Reciprocating double-station stamping device

A stamping device and double-station technology, applied in stamping machines, presses, manufacturing tools, etc., can solve the problems of high manufacturing precision of hydraulic components, complex hydraulic system design, high operation and maintenance costs, etc., to achieve easy promotion and use, The effect of high degree of automation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

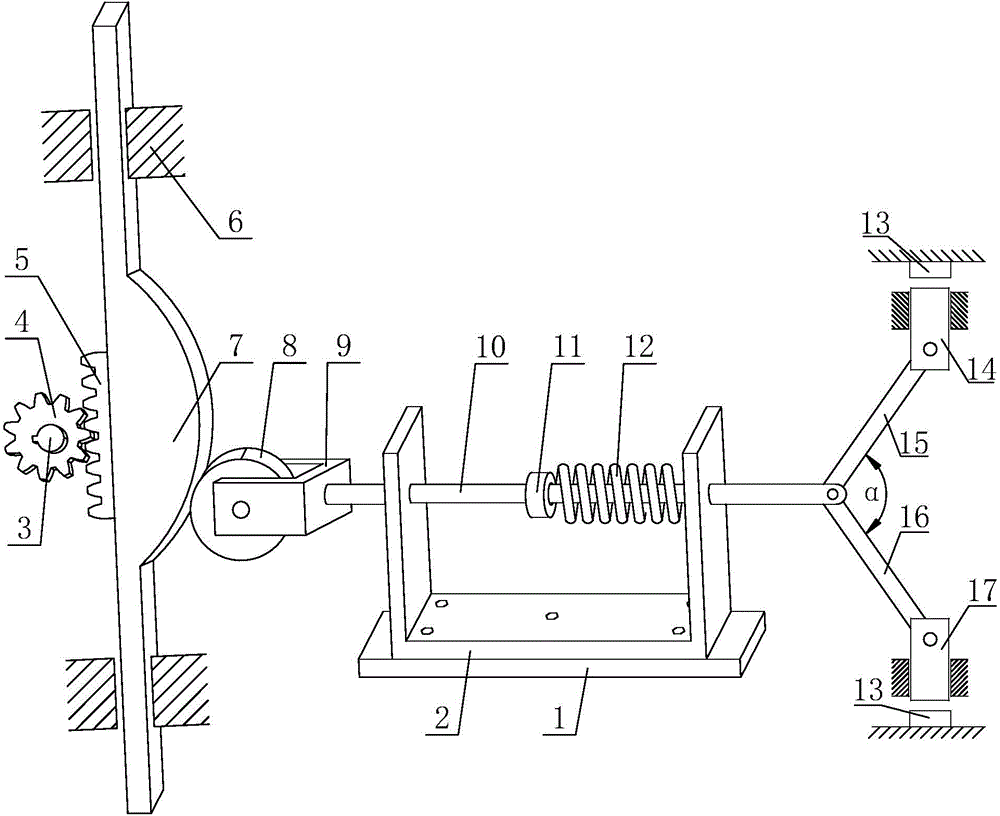

[0017] like figure 1 A reciprocating double-station stamping device shown includes a rectangular base 1 and a support 2 for supporting the push rod 10, and also includes a symmetrically arranged punching head 14 and punching head 2 17 for punching a workpiece 13; The support 2 is fixedly installed on the upper side of the rectangular base 1, and the push rod 10 is slidably installed on the support 2. The push rod 10 is provided with a return spring 12 through a stopper 11. The push rod 10 One end is rotated by a roller frame 9 and is equipped with a roller 8 that cooperates with the disc cam 7 and is used to reduce friction. The disc cam 7 is slidably installed on the mounting frame 6, and the rear side of the disc cam 7 is fixed There is a rack 5, and the end of the power shaft 3 is fixedly installed with a gear 4 meshing with the rack 5 to form a rack-and-pinion transmission pair, and the other end of the push rod 10 is respectively connected to one end of the connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com