Quick planting technology and device based on zero shift

A zero-displacement, speed-increasing device technology, applied in the direction of planting methods, applications, excavation/covering trenches, etc., can solve the problems of large operation resistance, low operation efficiency, and high labor intensity, so as to reduce the time of drilling holes and improve Work efficiency and the effect of increasing work speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

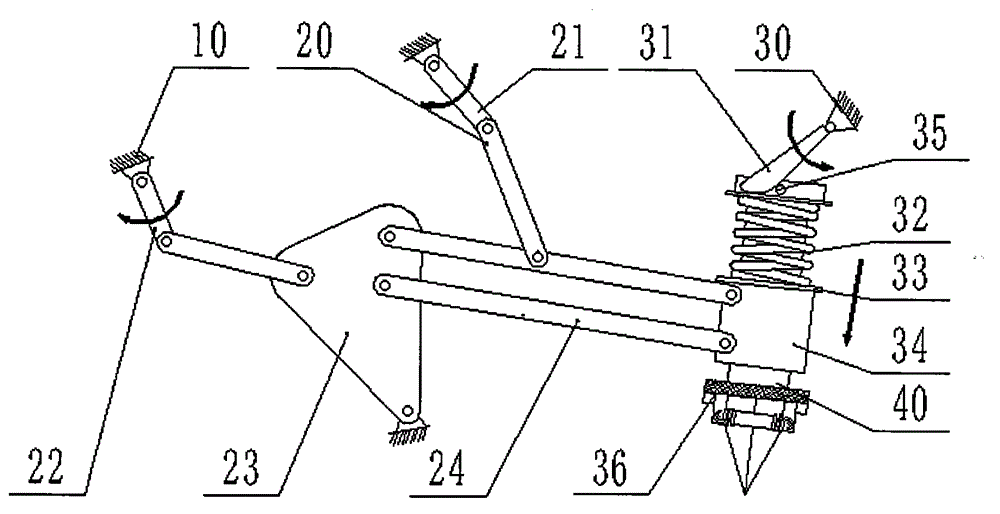

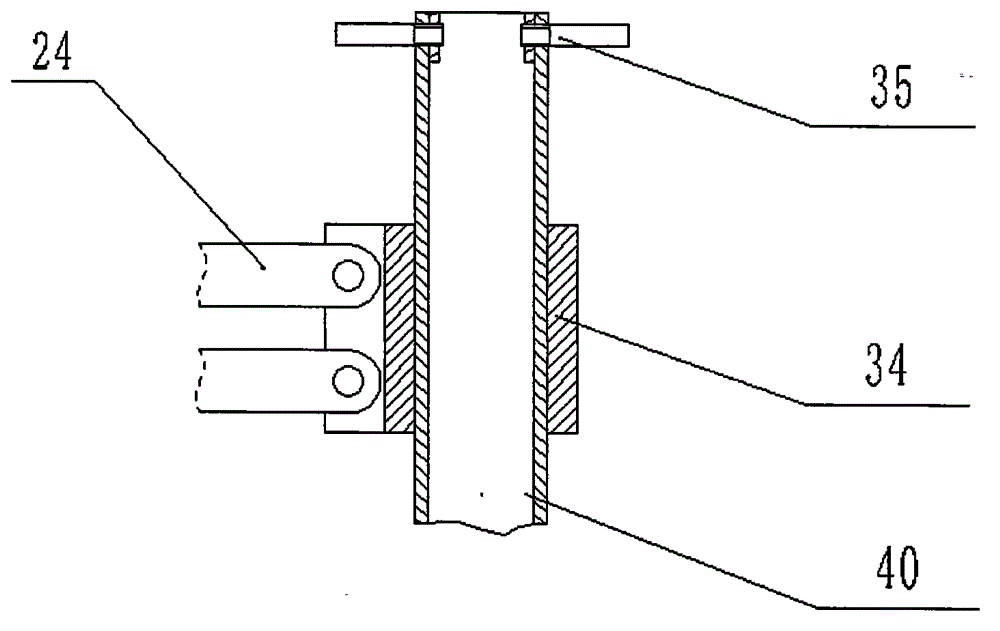

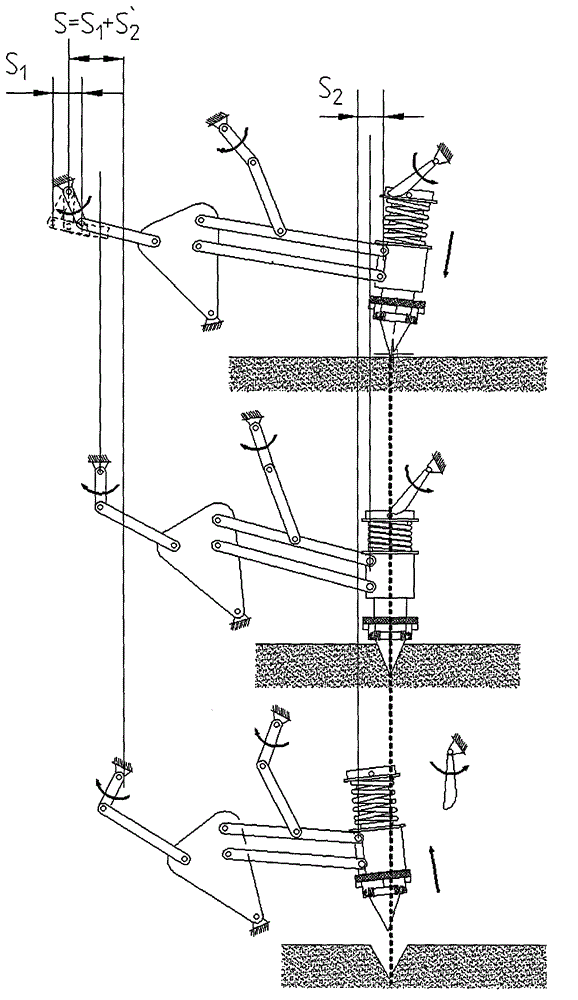

[0022] figure 1 , 2, 4 and 5, 10 is the frame, 20 is the double crank cradle linkage mechanism, 21 is crank 1, 22 is crank 2, 23 is the cradle, 24 is the parallel rod mechanism, 30 is the speed increasing device, 31 is a rotating body, and 32 is a spring, and 33 is a baffle plate, and 34 is an axle sleeve, and 35 is a bearing pin, and 36 is a spacer spring washer, and 40 is a hole punching body.

[0023] The double crank cradle link mechanism (20) drives the parallel rod mechanism (24) to move up and down through the crank 1 (21) on the one hand, and then drives the shaft sleeve (34) and the hole punching body (40) to move up and down; 2 (22) drives the cradle (23) to swing, and then drives the axle sleeve (34) and the punching hole body (40) to swing left and right, realizing the zero displacement punching operation of the punching ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com