Continuous oil removing device for fried food

A deoiling device and fried food technology, which is applied in the direction of oil/fat baking, etc., can solve the problems of high energy consumption, inability to work continuously, and affect the taste, so as to save oil and labor, improve production efficiency, and improve greasy feeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

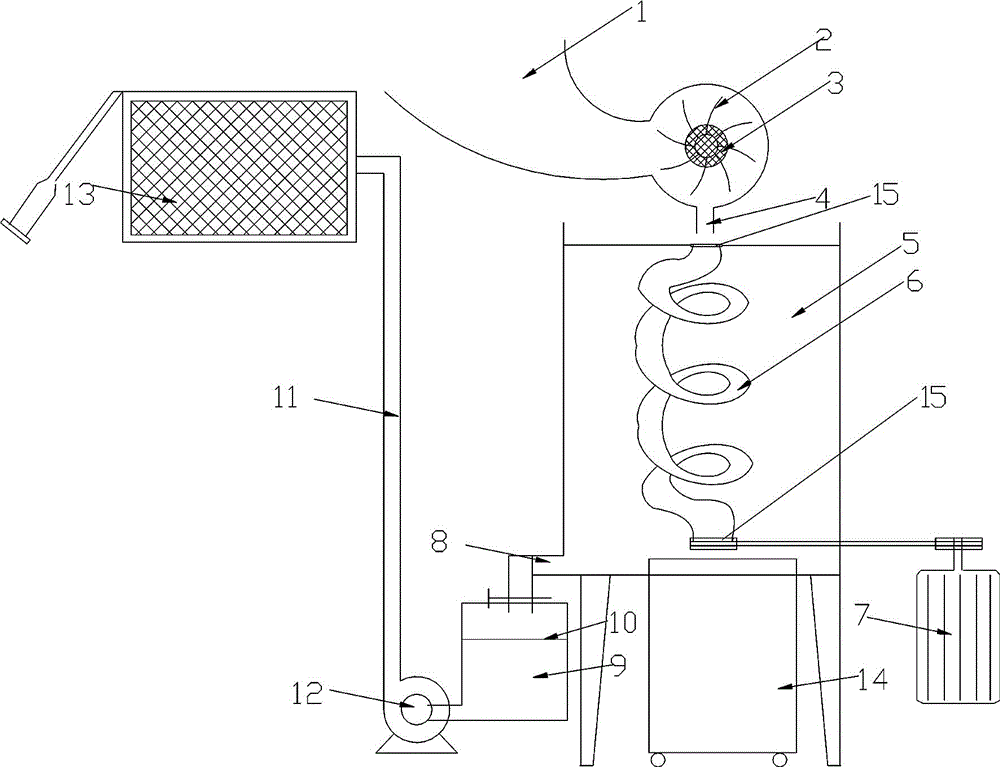

[0014] like figure 1 As shown, a continuous deoiling device for fried food includes a feed tank 1, a feeder 2 is installed in the feed tank 1, the feeder 2 is connected to a slow motor 3, and the feed tank 1 A separation box 5 is provided below, and a spiral mesh cage 6 is installed in the separation box 5. The spiral mesh cage 6 includes an upper port and a lower port. The spiral mesh cage 6 is connected to a fast motor 7, and the bottom of the separation box 5 is provided with an oil outlet. 8. An oil barrel 9 is provided below the oil outlet 8, and a filter screen 10 is arranged inside the oil barrel 9. The oil drum 9 is connected to one end of an oil delivery pipe 11 through an oil pump 12 , and the other end of the oil delivery pipe 11 is connected to a fryer 13 . A charging box 14 is arranged below the separation box 5 , and the lower port of the spiral mesh cage 6 corresponds to the charging box 14 .

[0015] The upper and lower ports of the spiral mesh cage 6 are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com