Spiral conveying assembly and solid-liquid separation equipment

A technology of screw conveying and components, applied in the field of solid-liquid separation equipment, can solve the problems of low efficiency of solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

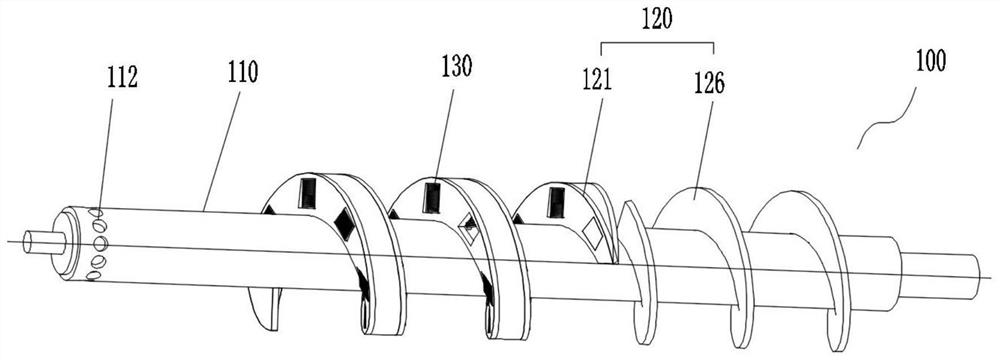

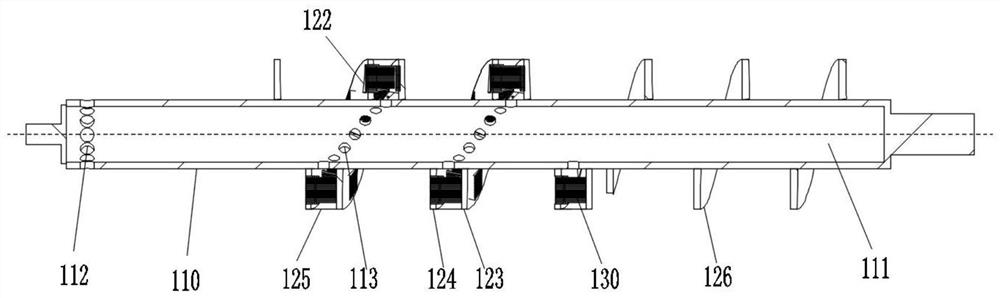

[0044] like figure 1 , figure 2 and image 3 As shown, a screw conveying assembly 100 provided in this embodiment includes a rotating shaft 110 and a screw blade assembly 120 , the screw blade assembly 120 is arranged on the rotating shaft 110 , and the rotating shaft 110 drives the screw blade assembly 120 to rotate.

[0045] Wherein, the rotating shaft 110 adopts a hollow shaft, and the interior of the rotating shaft 110 is provided with a water collection chamber 111 for collecting the liquid produced by the material. the liquid in the water cavity 111;

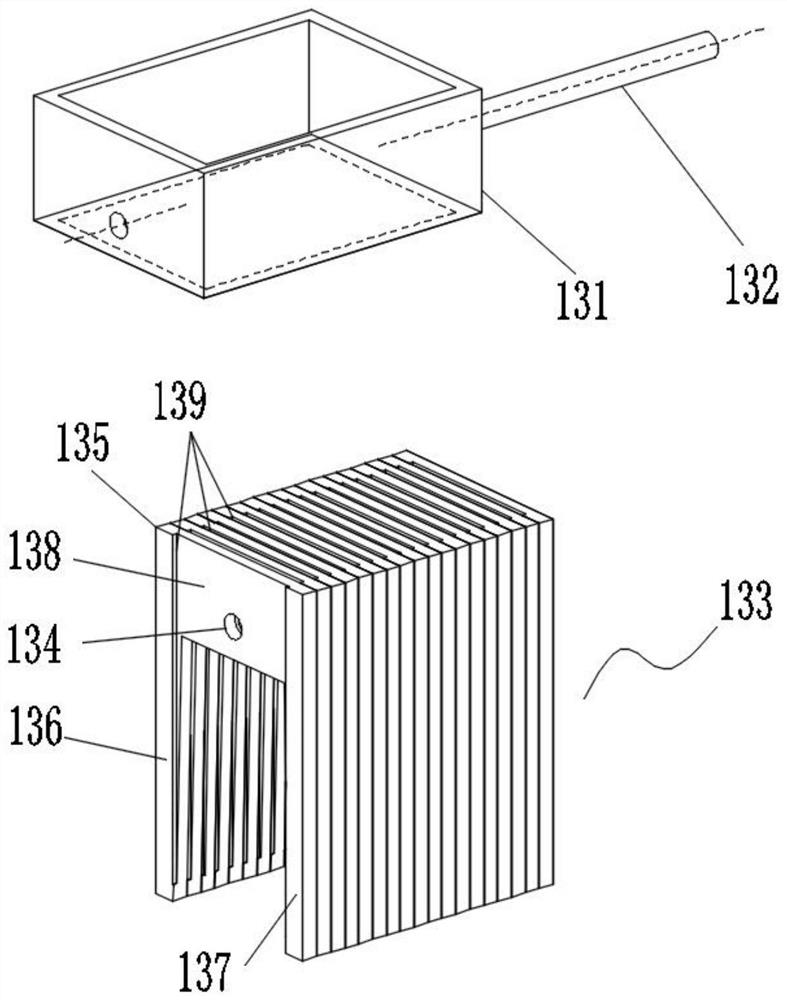

[0046] The spiral blade assembly 120 includes a hollow blade 121. The hollow blade 121 is provided with a plurality of installation holes 122 along the material conveying direction. The installation holes 122 communicate with the inner cavity of the hollow blade 121. The rotating shaft 110 is provided with a plurality of water holes 113 for communication. The inner cavity and the water collecting cavity 111, a pluralit...

Embodiment 2

[0061] like Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, a solid-liquid separation device provided in this embodiment includes a housing 200, a water collector 300, a separation screen 400, a fixing frame 500, and the screw conveying assembly 100 in the first embodiment above;

[0062] It should be noted that, since the structure and working principle of the screw conveying assembly 100 have been described in the first embodiment, please refer to the technical solution of the first embodiment for the screw conveying assembly 100 involved in this embodiment.

[0063] In this embodiment, the housing 200 is provided with a material conveying cavity along the axial direction, and the material conveying cavity is divided into a connected feeding section 210 and a feeding section 220 along the material conveying direction;

[0064] The screw conveying assembly 100 is arranged in the material conveying cavity, the separating screen 400 is arranged in the conveying sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com