Manufacturing method and manufacturing device of dental floss rod

A manufacturing method and technology for manufacturing equipment, applied in the direction of metal processing, etc., can solve problems such as the impact on the user's health, the toxicity of the adhesive, and the easy falling off of the dental floss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to allow a more detailed understanding of the purpose, functions and features of the present invention, preferred embodiments are given and described below with accompanying drawings.

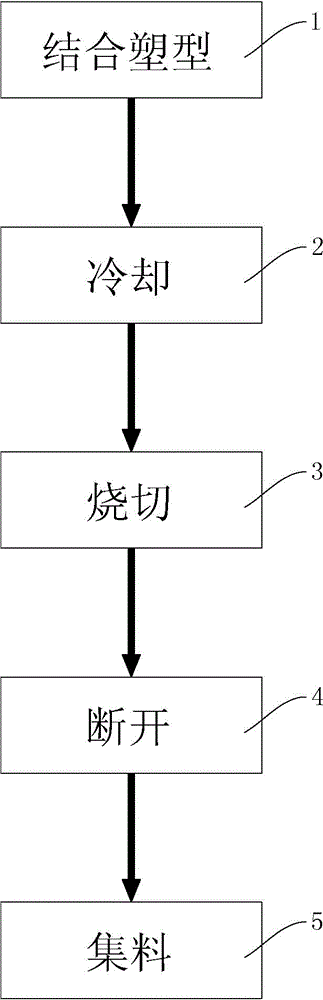

[0065] First, see figure 1 ;Depend on figure 1It can be seen that, the manufacturing method and equipment of the dental floss stick according to the present invention, the steps mainly include combining molding 1 , cooling 2 , burning 3 , breaking 4 and aggregate 5 .

