Bagasse burning boiler

A boiler and bagasse technology, which is applied in the field of boilers using bagasse as fuel, can solve the problems of blockage of the grate hole of the bagasse-burning boiler, boiler explosion, etc., and achieve the effect of improving economy and reliability and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

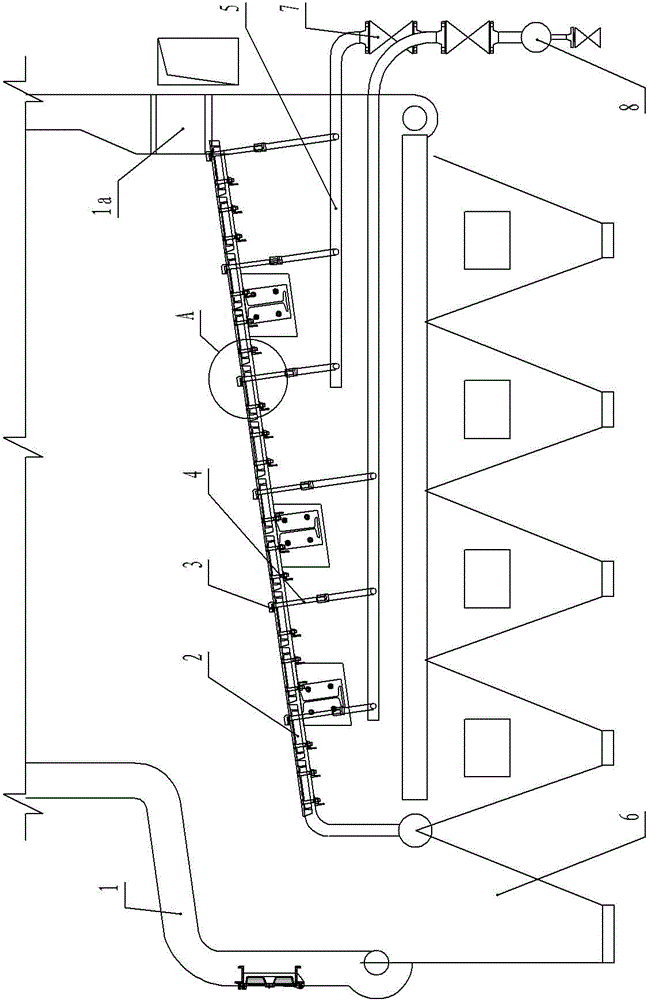

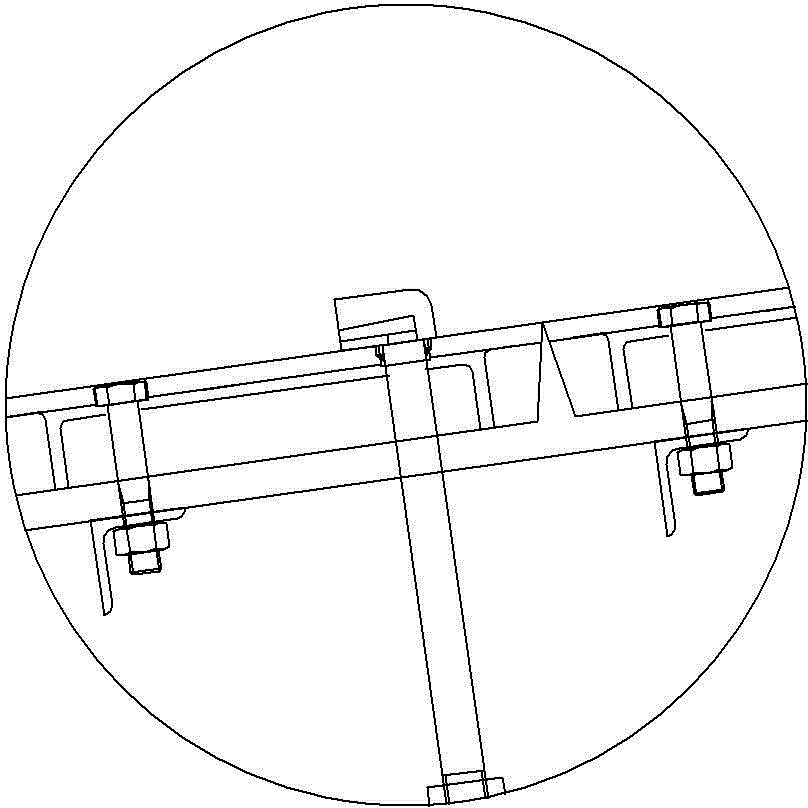

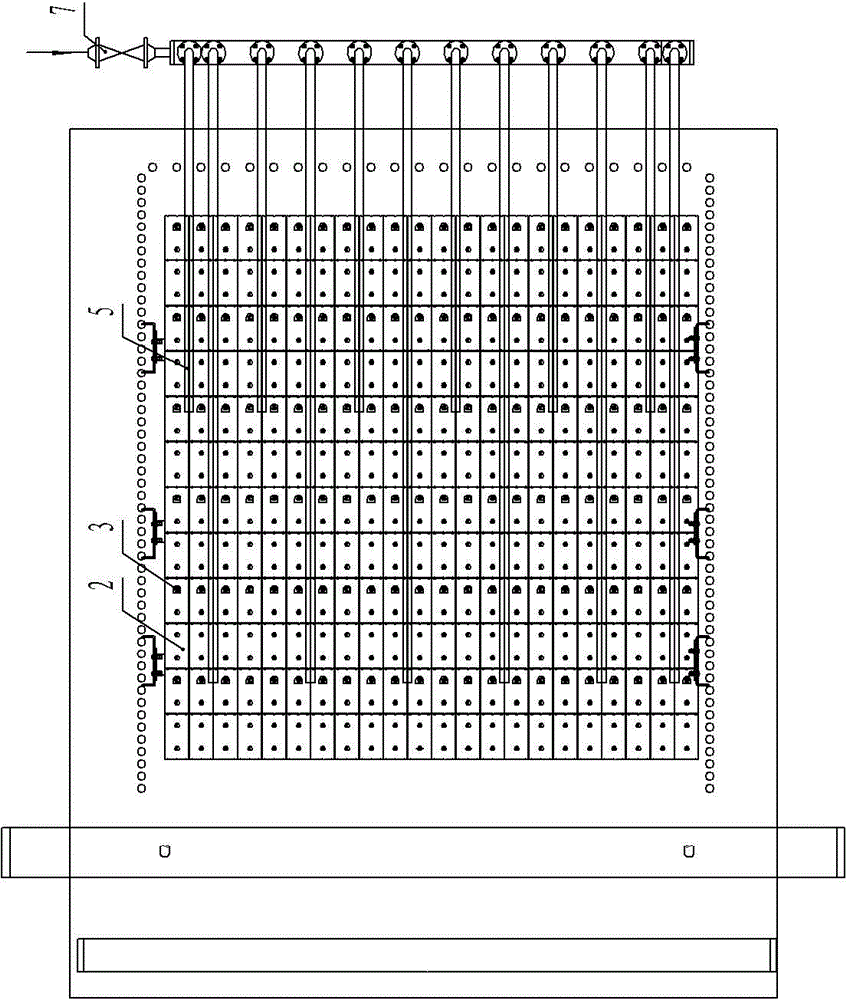

[0015] figure 1 The shown bagasse-burning boiler includes a boiler body 1, which is provided with a feed port 1a communicating with the combustion chamber, and a fire grate 2 is arranged in the combustion chamber, and the fire grate 2 is spliced by a plurality of fire grate pieces with through holes. There are gaps between the grate pieces, the grate 2 is arranged obliquely, and the angle between the grate 2 and the horizontal direction is 5°; the front end of the grate 2 is close to the feed port 1a and is higher than the end of the grate 2, and the grate 2. A receiving hopper 6 is arranged below the end, and a nozzle 3 connected to the steam pipe 5 through the nozzle 4 is arranged on the fire grate 2, and the nozzle 3 faces the end of the fire grate 2; Pressure valve 8.

Embodiment 2

[0017] The angle between the fire grate 2 and the horizontal direction is 10°; the rest are the same as in the first embodiment.

[0018] In the process of bagasse burning in the present invention, the hot air flow forms an air film to support the sand, and the sand is in a loose state. When the sand has a certain thickness, it is automatically controlled by the solenoid valve to regularly spray the sand and sand, so as not to block the grate holes. To ensure the normal operation of the boiler. The bagasse which is a natural resource can be rationally used as the fuel of the boiler, and the economy and reliability of the boiler can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com