High-efficiency porous silencing plate punching die

A sound-absorbing board, high-efficiency technology, used in perforating tools, manufacturing tools, metal processing equipment, etc., can solve problems such as affecting product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

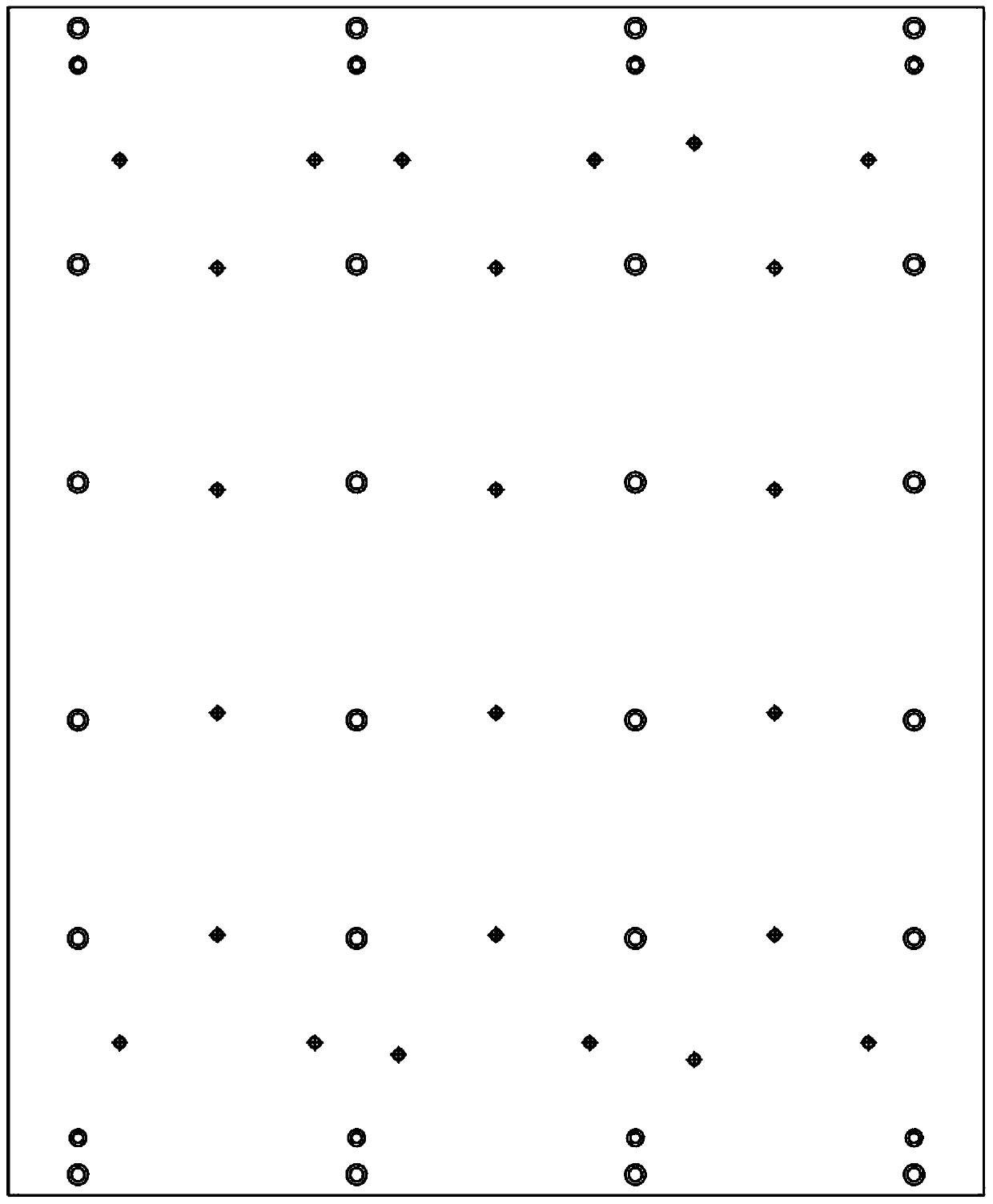

[0044] Such as Figure 1-19 As shown, a high-efficiency punching 51 mold for porous sound-absorbing panels provided by the present invention includes an upper mold base 20, an upper backing plate 21, an upper splint 30, a stopper plate 40, a stripper plate 50, a lower mold frame 60, Multi-group input block 65, lower backing plate 70, lower mold base 80;

[0045] The movable pad of the upper backing plate 21 is arranged between the upper mold base 20 and the upper splin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com