New nickel ore loading and unloading operation method

A new method, the technology of nickel ore, is applied in the directions of loading/unloading, storage devices, transportation and packaging, etc., which can solve the problems of sticky goods and low utilization rate of tools and tools, and achieve simple bucket filling, light weight and easy operation. The effect of speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

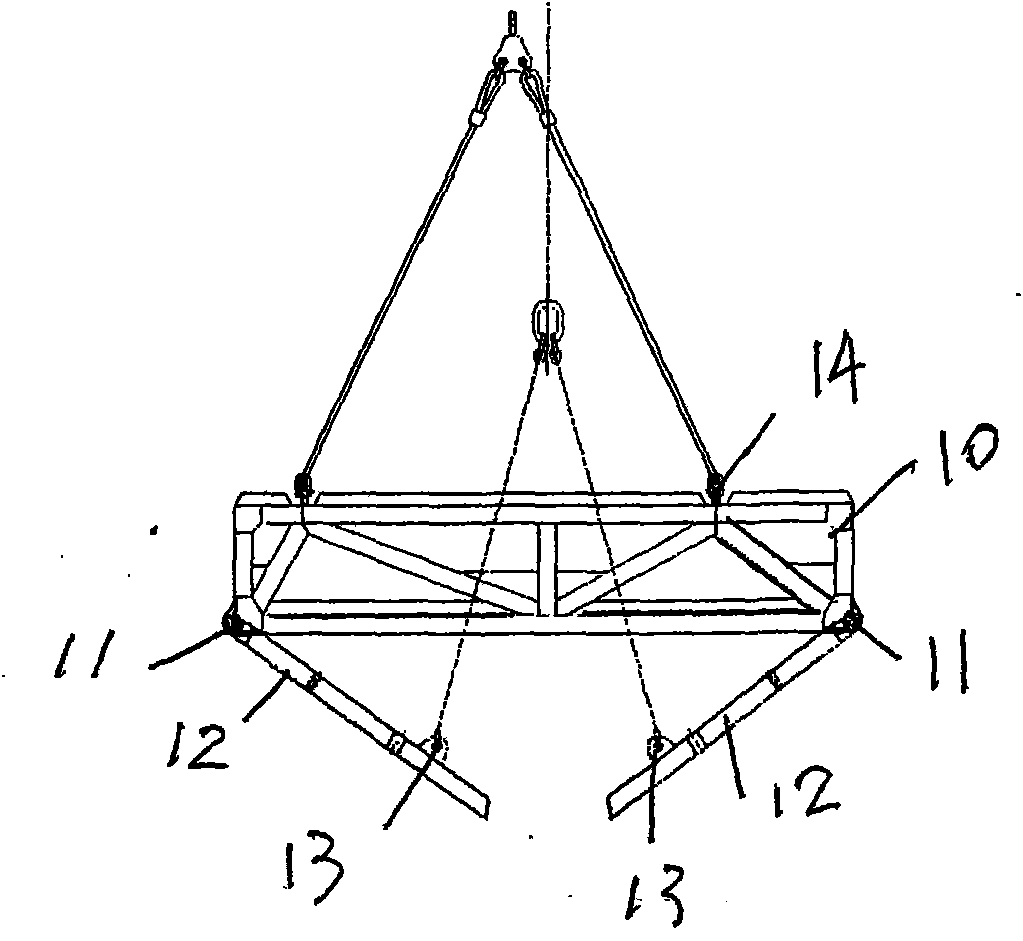

[0028] A new method of nickel ore loading and unloading operation. When loading and unloading nickel ore, first use an excavator equipped with a special bucket for nickel ore operation to load the nickel ore from the bottom of the cargo ship to a bottom-opening cargo bucket with a loading and unloading door or a nickel ore operation tray Then unload the nickel ore on the bottom-opening cargo hopper or the nickel ore operation tray to the loader on the dock, and the loader will load the nickel ore on a dump truck to the freight yard.

