Foam Processing Equipment

A processing equipment and foam technology, which is applied in the field of foam processing, can solve problems such as easy cracking of foam, and achieve the effect of high safety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

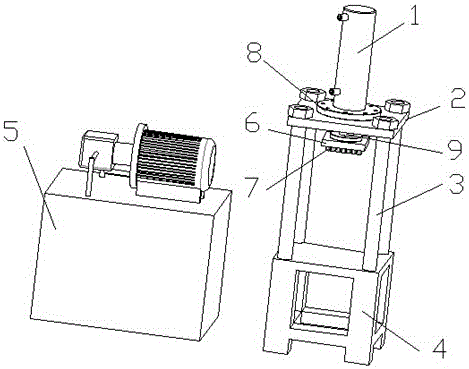

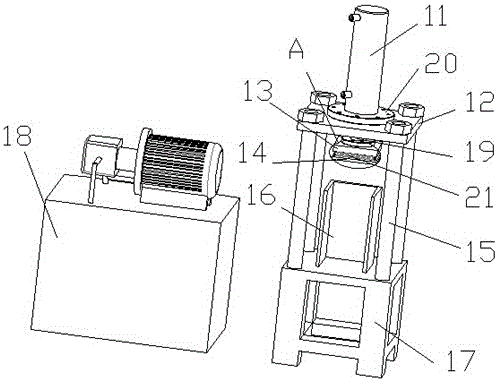

[0018] Please refer to image 3 , image 3 It is a structural schematic diagram of the foam processing equipment of the present invention. The foam processing equipment includes: an oil pump assembly 18, a hydraulic cylinder 11, a press upper plate 12, a discharge plate 14, an upper die 13, a press lower plate 16, several pillars 15 and a base 17. The oil pump assembly 18 It is connected with the hydraulic cylinder 11 and is used to provide power for the hydraulic cylinder 11. The upper platen 12 of the press is fixed on the base 17 through several pillars 15, and the telescopic rod 19 of the hydraulic cylinder 11 passes through the center hole of the upper platen 12 of the press, and is fixedly connected with the upper platen 12 of the press through a connecting piece 20 . The telescopic rod 19 is connected with the upper mold 13 . The lower platen 16 of the press is arranged directly below the unloading plate 14 for fixing the foam to be processed.

[0019] Please refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com