Braking circuit in alternating current loop

An AC voltage and loop technology, applied in the field of devices that control the drive motor, to achieve the effect of simplifying the control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

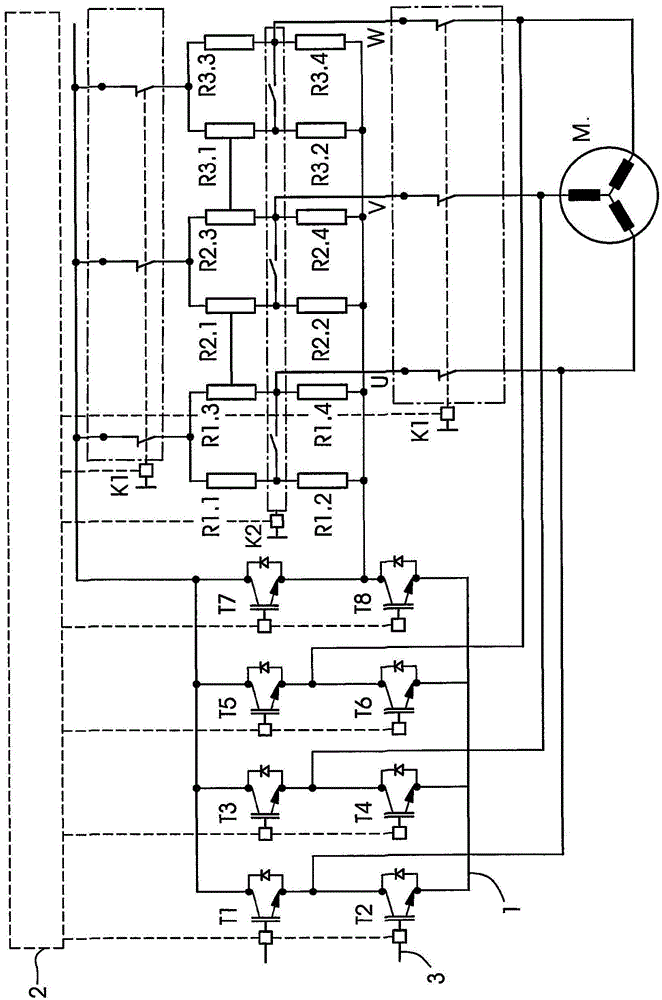

[0017] A device for controlling the drive motor M by means of the control unit 2 is shown in the drawing. Control unit 2 essentially consists of electronic circuit logic for regulating drive motor M and all switches and power semiconductors of the device. The device has an inverter 1 which is connected to a direct voltage intermediate circuit 3 . The inverter 1 can be implemented unidirectionally or bidirectionally. In the first case, the inverter 1 can only convert the DC voltage from the DC intermediate circuit 3 into an AC voltage for controlling the drive motor M. If the inverter 1 is bidirectional, it can also convert the electrical energy from the AC voltage circuit of the drive motor M into a DC voltage and feed it back into the DC intermediate circuit 3 .

[0018] The inverter 1 consists of six transistors T1 to T6 which are controlled by the control unit 2 in such a way that the desired motor voltage for controlling the drive motor M is supplied in the AC voltage ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com