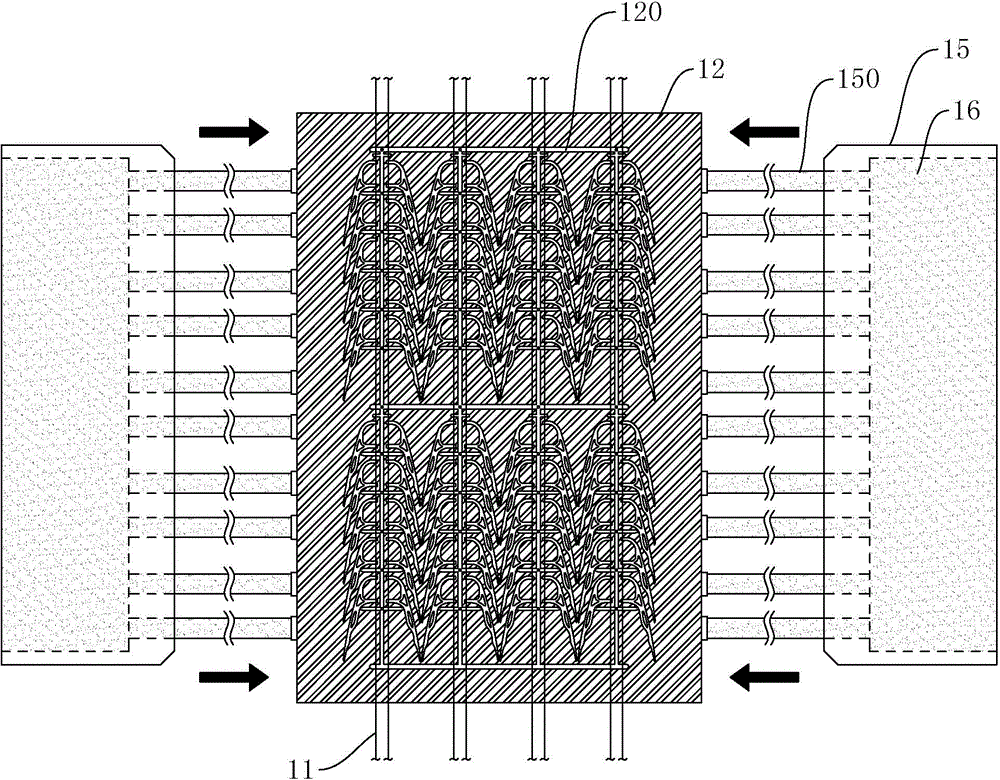

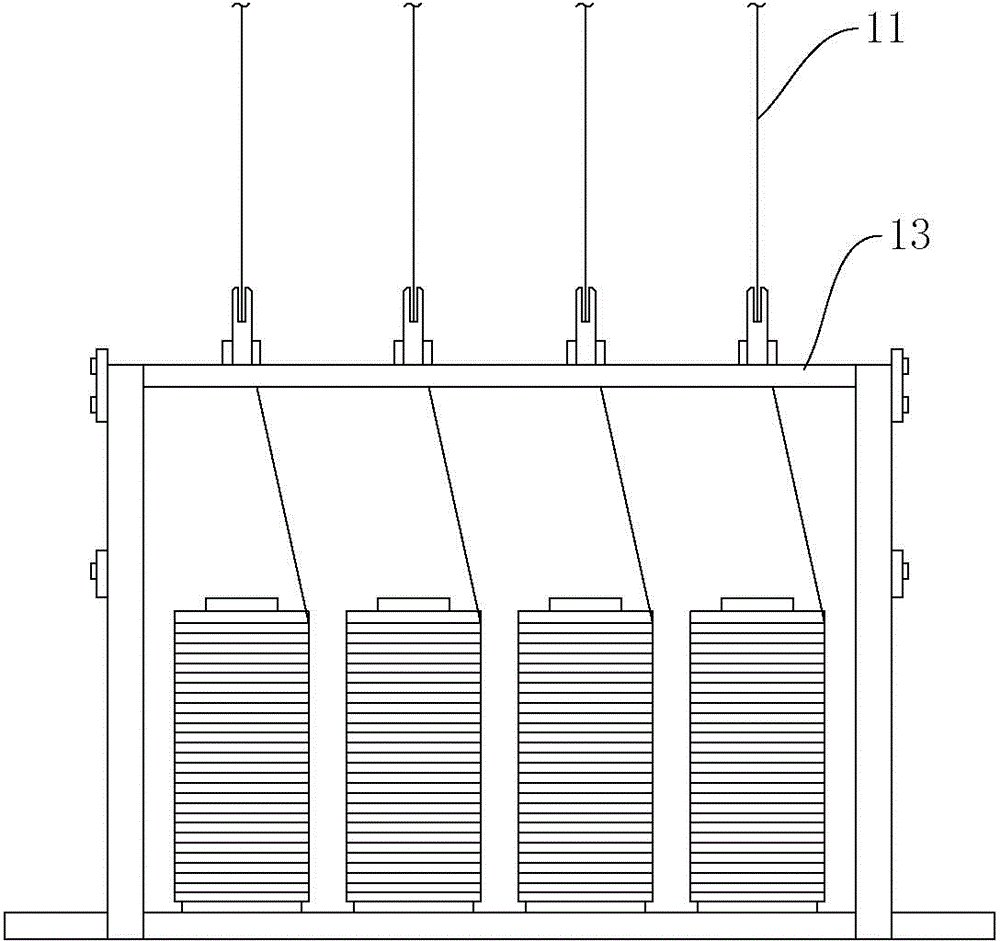

[0066] Combination modeling 1 (for coordination refer to figure 2 , image 3 and Figure 4 ): Mainly, the dental floss body 11 made of nylon, polyester, PTFE, PFA, polypropylene or polyethylene fiber is guided by the guide wire device 13, so that the pull wire device 14 is pulled to two corresponding grooves with a dental floss stick shape. 120 between the dental floss stick molds 12, continue to clamp the two dental floss stick molds 12 correspondingly to the dental floss body 11, use the injection device 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com