Cutting device for cutting thin and sticky tapes, especially cord tapes

A cutting device and a technology of strips, applied in the direction of transportation and packaging, application, sending objects, etc., can solve the problem of damage to the dimensional accuracy of cord strips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

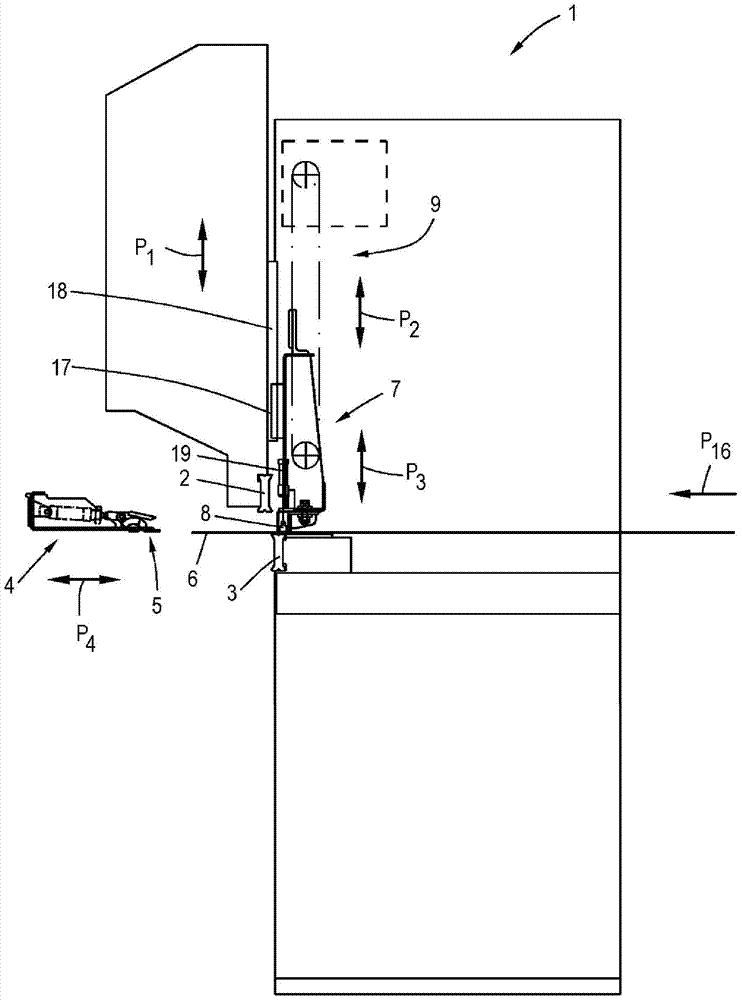

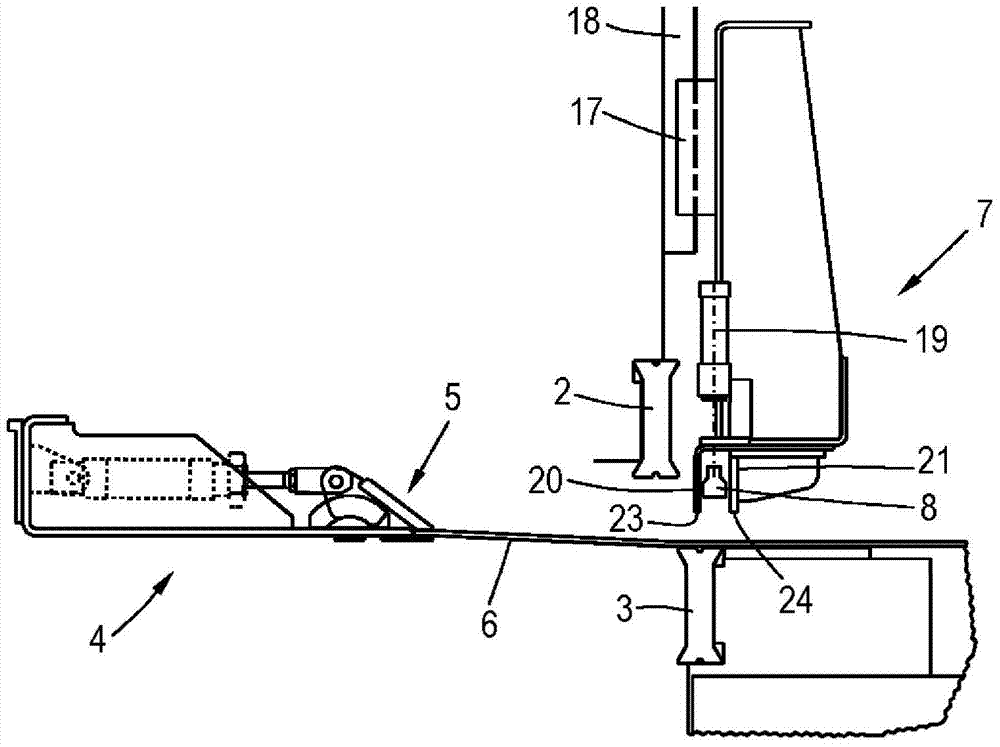

[0035] figure 1 and figure 2 A schematic diagram of a cutting device 1 according to the invention is shown for cutting thin, sticky strips such as cord strips for the manufacture of tyres. The cutting device 1 comprises as indicated by the double arrow P 1 The upper knife 2 which can move vertically and the lower knife 3 which is fixed in position are shown. A pulling device 4 is also provided, which comprises a gripping section 5 for pulling the strip section of the strip 6 to be cut past the cutting device or the two knives 2 , 3 .

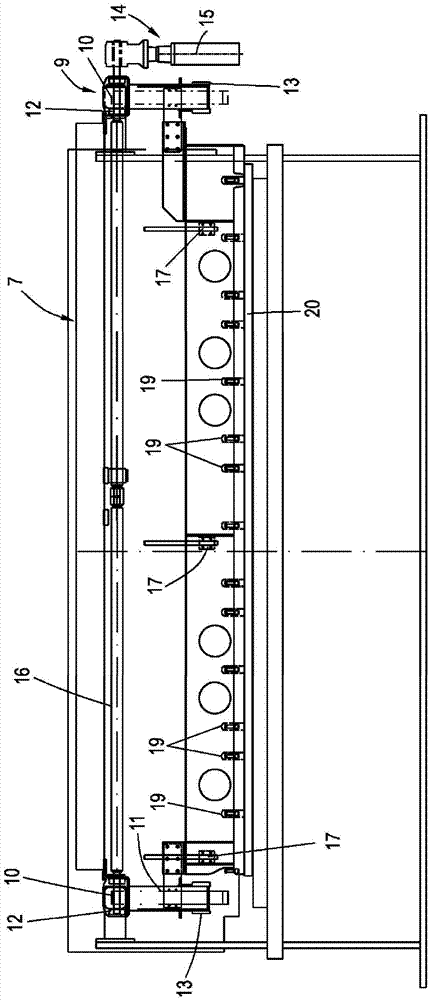

[0036] A hold-down device 7 is also provided, which includes a magnetic strip 8 for securing the strap. Pressing device 7 as indicated by the double arrow P 2 Vertical movement is possible as shown, for which a drive unit 9 is provided. In the example shown, the drive unit 9 comprises two belt drives 10 arranged on both sides of the hold-down device 7 . The belt drives 10 each comprise a belt 11 connected to the hold-down device 7 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com