electric pump

A technology for electric pumps and motors, applied to electric components, pumps, brakes, etc., can solve the problems of wiring harnesses and connectors, and achieve the effect of ensuring installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, an electric pump according to an embodiment of the present invention will be described with reference to the drawings.

[0050]

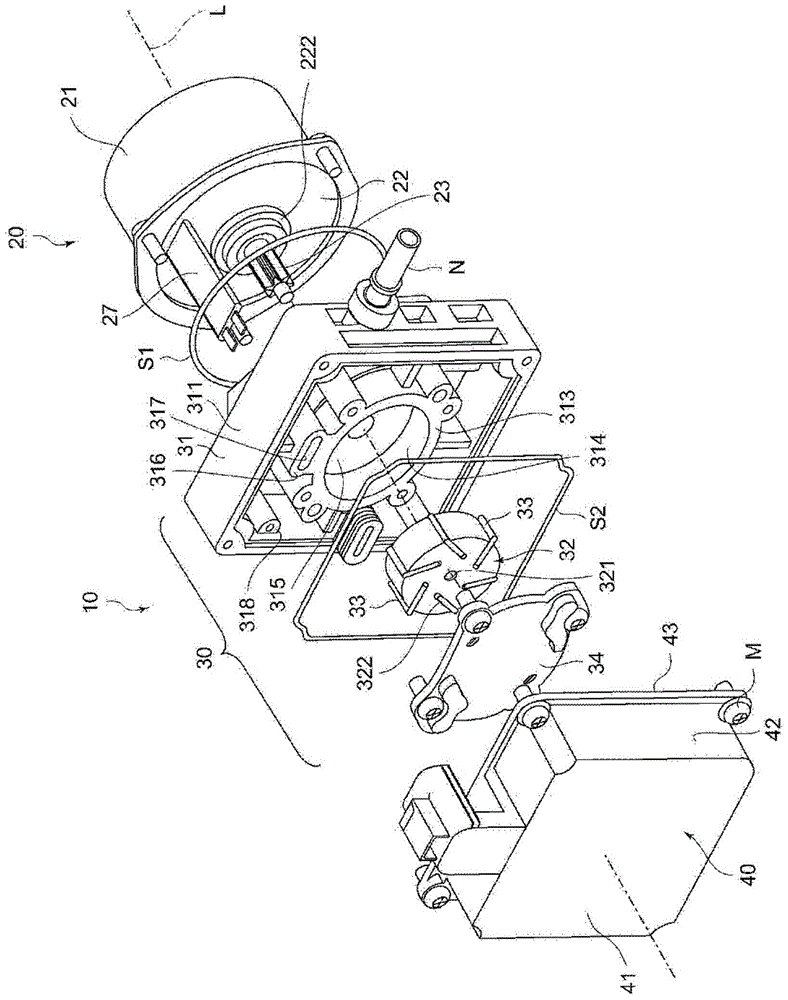

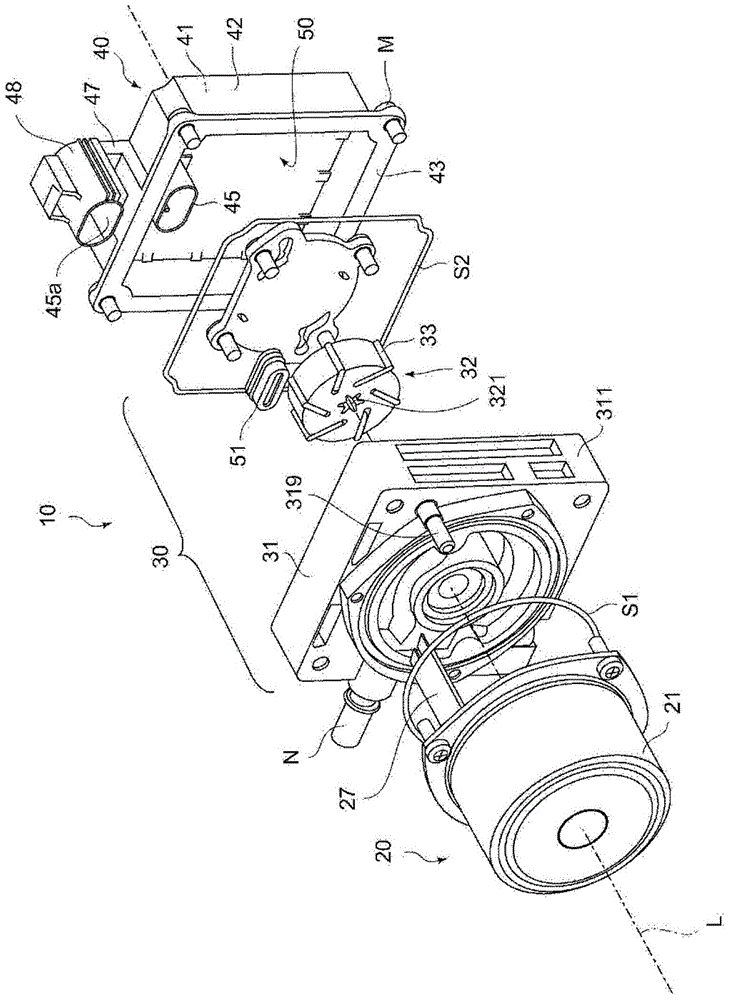

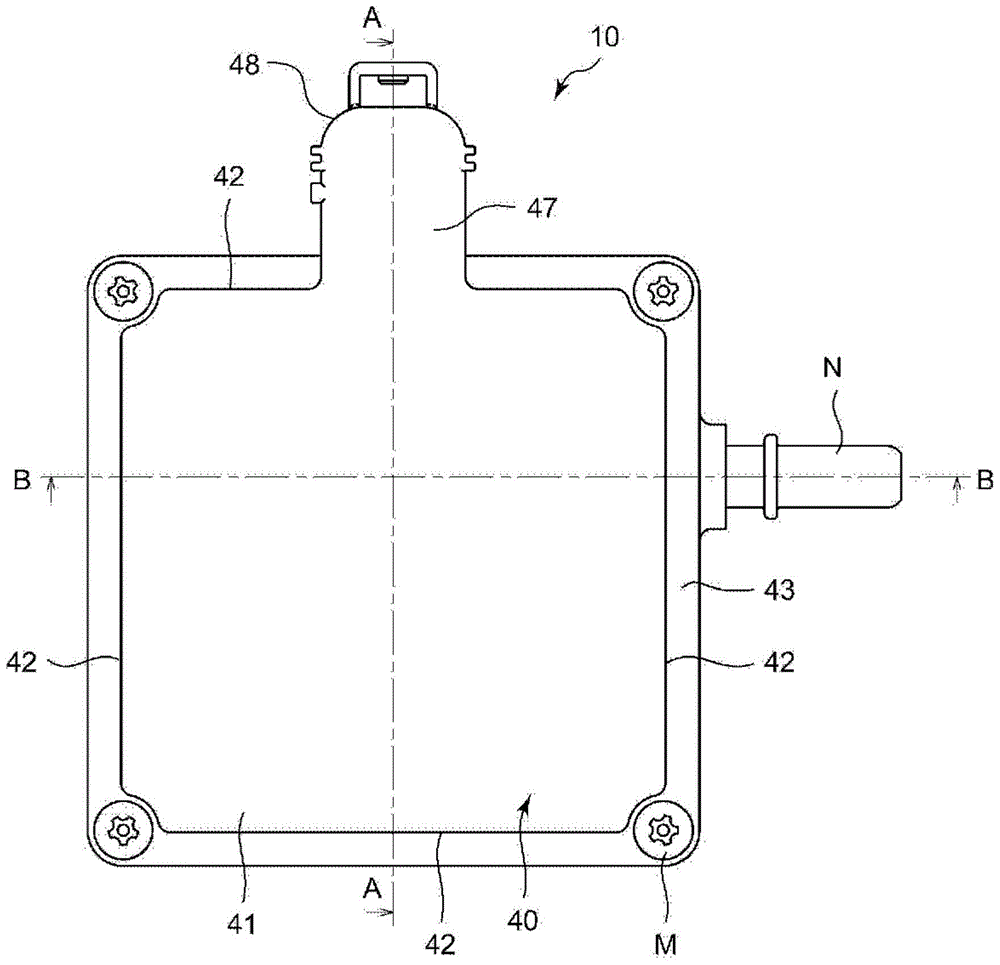

[0051] figure 1 It is an exploded perspective view showing the structure of the electric pump 10 viewed from the pump cover 40 side, figure 2 It is an exploded perspective view showing the configuration of the electric pump 10 viewed from the motor unit 20 side. in addition, image 3 It is a front view showing the configuration of the electric pump 10 viewed from the pump cover 40 side. Such as Figure 1 ~ Figure 3 As shown, the main constituent elements of the electric pump 10 include a motor portion 20 , a vane pump portion 30 , and a pump cover 40 .

[0052] Figure 4 It means viewing from the side along the image 3 A cross-sectional view of the state in which the electric pump 10 is cut along the line A-A in FIG. in addition, Figure 5 It means viewing from the side along the image 3 A cross-sectional view of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com