Fiber metal laminate fatigue delamination extension test gap processing method

A technology of fiber metal laminates and extended testing, which is applied to metal processing equipment, manufacturing tools, grinding machines, etc., can solve the problems of prepreg fracture, no description, prepreg damage, etc., and achieve the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

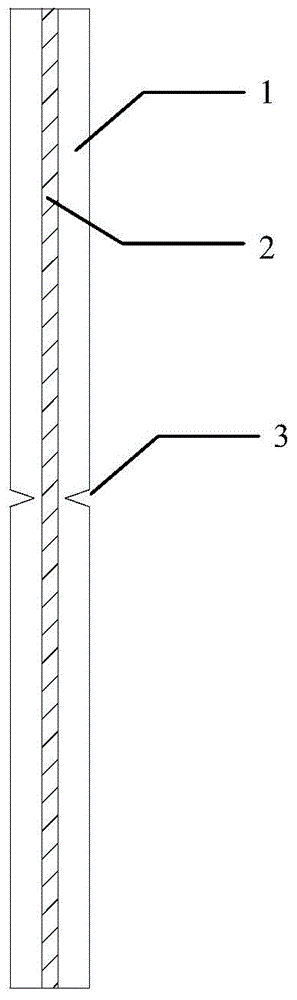

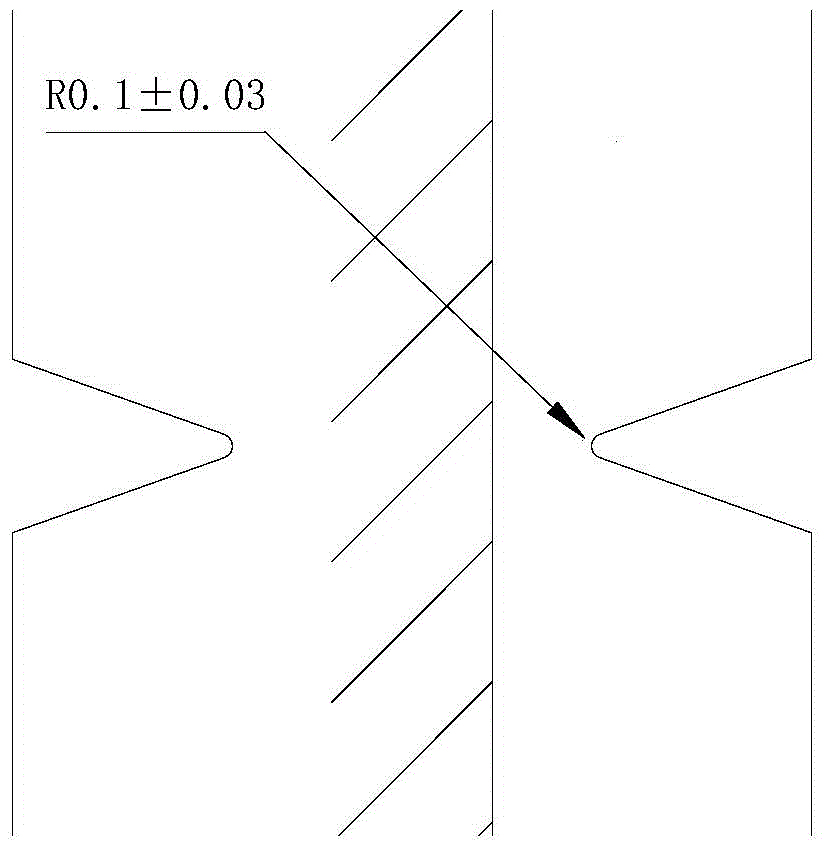

[0018] See attached Figure 1~4 As shown, in the processing method of the notch of the fatigue delamination expansion test of the fiber metal laminate, the fiber metal laminate is formed by the prepreg layer 2 impregnated with the adhesive and the metal aluminum plate 1 after overlapping and paving The laminated board 6 formed by the curing process, the fatigue delamination expansion test notch is a strip-shaped notch 3 processed on the metal aluminum plate 1 of the laminated board 6, the cross-section of the strip-shaped notch 3 is V-shaped, V-shaped The radius of curvature of the tip should be less than or equal to 0.1±0.03mm, and the distance D between the V-shaped tip and the prepreg layer 2 is less than or equal to 0.5mm. The steps of the method are:

[0019] Step 1: Clamp the laminated plate 6 on the shoulder surface of the mold 7 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com