Spray-packing combined direct evaporative cooler

An evaporative cooler and composite technology, applied in natural cooling systems, energy-saving heating/cooling, heating methods, etc., can solve problems such as cost increase, high water quality requirements, and easy to be blocked

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

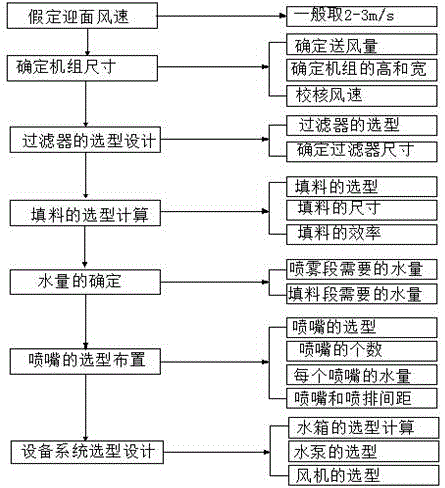

[0028] Such as figure 1 As shown, the design process of the spray-packing composite direct evaporative cooler of the present invention is as follows: determine the size of the direct evaporative cooler under the assumed head-on wind speed, and check the wind speed; select the filter material of the coarse filter section, and determine the filter material The size of the device; select and calculate the filler in the packing section, and determine the total water consumption of the direct evaporative cooler by the amount of water required in the spray section and the water required in the packing section; select and arrange the nozzles in the spray section; Calculate the size of the tank and size the pump and fan.

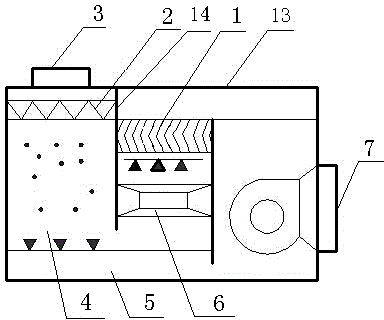

[0029] Such as figure 2 As shown, the spray-packing composite direct evaporative cooler includes a housing 13, an air inlet 3 and an air outlet 7 arranged outside the housing 13, a filter device arranged in the housing 13, a spray water tank 5, and a packing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com