Flexible self-balance multi-suspension-point hanging beam structure

A self-balancing, multi-hoisting point technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of single hanging beam function, excessive hanging beam deflection, poor balance performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The flexible self-balancing multi-suspension point suspension beam structure of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

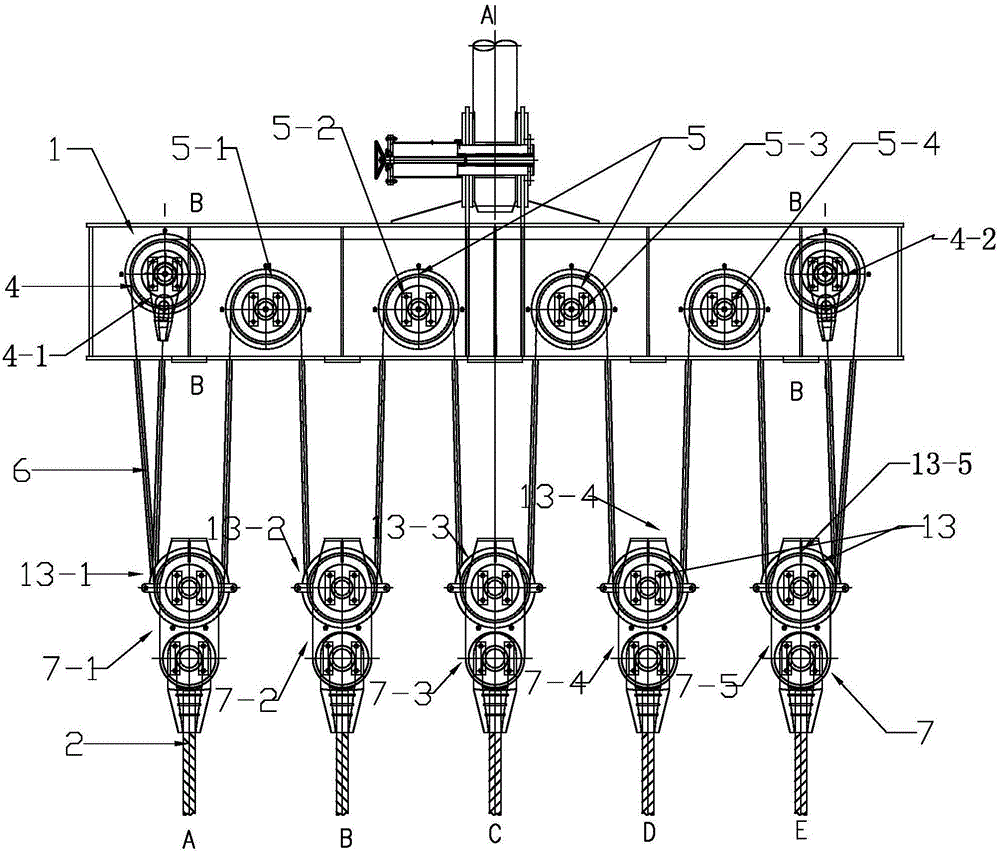

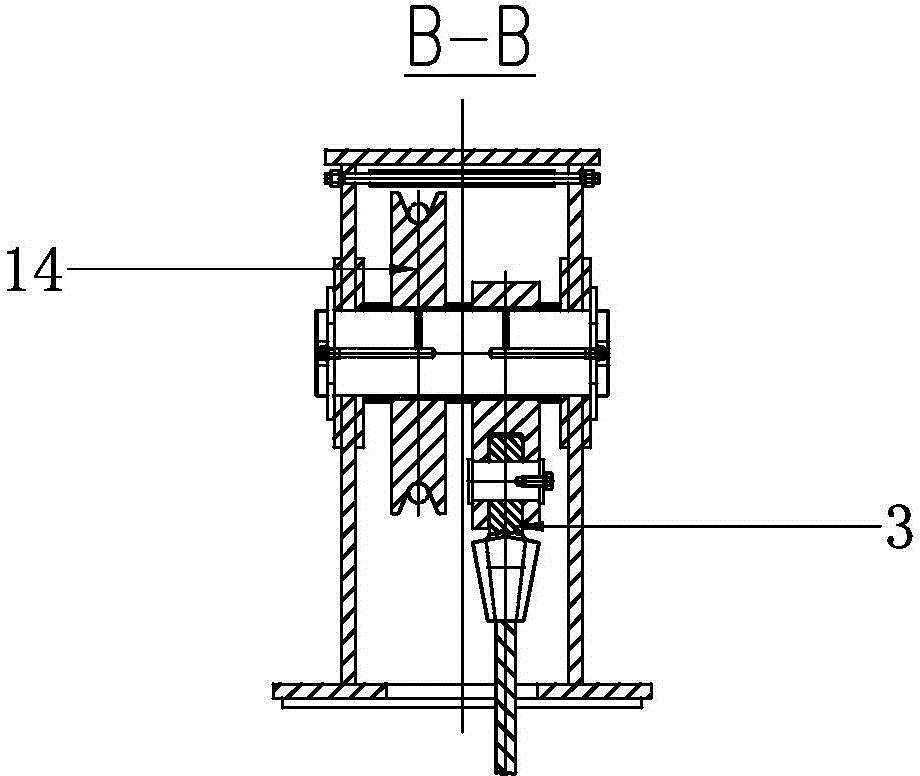

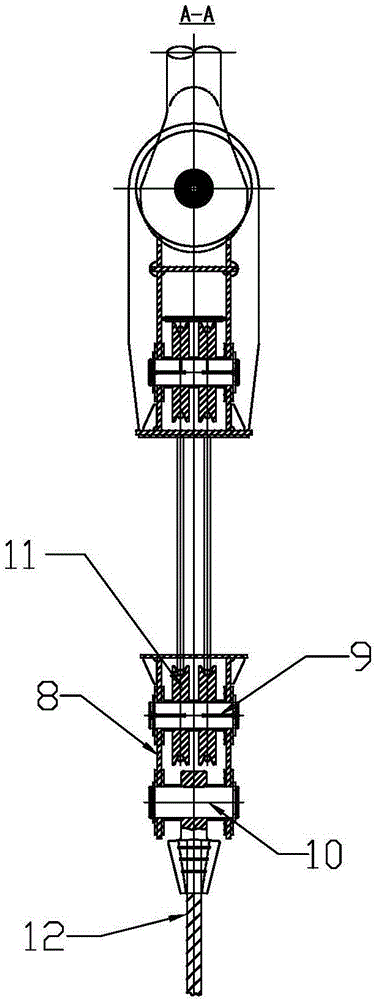

[0013] Such as figure 1 As shown, the flexible self-balancing multi-suspension point suspension beam structure of the present invention includes a beam 1 of a box structure and a steel wire rope 6 capable of connecting each suspension point 2 in series. The fixed end 4-1 of the steel wire rope and the fixed end 4-2 of the steel wire rope are arranged with a fixed pulley 5 located in the cavity of the beam 1 between the two fixed ends 4 of the steel wire rope. In this embodiment, the fixed pulley 5-1 and the fixed pulley 5 -2, fixed pulley 5-3 and fixed pulley 5-4, certainly the quantity of fixed pulley and movable pulley among the present invention can be many groups of arbitrary values; Wherein, fixed pulley 5 is evenly arranged in pairs in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com