Drum brake

A drum brake and brake technology, applied in the direction of drum brakes, brake types, brake parts, etc., can solve the problems of complex structure, shortened service life of drum brakes, inconvenient loading and unloading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

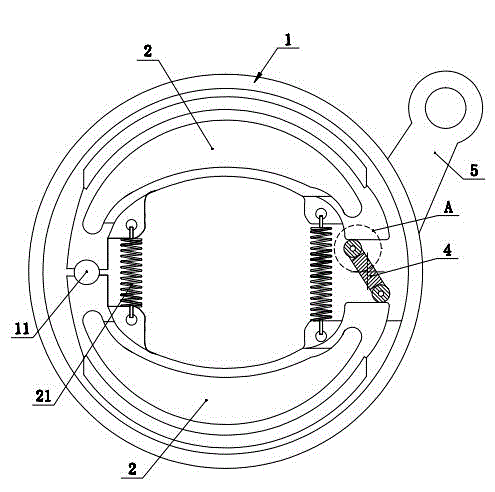

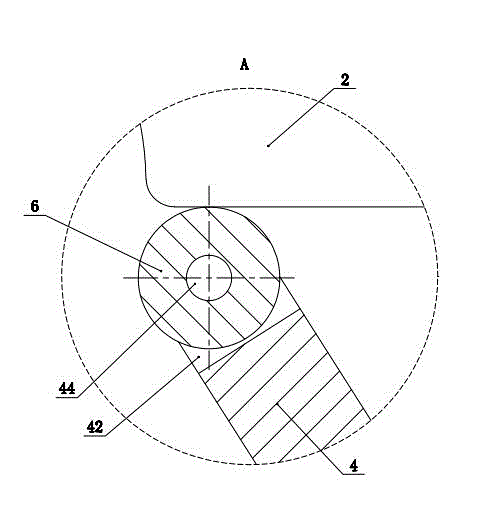

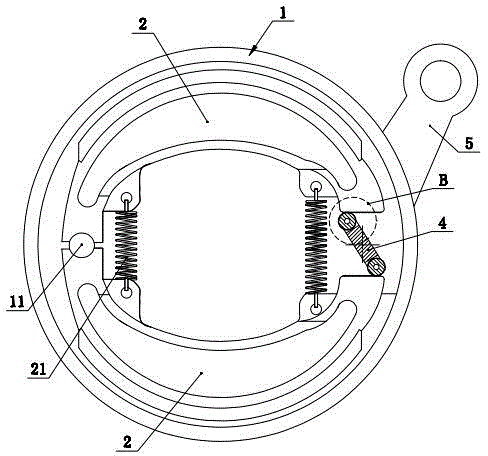

[0025] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, and 11 show a drum brake, including a housing 1, a brake camshaft 3 and two brake shoes placed in the housing 1 2. The outer end of the brake camshaft 3 located outside the housing 1 is in transmission connection with the brake arm 5 that drives it to rotate. Formed rectangular block 4, the two long sides 43 and the two short sides 41 of the rectangular block 4 can be a traditional planar structure, and certainly can be an arc structure, between the long side 43 and the short side 41 The arc surface transition connection is preferred. The two brake shoes 2 are symmetrically arranged, and the housing 1 is provided with a boss 11, and one end of the two brake shoes 2 forms a hinged rotation fit with the boss 11, and the other end of the two brake shoes 2 is an expansion brake. end, the rectangular block 4 is located between the expansion brake ends of the two brake shoes 2, and a return tension spring 21 is also provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com