Combined tooth type inner grooved copper tube

A technology of internal threads and copper tubes, which is applied in the field of heat transfer tubes, can solve the problems of low heat exchange rate of refrigerants and increased flow resistance of refrigerants, and achieve the effects of reducing flow resistance, increasing heat exchange rate, and increasing heat transfer surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

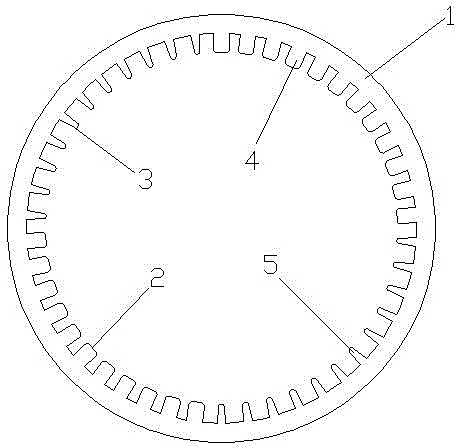

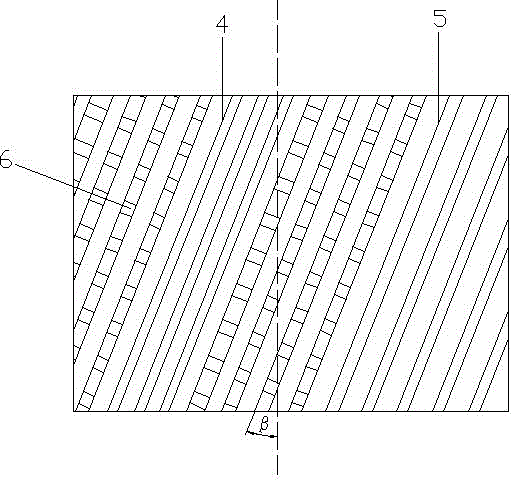

[0026] Embodiment 1: as figure 1 A combined tooth-shaped internally threaded copper pipe is shown, which includes a copper pipe body 1. The inner wall of the copper pipe body is sequentially provided with four groups of spirally distributed tooth ribs along the circumferential direction, which are tooth rib A2, tooth rib B3, tooth rib a4, tooth rib b5, on any section of the copper pipe body, the arc surfaces of tooth rib A, tooth rib B, tooth rib a, and tooth rib b each occupy a central angle of 90°, and the sections of tooth rib A and tooth rib a are as follows: Rectangular structure, the cross-section of tooth rib B and tooth rib b is triangular, the tooth top angles of tooth rib B and tooth rib b are rounded, tooth rib A, tooth rib B, tooth rib a, tooth rib b are in line with the axis of the copper tube body The included angle β is 25°.

Embodiment 2

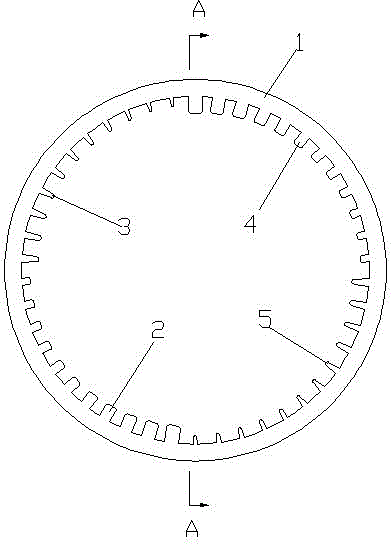

[0027] Embodiment 2: as figure 2 A combined tooth-shaped internally threaded copper pipe is shown, which includes a copper pipe body 1. The inner wall of the copper pipe body is sequentially provided with four groups of spirally distributed tooth ribs along the circumferential direction, which are tooth rib A2, tooth rib B3, tooth rib a4, tooth rib b5, on any section of the copper pipe body, the arc surfaces of tooth rib A, tooth rib B, tooth rib a, and tooth rib b each occupy a central angle of 90°, and the sections of tooth rib A and tooth rib a are as follows: Rectangular structure, the cross-section of tooth rib B and tooth rib b is triangular, the tooth top angles of tooth rib B and tooth rib b are rounded, tooth rib A, tooth rib B, tooth rib a, tooth rib b are in line with the axis of the copper tube body The included angle β is 25°; the tooth top heights of tooth rib A, tooth rib B, tooth rib a, and tooth rib b respectively decrease from the first line to the last line...

Embodiment 3

[0028] Embodiment 3: as Figure 4A combined tooth-shaped internally threaded copper pipe is shown, which includes a copper pipe body 1. The inner wall of the copper pipe body is sequentially provided with four groups of spirally distributed tooth ribs along the circumferential direction, which are tooth rib A2, tooth rib B3, tooth rib a4, tooth rib b5, on any section of the copper pipe body, the arc surfaces of tooth rib A, tooth rib B, tooth rib a, and tooth rib b each occupy a central angle of 90°, and the sections of tooth rib A and tooth rib a are as follows: Rectangular structure, the cross-section of tooth rib B and tooth rib b is triangular, the tooth top angles of tooth rib B and tooth rib b are rounded, tooth rib A, tooth rib B, tooth rib a, tooth rib b are in line with the axis of the copper tube body The included angle β is 25°; the tooth top heights of tooth rib A, tooth rib B, tooth rib a, and tooth rib b respectively decrease from the first line to the last line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com