption tower, it is cooled down to 25°C, and then the solids rich in carbon dioxide products are collected through a solid-liquid separator, and the separated liquid is sent back to the lean liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com