Self-refrigerating type cooling device for printing and dyeing work of textile industry

A textile industry and cooling device technology, which is applied in the processing of textile materials, equipment configuration, textiles and papermaking, heating/cooling fabrics, etc., can solve the problems of effect impact, high cooling cost, poor cooling effect, etc., and achieve easy management and extended stay Time, the effect of improving controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

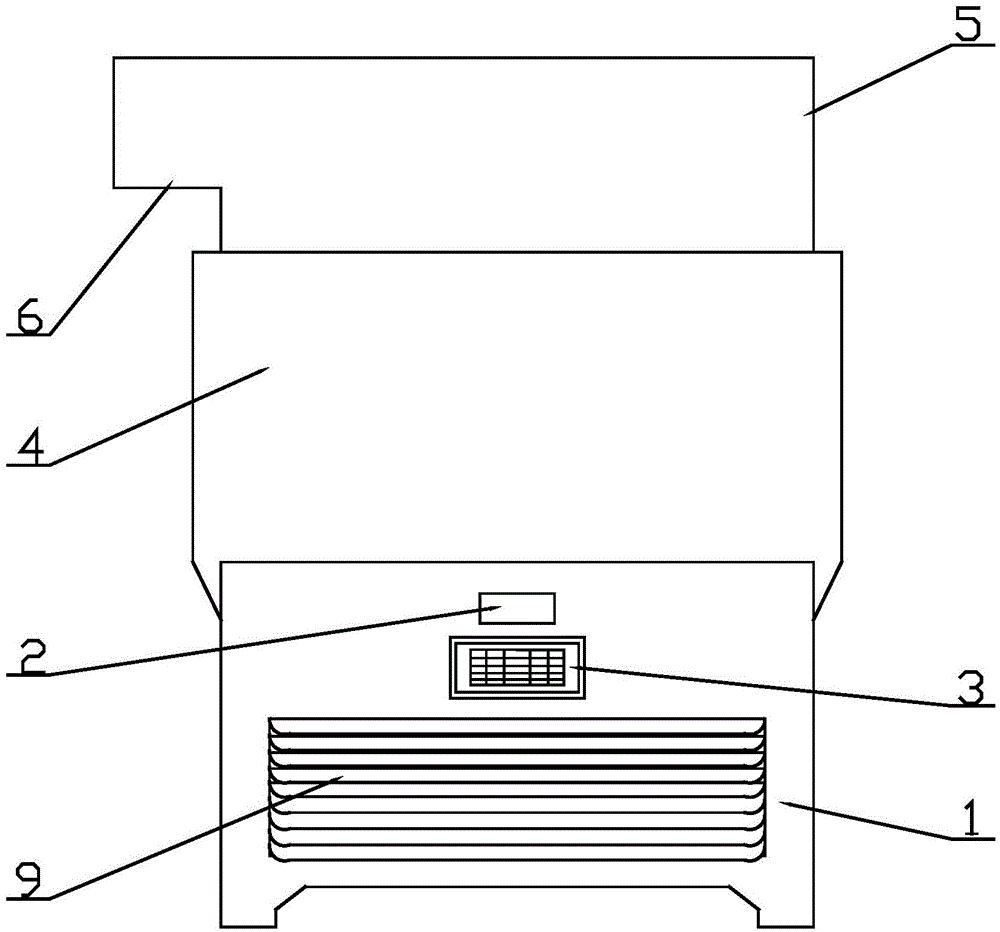

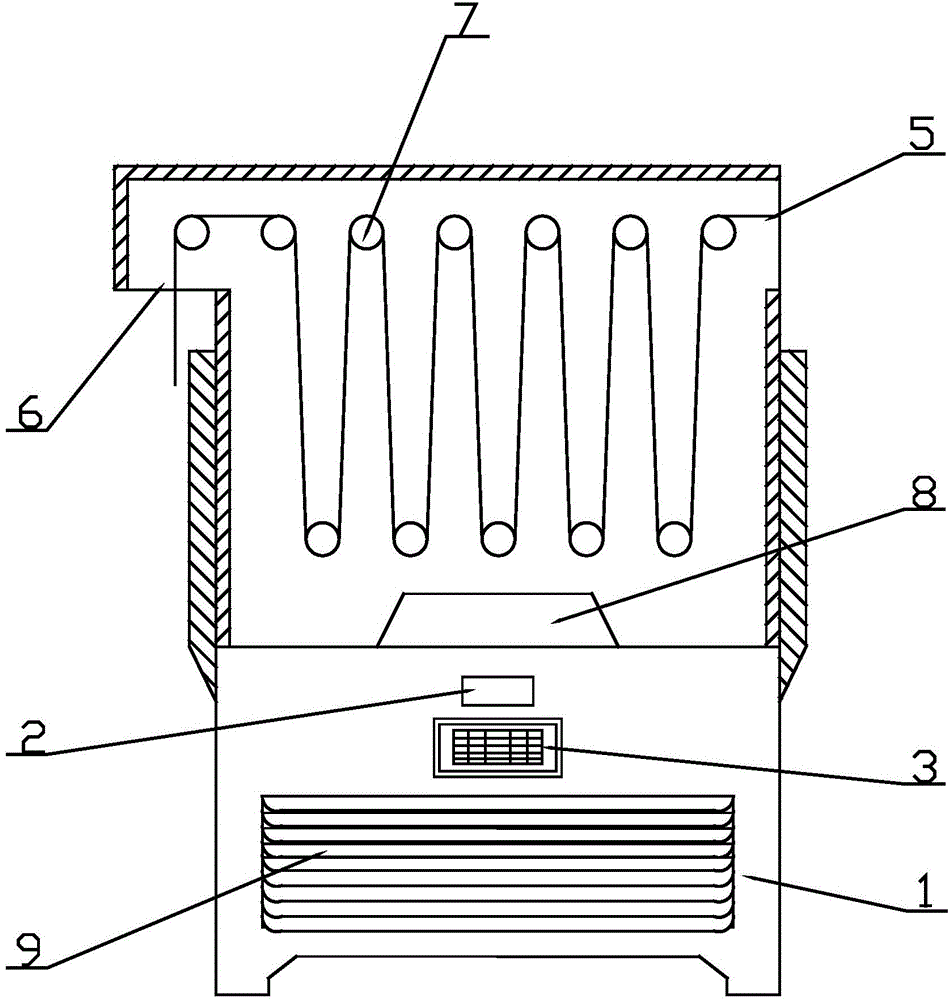

[0016] A self-refrigerated cooling device for printing and dyeing in the textile industry, comprising a refrigeration chamber 1, a thermometer 2, a control panel 3, a working chamber 4, an inlet 5, an outlet 6, a roller set 7, an air-conditioning nozzle 8, and cooling holes 9.

[0017] like figure 1 As shown, the working compartment 4 is arranged on the upper part of the refrigeration compartment 1, and the cooling compartment 1 is provided with cooling holes 9 in the lower part of one side, and a thermometer 2 and a control panel 3 are arranged in the upper part. The refrigeration compartment 1 is specifically a thermoelectric cooling device.

[0018] like figure 2 As shown, the working chamber 4 is provided with an outlet 6 on one side and an inlet 5 on the other side. In the working chamber 4, a roller set 7 is arranged on the upper part, and a cold air nozzle 8 is arranged on the lower part. The cold air One end of the spray head 8 penetrates through the thin wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com