Oil tube connection part

A technology for connectors and oil pipes, which is applied in the direction of pipes/pipe joints/pipe fittings, sealing surface connections, passing components, etc. It can solve the problems of motor vehicles that are prone to danger and oil pipes slipping, and achieve the effect of preventing self-slipping and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

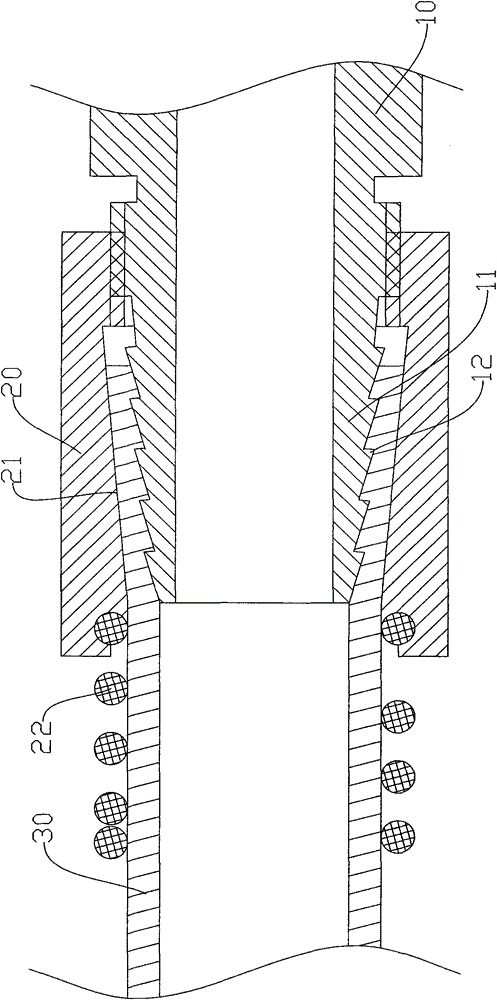

[0011] Examples, see figure 1 Shown: the oil pipe connector, including the oil pressure seat joint 10 used to connect with the oil pipe 30 . Specifically, the oil pressure seat joint 10 is provided with a conical head 11 , and the oil pipe 30 is sleeved on the conical head 11 . At the same time, a tightening nut 20 is screwed on the oil pressure seat connector 10 , and the tightening nut 20 is provided with a tapered hole 21 matched with the tapered head 11 . The so-called match means that there is a certain difference between the taper of the tapered hole 21 and the taper of the tapered head 11, so that as the tightening nut 20 and the oil pressure seat joint 10 tighten, the tapered hole 21 and the tapered The gap between the heads 11 is getting smaller and smaller. In this way, the extrusion force given by the tapered hole 21 to the end of the oil pipe 30 that is sleeved on the tapered head 11 is getting larger and larger, so that the oil pipe 30 is firmly fixed on the tap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com