A wind heat pressure induced multi-channel ventilation and heat insulation system

A multi-channel and channel technology, applied in vertical pipes, building components, thermal insulation, etc., can solve the problems of ineffective and reasonable utilization of outdoor wind, insufficient solar energy inducing ability, and increased maintenance and repair difficulty, achieving good application prospects, strengthening Natural ventilation capacity, significant energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

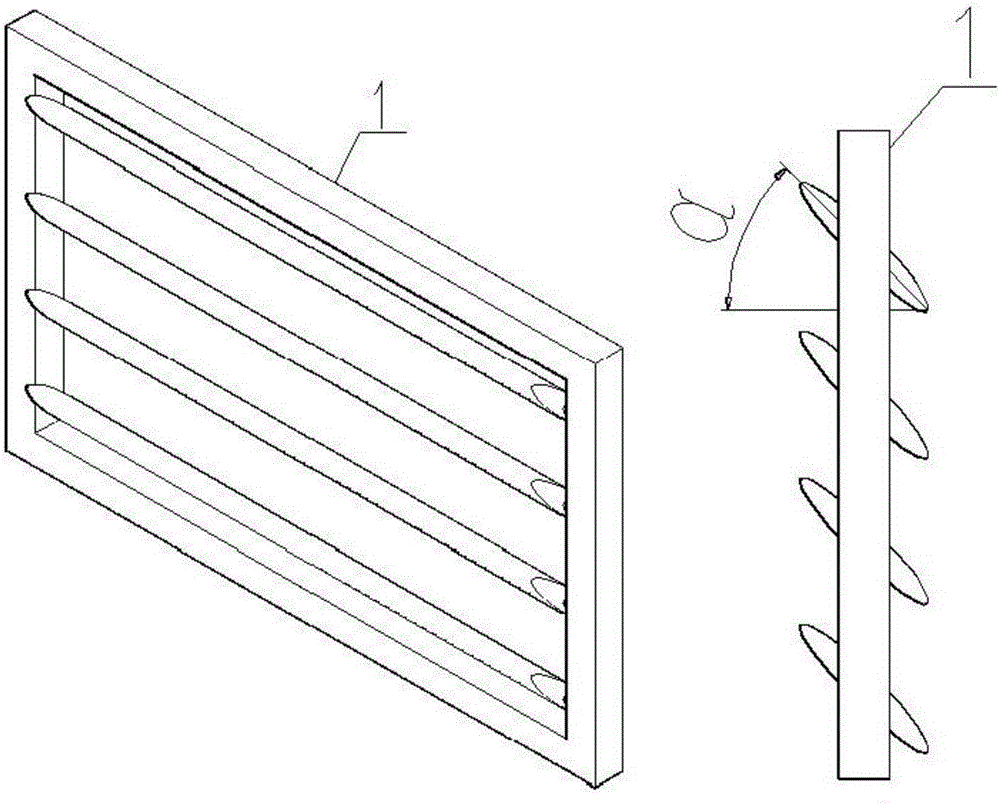

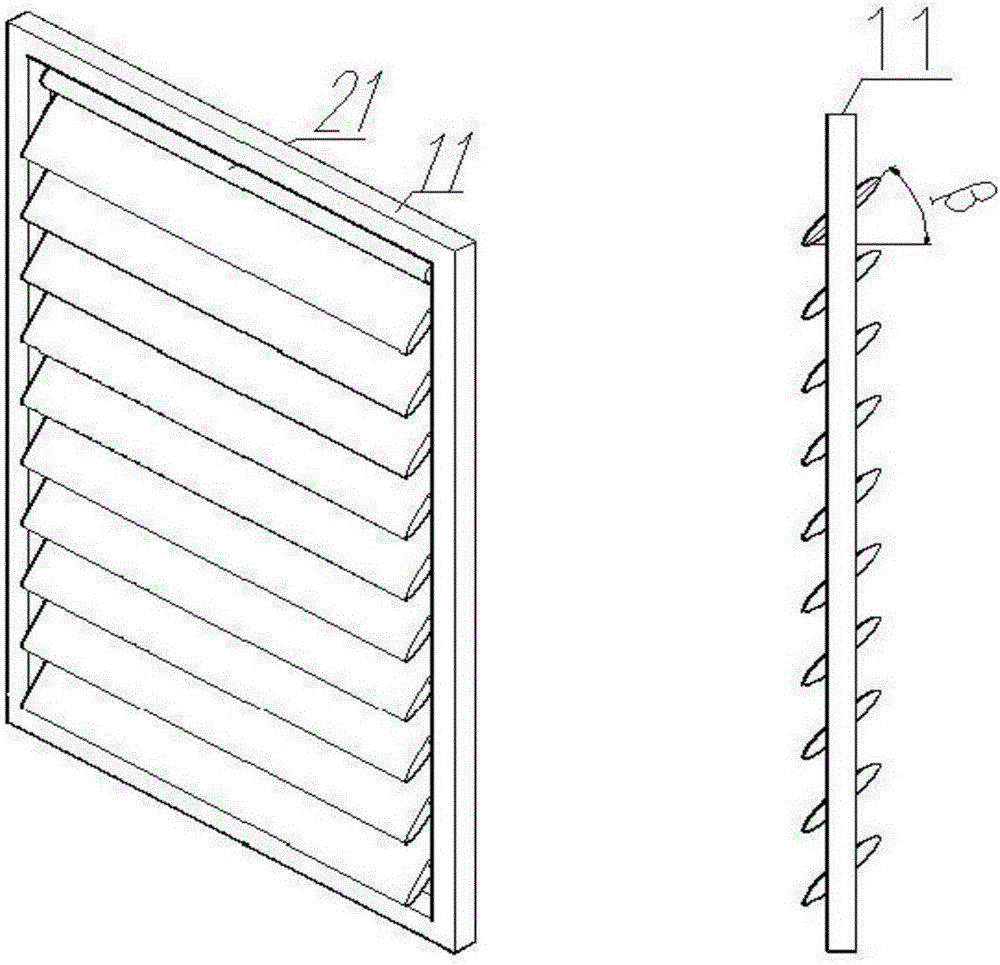

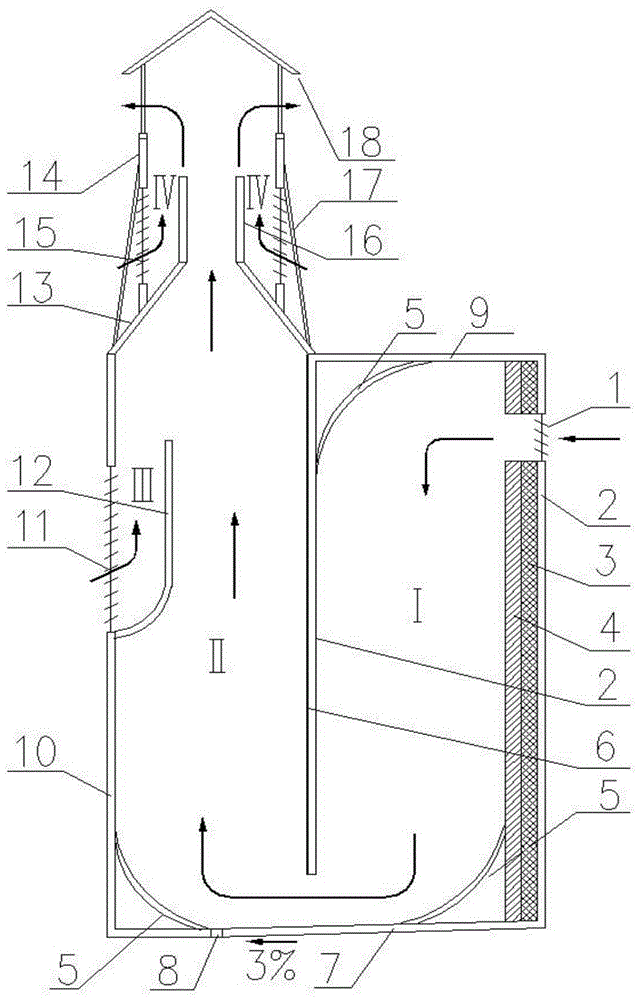

[0039] refer to figure 1 As shown, the present invention includes two main airflow passages I, II and two outdoor air induction passages III, IV, wherein the main airflow passage I is set between the heat insulation layer 4 and the left partition 2, and the main airflow passage II is set Between the heat-absorbing layer 6 and the glass cover plate 10, 1 is the louver tuyere, and there is an insulating layer 3 and a right partition 2 on the outer side of the heat-insulating layer 4 of the main airflow channel I, and a deflector 5 is arranged on the top top plate 9, Above the channels I and II are the top plate 9 and the sky round place 13 respectively. Below the channels I and II, deflectors 5 are set and fixed on the bottom plate 7. The bottom plate is provided with a sealing rubber strip 8, and the heat-absorbing layer is coated with black chrome. The thickness of the coating is 0.18mm, the insulation layer is made of rubber and plastic, the thickness is 25mm, the heat insula...

Embodiment approach 2

