Insulation wall system and breeding room

A technology for thermal insulation walls and systems, applied in thermal insulation, walls, roofs, etc., can solve problems such as unfavorable indoor thermal insulation, accelerate indoor heat, and affect the service life of structures, so as to realize modern intelligent breeding, reduce accumulation degree, and enhance thermal insulation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

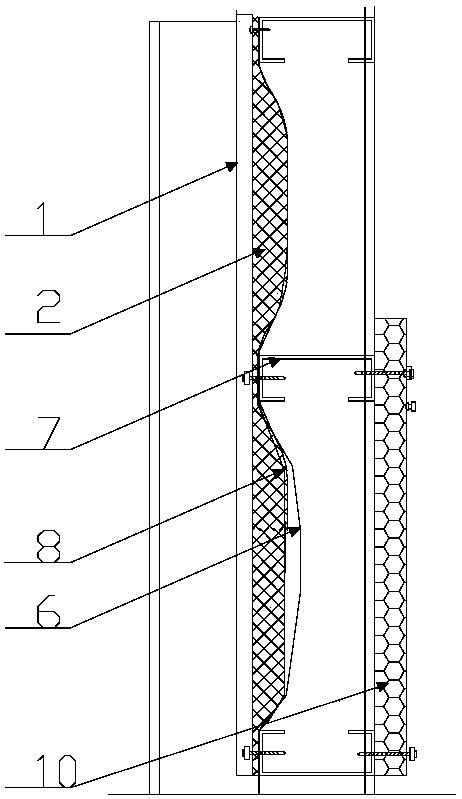

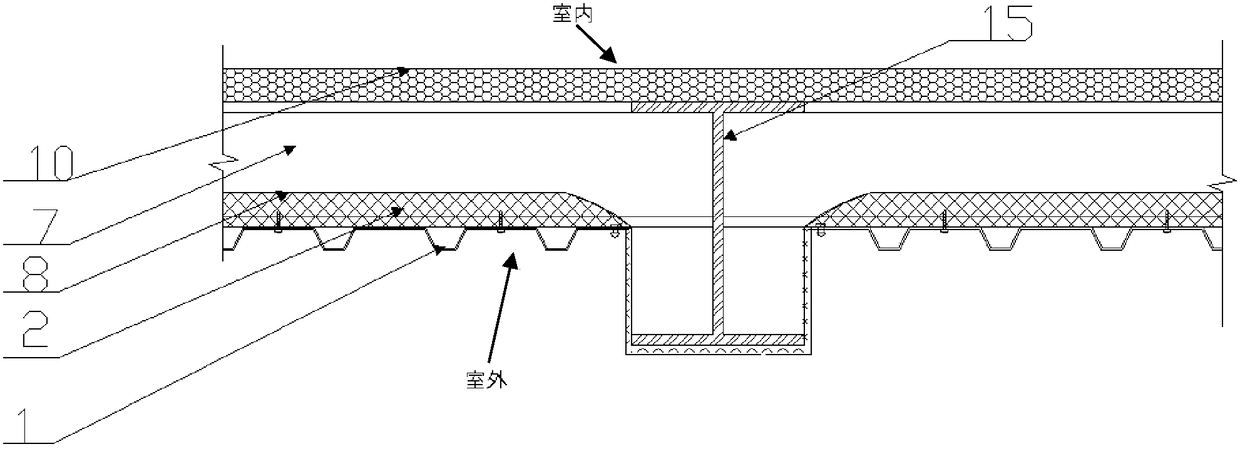

[0034] Such as Figures 1 to 2 As shown, the thermal insulation wall system of this embodiment includes a column 15, a wall surface arranged on the column, the wall surface includes connecting purlins 7, and external thermal insulation walls connected to both sides of the connecting purlins, The inner thermal insulation wall surface 10, the connecting purlin is connected to the column, wherein the inner thermal insulation wall surface is an inner flush structure. In this embodiment, the inner thermal insulation wall is made of polyurethane board or rock wool board, which makes the inner surface of the breeding room smoother; and the airtightness is much better.

[0035] Such as figure 2 As shown, in this embodiment, the inner edge of the wall purlin is arranged on the inner side of the inner edge of the column or flush with the inner edge of the column, which ensures that the inner thermal insulation wall is a plane structure. When using this thermal insulation wall system a...

Embodiment 2

[0037] On the basis of Example 1, the outer thermal insulation layer includes the first waterproof layer 8, the glass wool 2 and the profiled steel plate 1 arranged sequentially from the inside to the outside.

