Bending die assembly, bending die kneading assembly, bending machine and bending method

A technology of mold assembly and buckling machine, which is applied in the field of buckling mold assembly, and can solve problems such as poor koji making effect and poor pulp extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

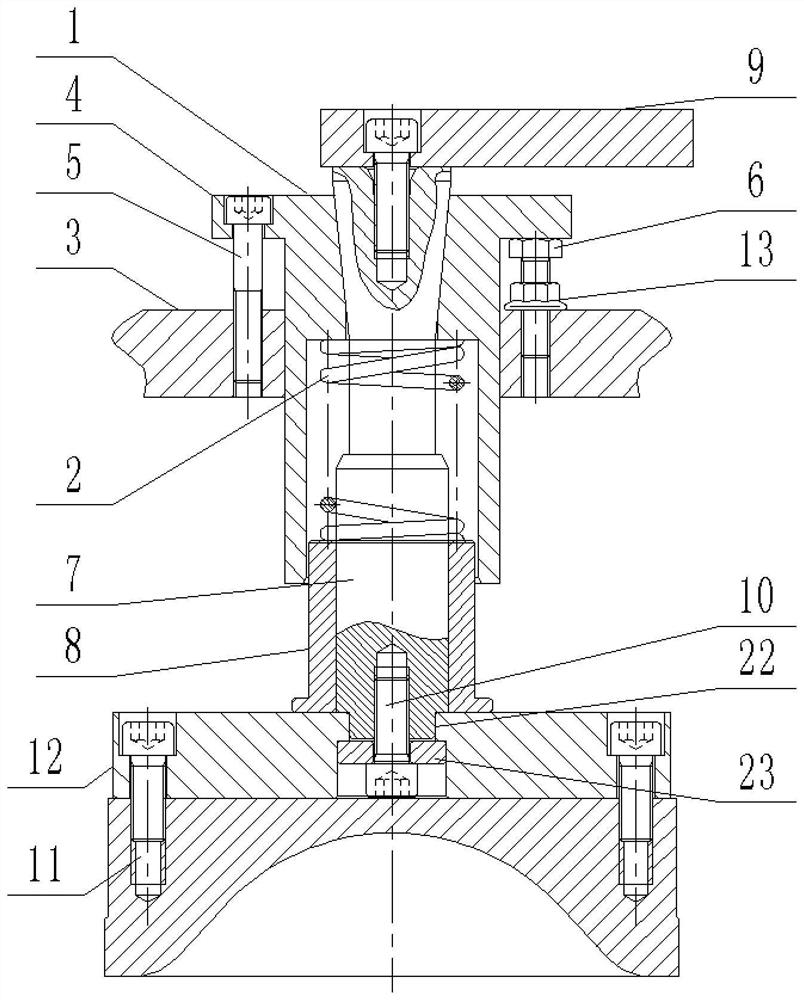

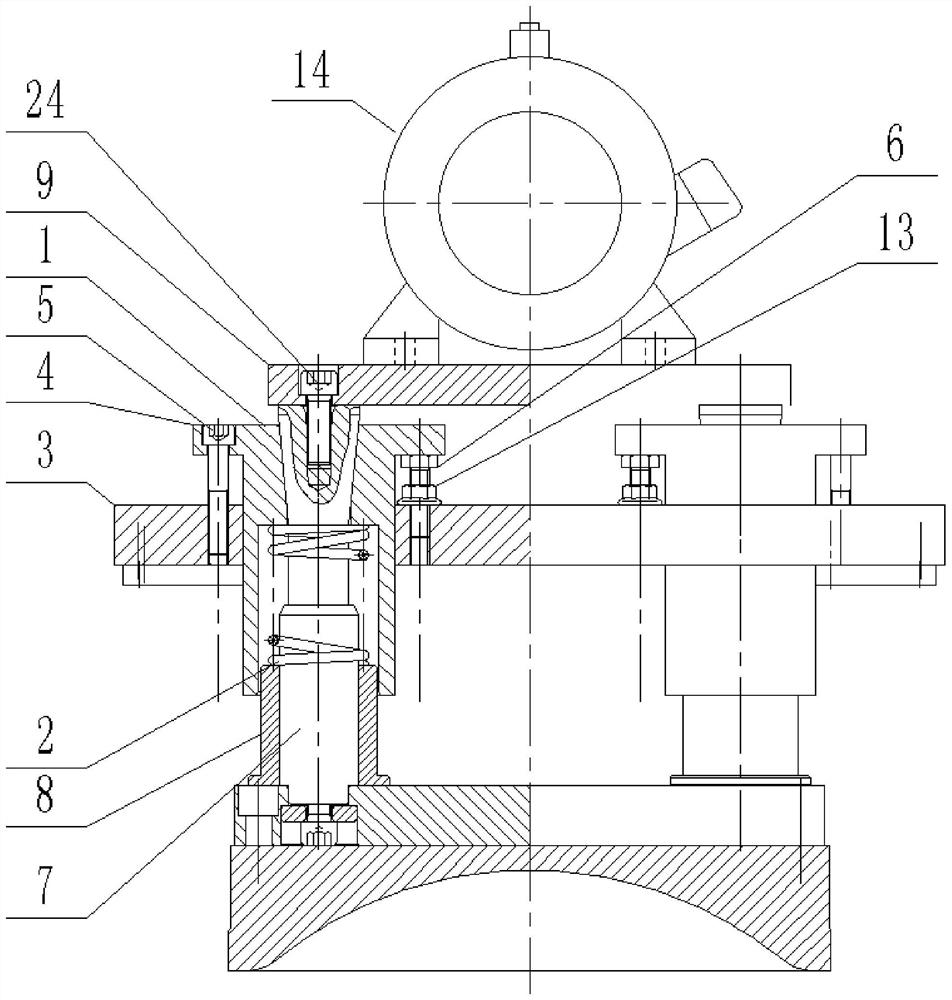

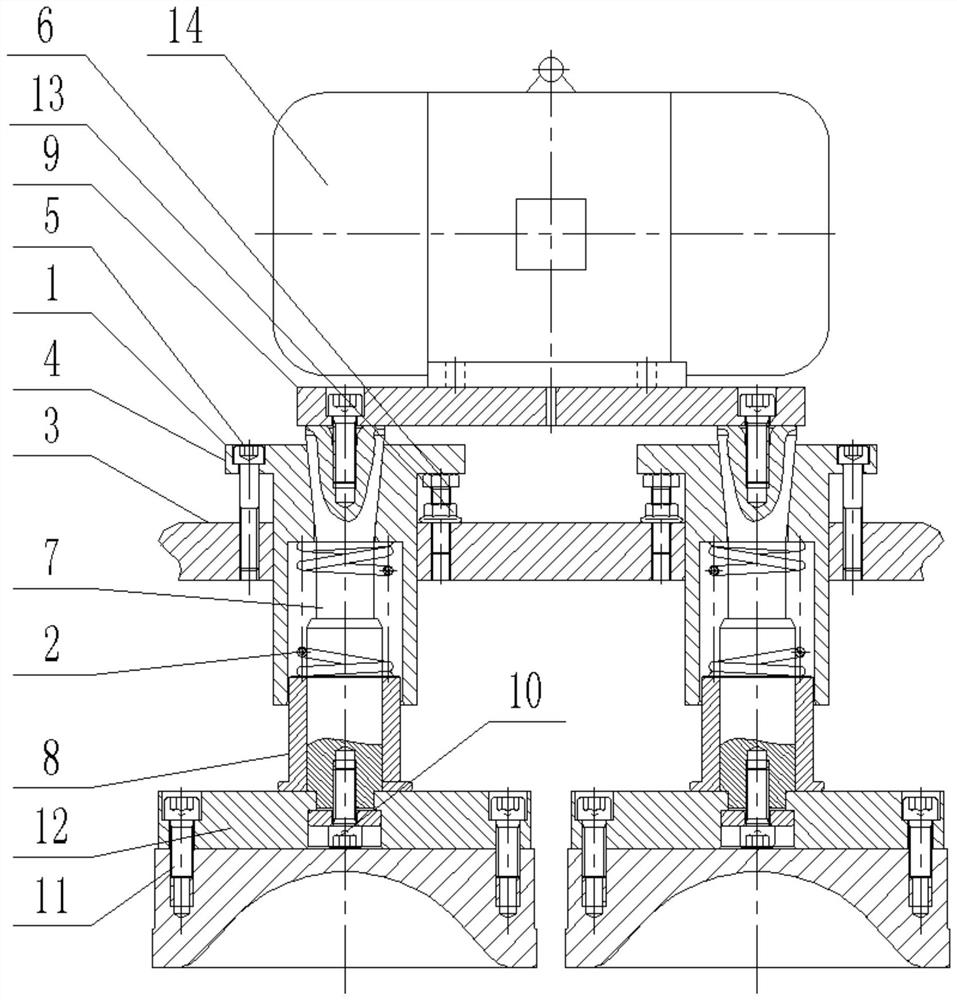

[0057] Such as figure 1 As shown, a die handle assembly of the present invention includes a die handle cover 1, a die handle that is slidably installed in the die handle cover 1 and abuts against the upper side of the inner hole of the die handle cover 1 through a spring 2, and the die handle cover 1 The joint with the mold shank is a conical fit structure, and as the spring 2 is compressed, the mold shank sleeve 1 and the mold shank are separated from the joint at the conical fit.

[0058] During use, the vibrating power source drives the mold handle, and the mold handle cover 1 is fixed on the piston rod of the oil cylinder used for pressing the die, and the bottom of the die handle is the die. When buckling, the