A virtual pre-assembly algorithm based on vb plug-in and its application

A pre-assembled and plug-in technology, applied in the research and development and application of virtual reality technology, can solve problems such as low degree of automation, difficulty in achieving project-level applications, lack of operability-related processes and guidance documents, etc., to improve accuracy and efficiency , low cost, and optimized construction schedule

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment example the present invention is further described:

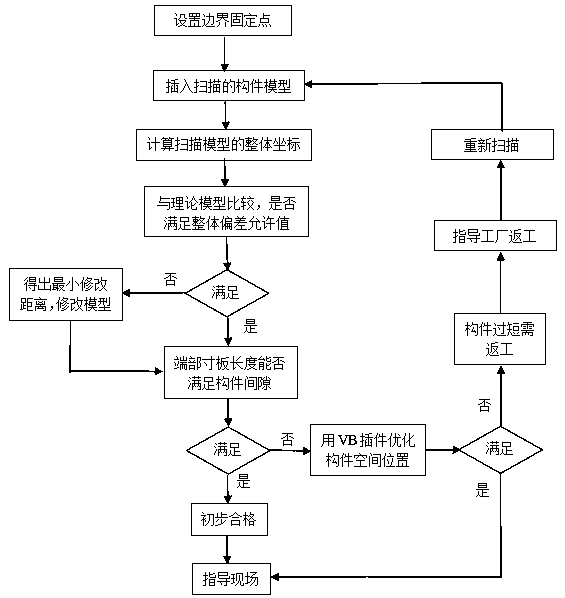

[0029] A virtual pre-assembly algorithm based on a VB plug-in, including the following core command algorithm steps:

[0030] Step 1, determine the axis: automatically determine the respective centers of each point obtained by the total station through an algorithm, and form an axis;

[0031] Step 2, AL command initial positioning: Call the AL command of CAD itself to align the components to be assembled from any position along the central axis to the target central axis;

[0032] Step 3: Rotate fine-tuning around the central axis: By rotating around the central axis, various rotation angles are obtained, and the minimum total distance is taken to minimize the average distance of the feature point pairs of each component;

[0033] Step 4, Rotation fine-tuning: Around the center point M, the assembled components are fine-tuned, so that the distance between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com