Embodiment 3

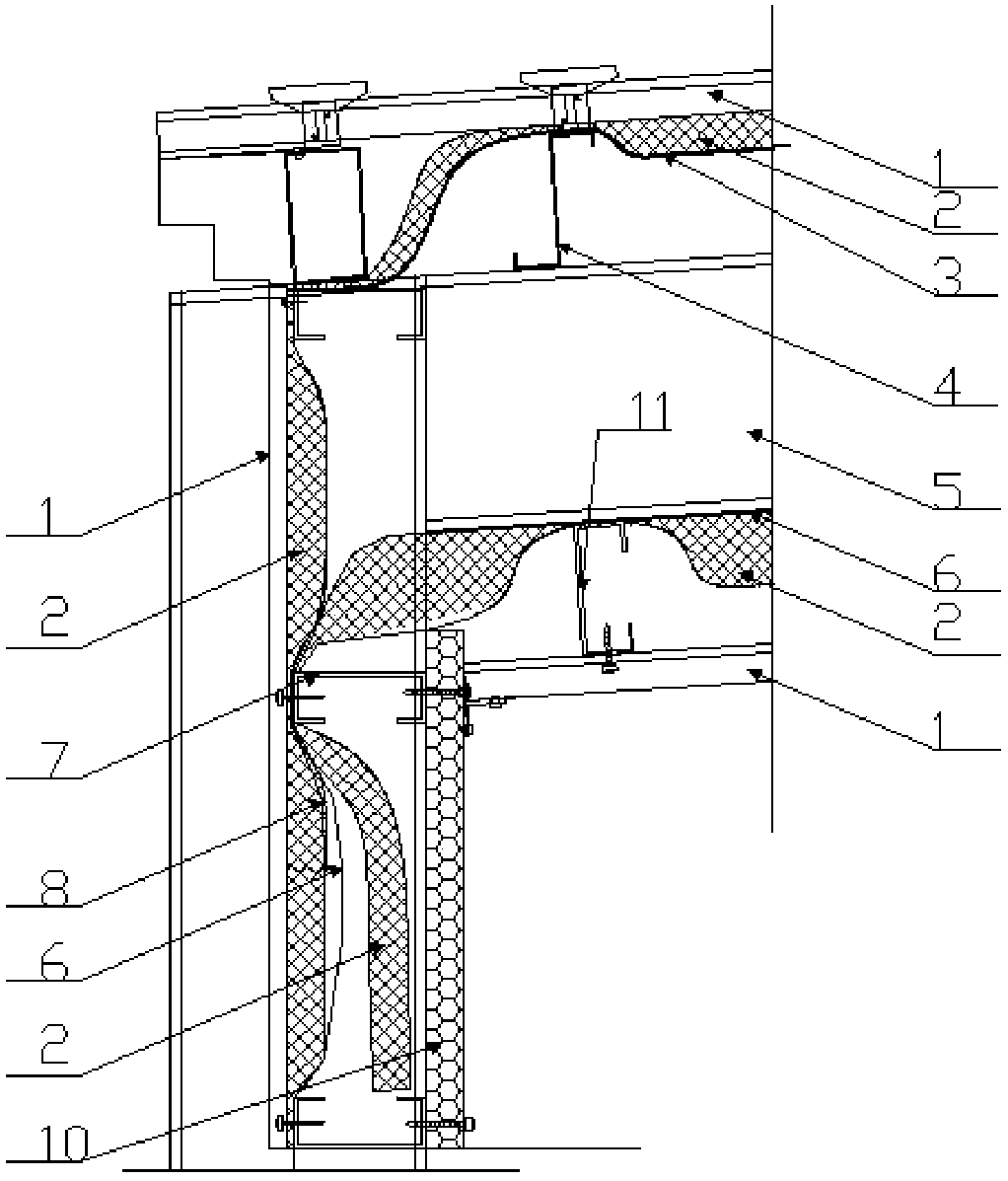

[0039] Such as image 3 As shown, the breeding house in this embodiment includes interconnected enclosure walls, a roof arranged on the enclosure walls, and the enclosure walls include facing gable walls and side walls, wherein the enclosure walls are the ones described in the above-mentioned embodiment 1 or 2. The thermal insulation wall system described above.

[0040] The roof includes a roof beam connected to the column, an outer roof structure and an inner roof structure arranged on the upper and lower sides of the roof beam 5, wherein the outer roof structure includes an outer roof panel and purlins 4 on the roof, The outer roof panel is arranged on the roof beam through purlins on the roof, and the outer roof panel includes steel wire mesh 3, glass wool 2 and upper profiled steel plate stacked from bottom to top;

[0041] The inner roof structure includes a thermal insulation surface layer, an inner roof layer and a purlin 11 under the roof, and the thermal insulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com