Bract-discharging and corn-recycling device of corn husker

A technology of peeling machine and corn kernels, applied in threshing equipment, agricultural machinery and implements, agriculture, etc., can solve the problems of no corn kernel recovery device, no control panel, and falling on the flat plate, etc., to achieve simple structure, High safety factor, realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

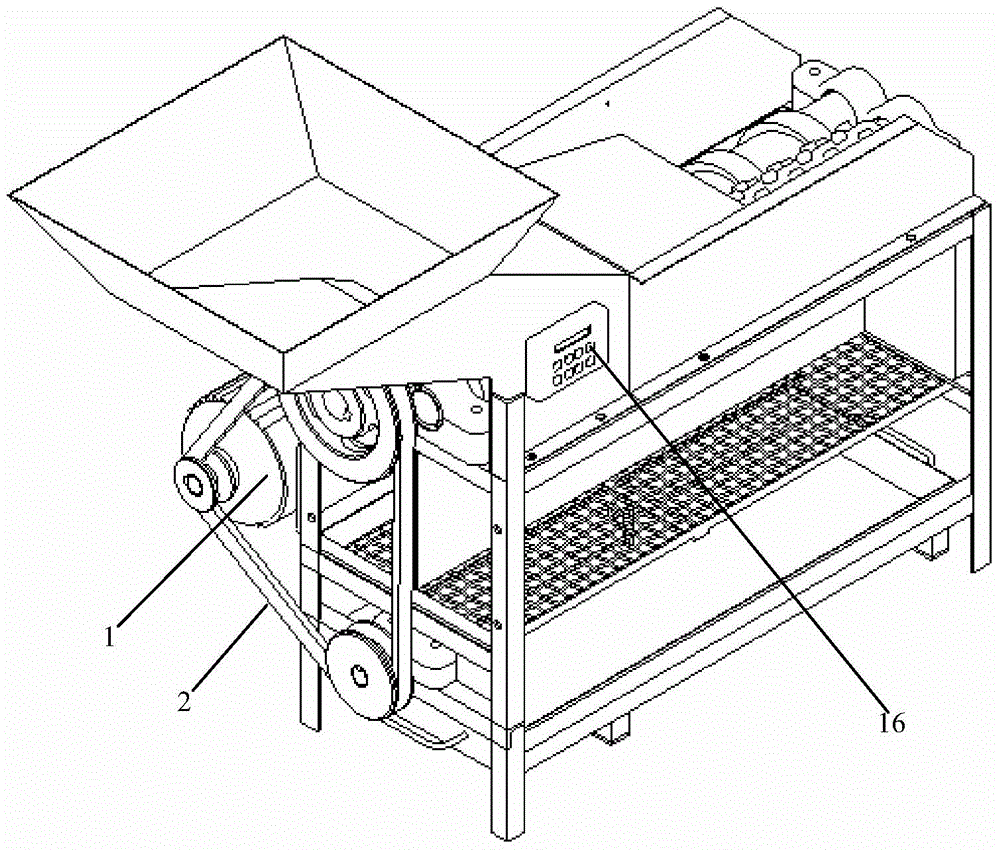

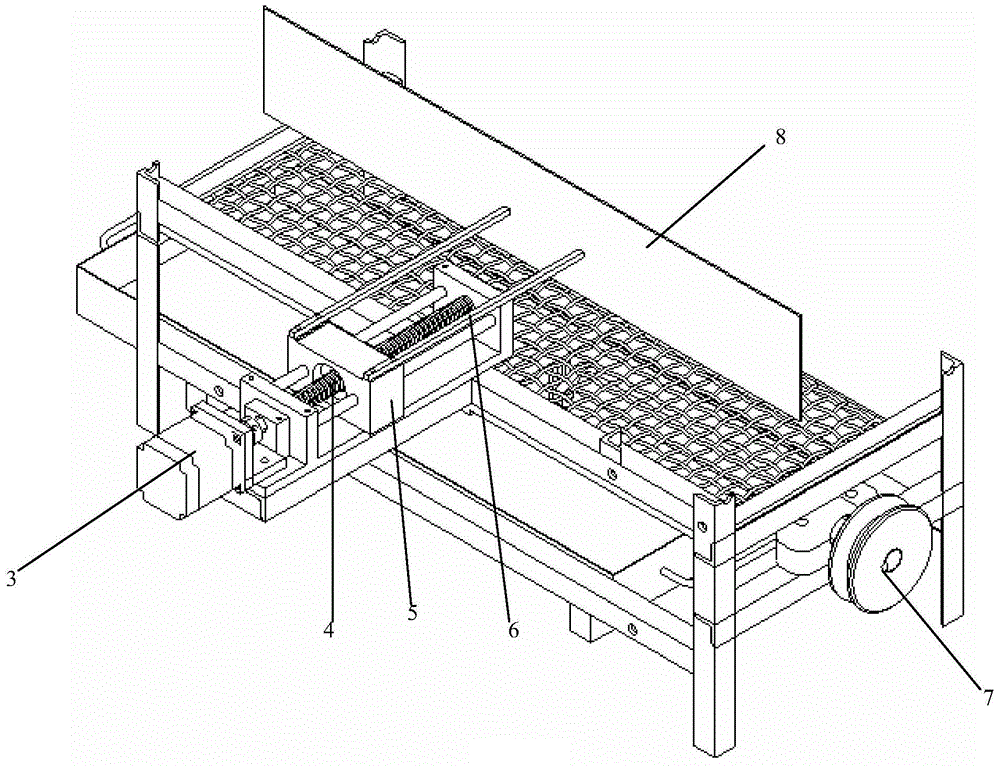

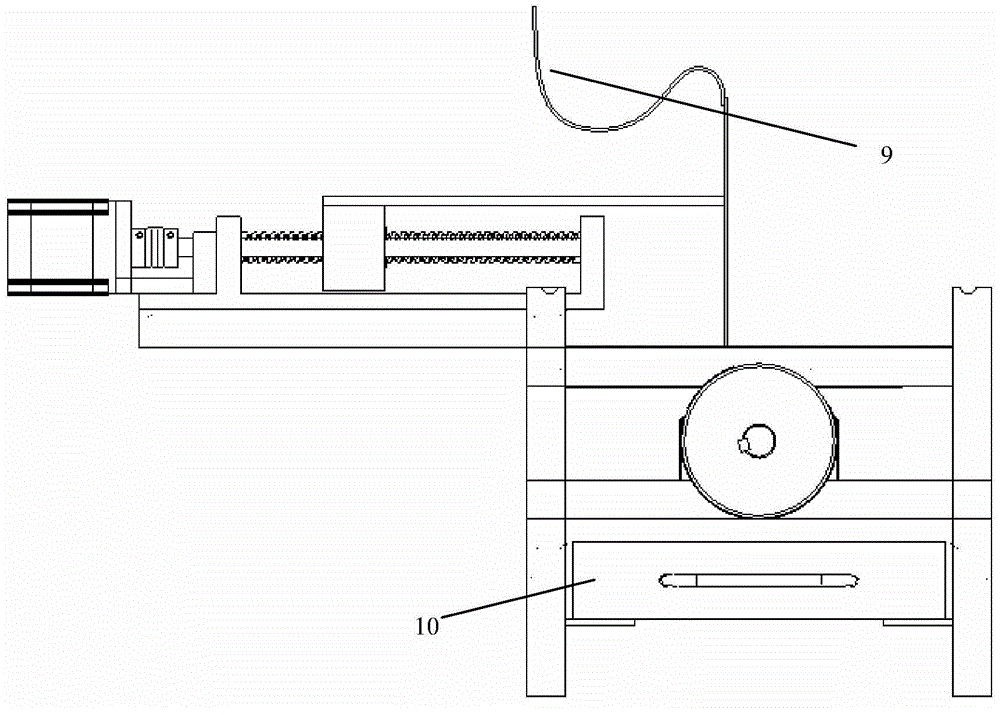

[0023] Such as figure 1 — Figure 5 Shown, a kind of corn peeling machine discharges bracts and reclaims corn grain device, comprises screening device, is positioned at the pushing device above screening device and the control device that contains single-chip microcomputer, it is characterized in that described screening device comprises vibrating pulley 7, Recovery box 10, steel wire mesh 11, vibration shaft 12; the vibration pulley 7 is driven to rotate through the motor 1, one end of the vibration shaft 12 is connected with the vibration pulley 7, and the other end is connected with the cam 13, and the cam 13 is equipped with a cylindrical toggle Shaft 14, the toggle shaft 14 is located in the guide groove 15, the notch of the guide groove 15 is arranged in the vertical direction, and the guide groove 15 is fixedly connected with the steel wire mesh 11 arranged horizontally; the vibration shaft 12 rotates, thereby making the toggle The shaft 14 rotates in the guide groove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com