Cutting machine for aluminum profile

A technology for aluminum profiles and cutting machines, which is applied in the direction of metal sawing equipment, sawing machine devices, metal processing equipment, etc., and can solve problems such as the inability to solve the support function of aluminum profiles and the problem of dimensional positioning of aluminum profiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

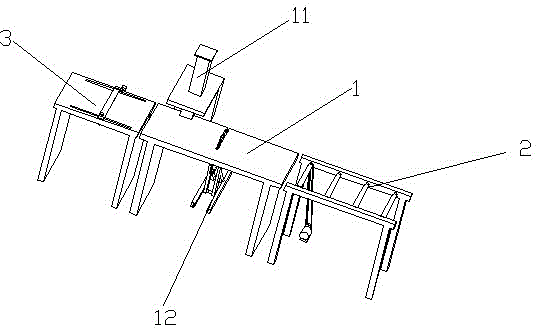

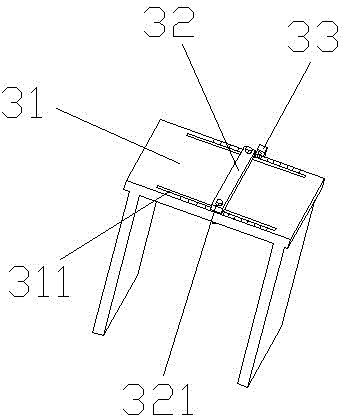

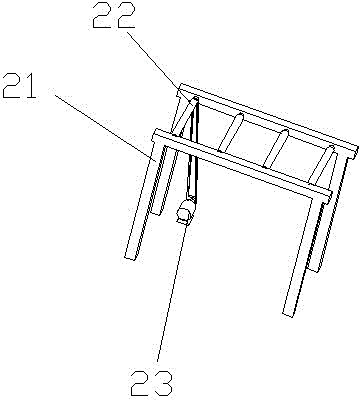

[0022] Example 1, such as Figure 1-4 , a cutting machine for aluminum profiles, including a frame and a workbench 1 arranged on the frame, an aluminum pressing mechanism 11 and a cutting mechanism 12 are arranged on the workbench, and one side of the workbench 1 is provided with a The support mechanism 2, the other side of the workbench is provided with a positioning mechanism 3 for positioning aluminum profiles, the support mechanism 2 includes two parallel support frames 21, a roller 22 arranged between the support frames and a motor 23 for driving the roller 22, The positioning mechanism 3 comprises a positioning platform 31, a positioning block 32 arranged on the positioning platform and an induction device 33 arranged on the positioning block. Fastening components 321 that match the positioning groove 311 are respectively provided on both sides, and a scale is provided on the positioning groove 311. The upper end of the roller 22 is tangent to the plane where the positio...

Embodiment 2

[0023] Embodiment 2, as embodiment 1 Figure 1-4 , a cutting machine for aluminum profiles. The aluminum profile is conveyed through the support mechanism 2. The workbench 1 is compressed by the pressing mechanism 11 in the first step, and then the cutting mechanism 12 cuts a small piece, and the aluminum profile head is cut. Then loosen Open and enter the positioning mechanism 3, select the appropriate size, so that each aluminum profile is close to the positioning block 32, and at the same time, the induction device 33 controls the motor 23 to cut off the power, so that the cutting machine is more energy-saving, and then cut by pressing the pressing mechanism 11, So cycle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com