Automatic material dissolving machine

A material machine and motor technology, applied in the direction of mixers, mixer accessories, chemical instruments and methods, etc., can solve the problems of low efficiency, uneven mixing, insufficient manual mixing, etc., to improve the efficiency of chemical materials, and the vertical movement is accurate , control the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

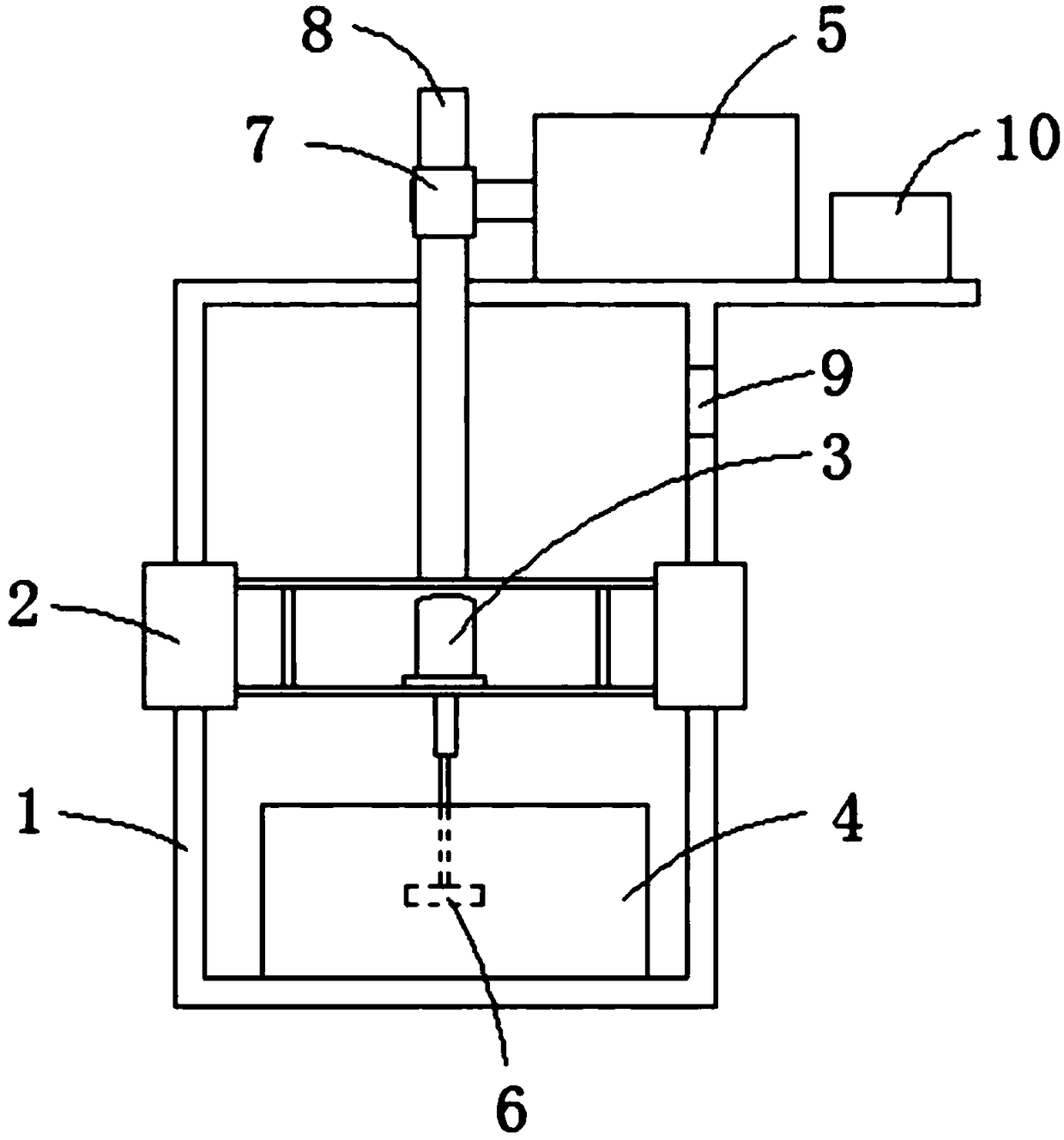

[0014] Such as figure 1 As shown, the automatic feeding machine includes a frame 1, a lifting mechanism 2, a motor 3, a material barrel 4 and a servo motor 5, and the lifting mechanism 2 can be vertically moved in the frame 1, and the lifting mechanism 2 can be vertically moved. The two ends of the mechanism 2 are respectively set on the side bars on both sides of the frame 1, the motor 3 is fixed on the lifting mechanism 2, the output shaft of the motor 3 is vertically downward, and the motor 3 A stirring paddle 6 is set on the output shaft of the output shaft; the chemical material cylinder 4 is detachably placed on the bottom of the frame 1, and the stirring paddle 6 is in the chemical material cylinder 4; the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com