High-altitude hoisting and quick release device for generator

A technology for generators and conveyor belts, applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of increasing labor intensity, reducing work efficiency, and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

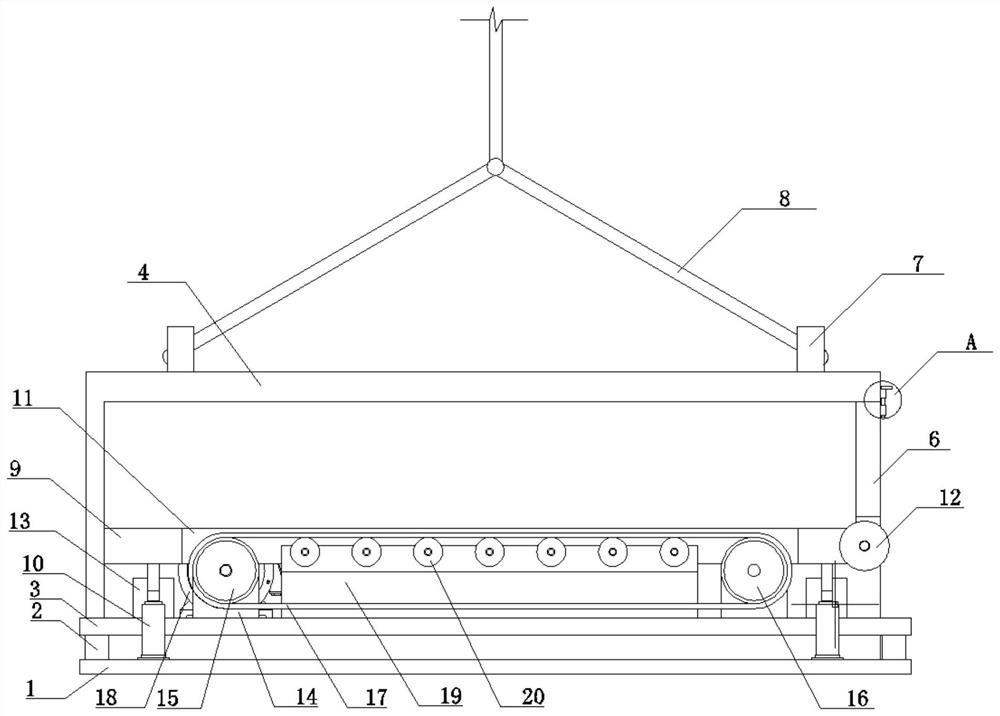

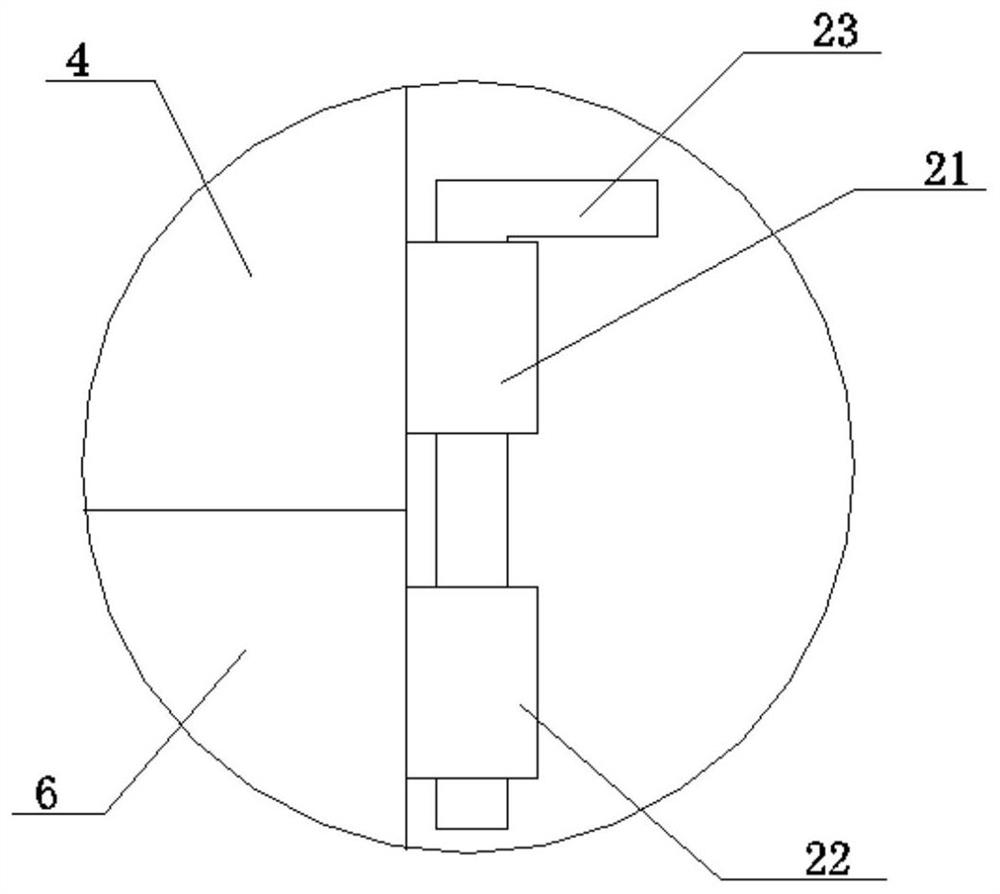

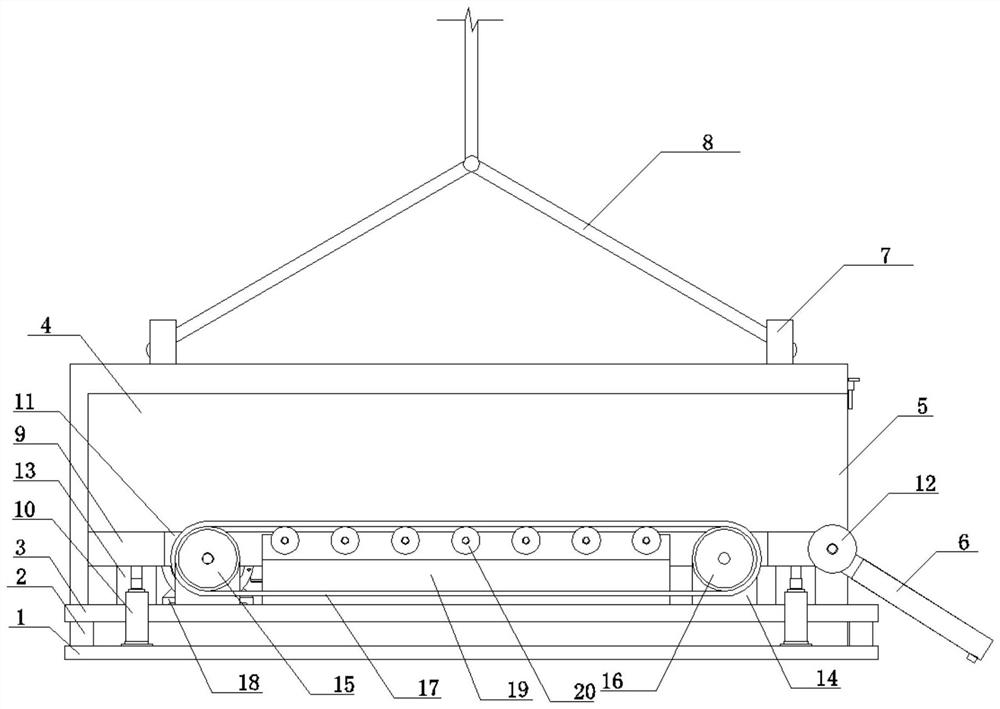

[0030] The high-altitude hoisting and quick release device for generators includes a base 1, the upper end of the base 1 is fixedly connected with a fixed seat 3 through a bracket 2, the upper end of the fixed seat 3 is provided with a supporting component and a transmission component, and the upper surface of the base 1 is fixedly connected with a frame body 4 One end of the frame body 4 is provided with an opening 5, and the opening 5 is rotatably connected with a baffle plate 6, and the upper end of the frame body 4 is fixedly connected with four suspension rings 7, and the suspension ring 7 is connected with a drag cable 8; one part of the frame body 4 The side is fixedly connected with a fixed sleeve 21, and the top of the outer wall of the baffle plate 6 is fixedly connected with a fixed sleeve 22, and a fixed pin 23 runs through between the fixed sleeve 1 21 and the fixed sleeve 22; To the fixing effect, when the frame body 4 is lifted by the drag cable 8, the frame body...

specific Embodiment approach

[0035] 1. Pull the fixing pin 23 out of the fixing sleeve 22, put down the baffle plate 6, and drive the hydraulic cylinder 10 to drive the support seat 9 to rise above the top of the conveyor belt 17;

[0036] 2. Push the generator onto the support base 9 through the baffle 6, close the baffle 6, and put down the fixing pin 23 to fix the baffle 6;

[0037] 3. Connect the cable 8 to the suspension ring 7, and drive the cable 8 to lift the frame 4 through the crane to lift the generator;

[0038] 4. After lifting the generator to the designated position, pull out the fixed pin 23, put down the baffle plate 6, start the motor 18, the motor 18 drives the driving pulley 15 to rotate, and the driving pulley 15 drives the driven pulley 16 through the conveyor belt 17, The generator is transported to the opening 5 through the conveyor belt 17, the generator enters above the baffle 6 through the guide roller 12, and slides down to the transportation place through the baffle 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com