Marking method for defective products of radio frequency tags

A technology of wireless radio frequency and marking method, which is applied in image data processing, printing, instruments, etc. It can solve problems such as low production efficiency, weak labels of outflowing defective products, and slow operation speed, so as to improve quality, maintain easy identification, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

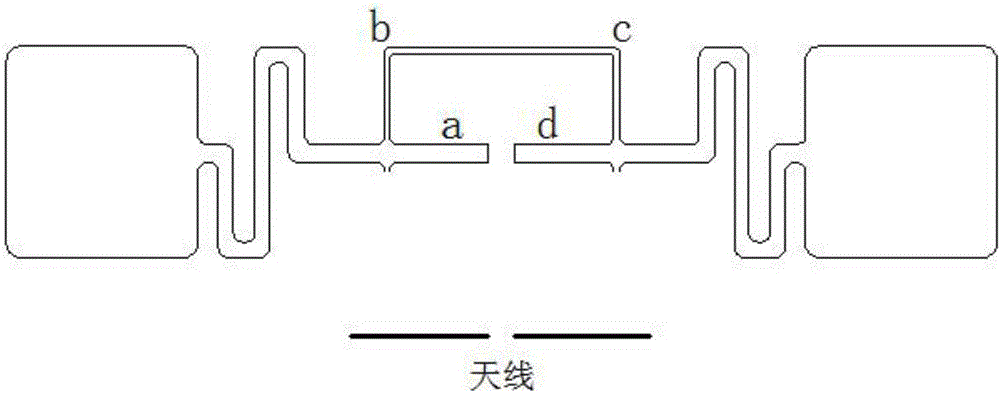

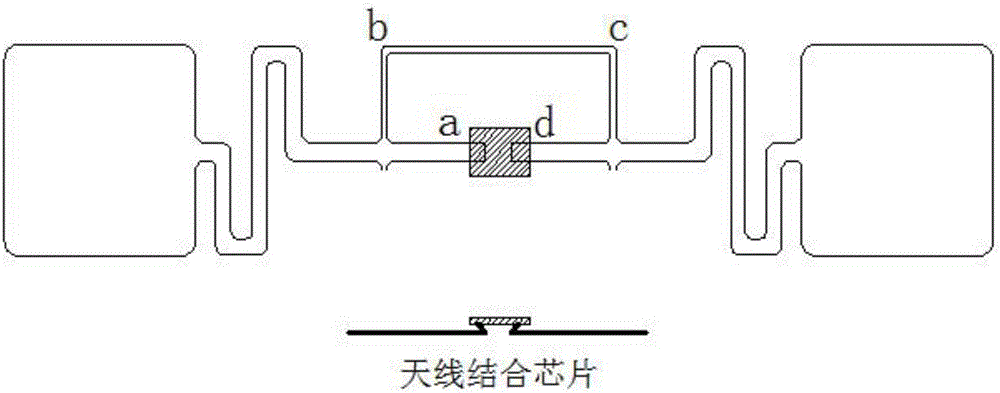

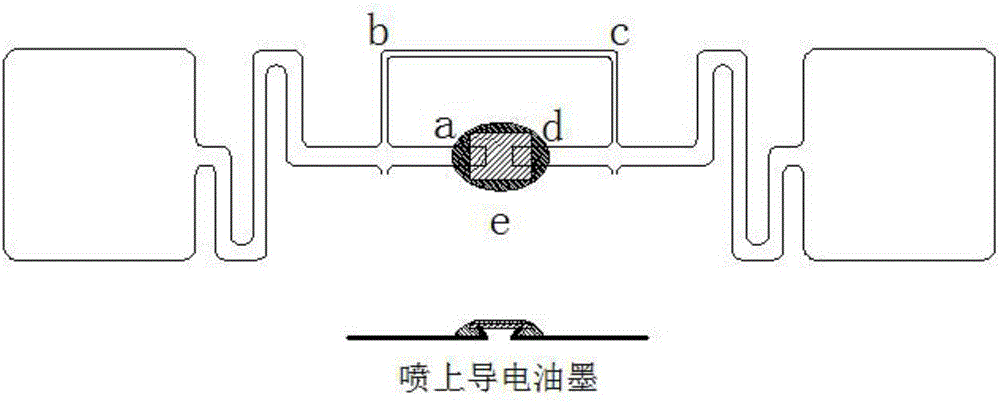

[0022] Such as Figure 1-3 Shown, a kind of marking method for radio frequency label defective product is characterized in that, comprises the following operation steps:

[0023] (1) Preliminary detection of electronic radio frequency tags;

[0024] (2) Screen out weak standard or unqualified products through the detection of step (1);

[0025] (3) Perform conductive ink spray printing at the core position of the weak standard product or unqualified product in step (2) to form aed short circuit path;

[0026] (4) Use conductive materials to greatly reduce the resistance between the two contacts of the chip or the two contacts on the antenna corresponding to the chip, making the weak-label RFID a defective product;

[0027] (5) In the next step of the preparation process, it can be judged that the RFID is a defective product through electrical test identification, personn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com