Spinning method of woolen spinning system for spinning wrap yarns

A technology of covering yarn and spinning, which is applied to spinning machines, yarn, textiles and papermaking, etc. It can solve the problem of lack of natural fiber characteristics on the surface of the yarn, and achieve good heat preservation, simple process steps and good hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

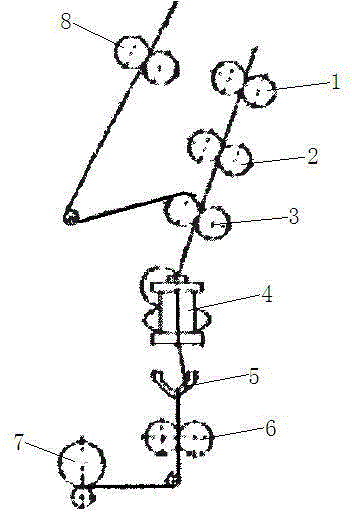

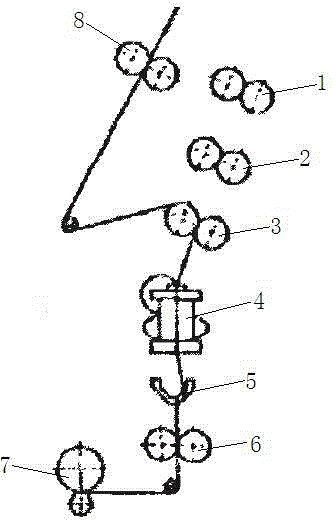

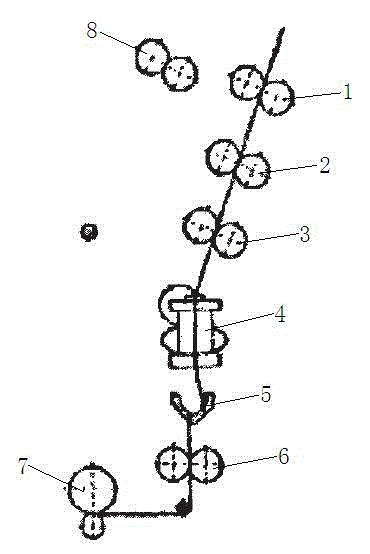

[0017] The drafting device among the present invention comprises back roller 1, middle roller 2 and front roller 3 successively from top to bottom, and back roller 1, middle roller 2 and front roller 3 are arranged obliquely.

[0018] like figure 1 As shown, the specific steps of the first type of spinning method of the present invention are: the chemical fiber filament does not pass through the drafting device, and is directly fed into the hollow spindle 4 from the front roller 3 by the feed roller 8, and the bobbin of capillary yarn is covered on the hollow spindle. 4, and rotate together with the hollow spindle 4, wound on the filament, the false twisted material 5 is wound on the groove drum 7 through the output roller 6, and the yarn-wrapped yarn of the capillary yarn wrapped with the chemical fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com