piston rod of the oil cylinder is extended, so that the die is located in the chain box, and the bent material in the chain case is pressed and formed; at the same time, the piston rod continues to extend, the die and the handle cannot move down, and the handle cove...

Embodiment 2

[0062] In order to ensure the precise alignment between the die and the inner cavity of the chain box, it is necessary to ensure the perpendicularity of the axis of the mold handle to the bottom molding surface of the crank block; and to ensure the perpendicularity of the axis of the mold handle to the bottom molding surface of the crank block, it is necessary to ensure The verticality of the axis of the mold shank 1 attached to the mold shank relative to the bottom molding surface of the crank block. Therefore, in this embodiment, it is necessary to carry out a scheme optimization description on how to adjust the mold handle sleeve to obtain better verticality.

[0063] Such as figure 1 As shown, in the present invention, on the basis of Embodiment 1, the circumference of the outer wall of the mold shank 1 protrudes outward to form an eversion edge 4, and the eversion edge 4 is threadedly connected to the bearing surface by a plurality of fastening screws 5 3, and a pluralit...

Embodiment 3

[0069] The specific implementation structure about the mold handle is as follows:

[0070] Such as figure 1 As shown, the mold handle includes a handle core 7 and a limit sleeve 8 sleeved on the handle core 7, the spring 2 is sleeved on the handle core 7, and its two ends are respectively connected to the upper side of the inner hole of the mold handle sleeve 1. And the upper side of the limit sleeve 8 abuts, and the limit sleeve 8 is matched with the inner hole of the mold handle cover 1, and a section of the outer peripheral surface of the handle core 7 is matched with a section of the hole wall cone of the limit sleeve 8 inner hole.

[0071] Preferably, the shank 7 includes a coaxial and sequentially connected equal-diameter matching section, an equal-diameter transition section, and a conical conical fit with the limiting sleeve 8. The inner hole of the limiting sleeve 8 includes The tapered holes that are coaxial and sequentially connected with the circular frustum secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com