Raymond mill

A Raymond mill and stand technology, which is applied in grain processing and other directions, can solve the problems of unsuitable production of ultra-fine powder, large powder particle size, energy waste, etc., and achieve less powder falling back and grinding and pulverizing efficiency. High, yield-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

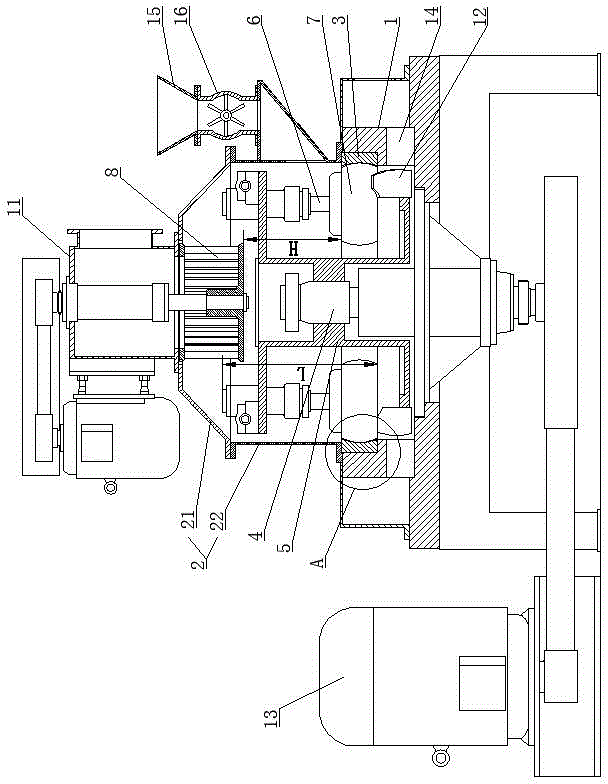

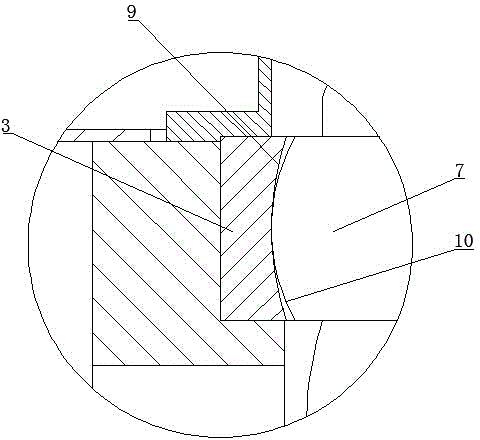

[0015] Such as figure 1 As shown, the Raymond mill includes a machine base 1, a cylinder 2 is connected to the top surface of the machine base 1, a grinding ring 3 is installed in the machine base 1, and a main shaft extending into the cylinder 2 is connected to the machine base 1 for rotation. 4. The main shaft 4 is driven by the main motor 13. The main shaft 4 is connected with a plum blossom frame 5. The top of the plum blossom frame 5 is hinged with multiple sets of grinding roller assemblies. The grinding roller assembly includes a grinding roller hinged on the plum blossom frame 5. The shaft 6 and the grinding roller 7 mounted on the grinding roller shaft 6; the bottom of the plum frame 5 is connected with a plurality of blades 12 for scooping up materials, and the number of blades 12 is the same as that of the grinding roller assembly. The base 1 is provided with an air inlet 14 for air intake into the machine, and the cylinder body 2 is provided with a feeding hopper 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com