Feeding rotary sucking gripper mechanism of fully-automatic backlight machine

A fully automatic, backlit technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve problems such as poor adaptability, and achieve the effect of improving efficiency and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

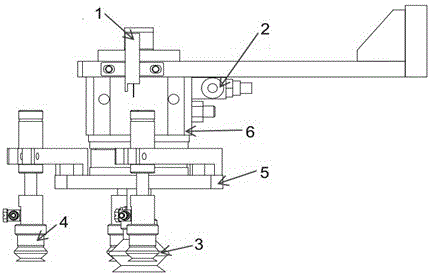

[0008] The main function of the rotary suction hand of the feeding machine is to suck up the glass from the tray and transfer it to the next station. Among them, the direction of the glass directly affects the progress of the next station. Such as figure 1 As shown, the rotary cylinder (6), the rotary cylinder is installed on the fixed plate, the side is installed with the air pipe joint (2), the position sensor (1) is installed on the upper part of the cylinder, and the suction nozzle connecting plate (5) is installed on the rotating surface of the cylinder ), the central suction nozzle (3) is installed in the middle of the connecting plate, and the adjustable suction nozzle (4) is installed on the long hole of the connecting plate.

[0009] When sucking the glass on the material tray, according to the needs, the rotating cylinder rotates at a set angle (mainly 90°). When the cylinder rotates, the center fixed suction nozzle rotates to ensure the main suction is stable, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com