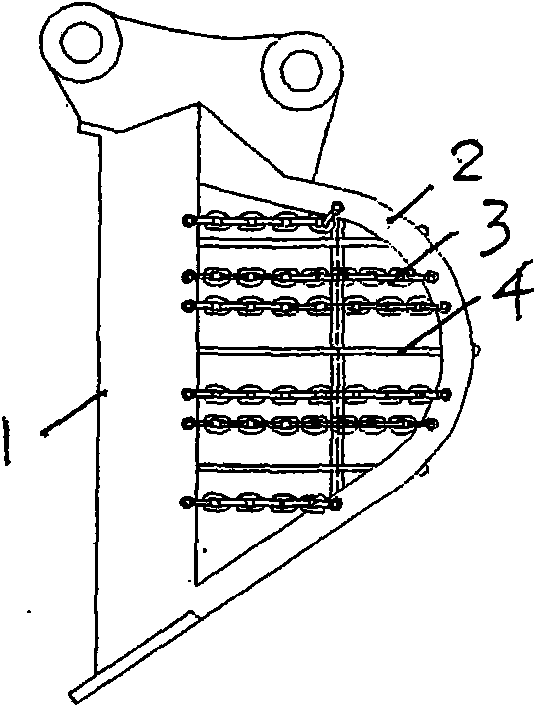

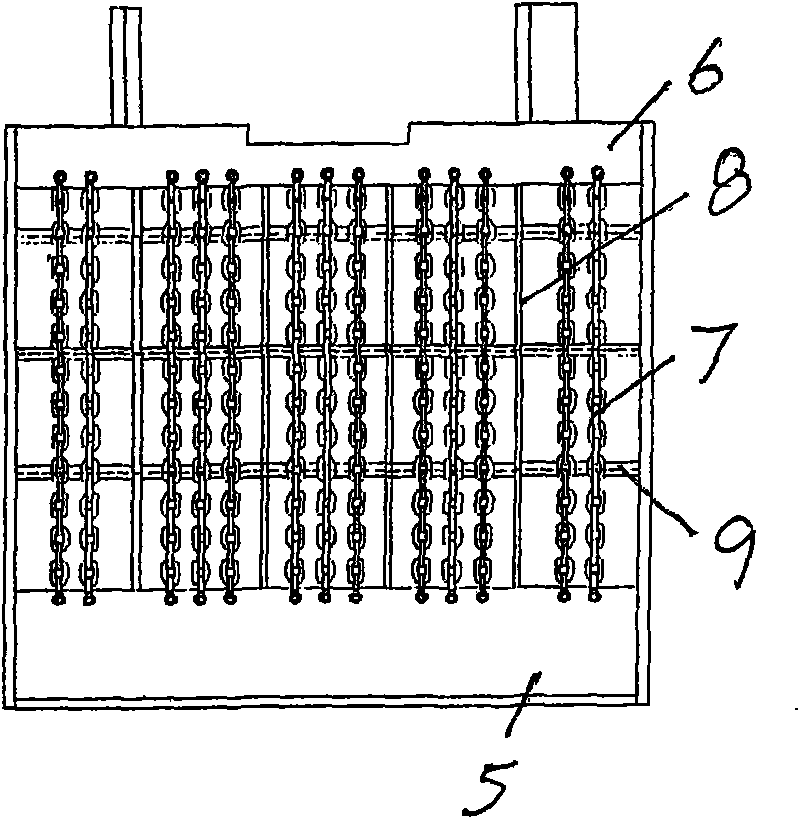

[0029] Aiming at the nickel ore operation and taking into account other bulk ore operations, a special excavator for nickel ore operation was developed. figure 1 , 2 , Bottom door cargo bucket see image 3 See with special disk for nickel ore operation Figure 4 .

[0030] The original bucket of the original excavator also faced the serious problem of cargo sticking to the bucket. After the cargo stuck to the bucket, there was no condition for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com