[0053] refer to figure 1 As shown, the present invention includes two main airflow passages I, II and two outdoor air induction passages III, IV, wherein the main airflow passage I is set between the heat insulation layer 4 and the left partition 2, and the main airflow passage II is set Between the heat-absorbing layer 6 and the glass cover plate 10, 1 is the louver tuyere, and there is an insulating layer 3 and a right partition 2 on the outer side of the heat-insulating layer 4 of the main airflow channel I, and a deflector 5 is arranged on the top top plate 9, Above the channels I and II are the top plate 9 and the sky round place 13 respectively. Below the channels I and II, deflectors 5 are set and fixed on the bottom plate 7. The bottom plate is provided with a sealing rubber strip 8, and the heat-absorbing layer is coated with black chrome. The thickness of the coating is 0.18mm, the insulation layer is made of rubber and plastic, the thickness is 25mm, the heat insula...

Embodiment approach 3

[0067] refer to figure 1 As shown, the present invention includes two main airflow passages I, II and two outdoor air induction passages III, IV, wherein the main airflow passage I is set between the heat insulation layer 4 and the left partition 2, and the main airflow passage II is set Between the heat-absorbing layer 6 and the glass cover plate 10, 1 is the louver tuyere, and there is an insulating layer 3 and a right partition 2 on the outer side of the heat-insulating layer 4 of the main airflow channel I, and a deflector 5 is arranged on the top top plate 9, Above the channels I and II are the top plate 9 and the sky round place 13 respectively. Below the channels I and II, deflectors 5 are set and fixed on the bottom plate 7. The bottom plate is provided with a sealing rubber strip 8, and the heat-absorbing layer is coated with black chrome. The thickness of the coating is 0.18mm, the insulation layer is made of rubber and plastic, the thickness is 25mm, the heat insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com