Flavored squeezed vegetable oil and preparation method thereof

A vegetable oil and oil pressing technology, which is applied in food science, edible oil/fat, fat oil/fat production, etc., can solve the problems of low attention to oil-soluble nutrients, loss of flavor and nutrition, and unbalanced intake, etc., to achieve shortening Refining process cycle, reducing phospholipid content, and inhibiting the effect of enzymatic browning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The raw material of the flavored pressed vegetable oil comprises 50 parts of rapeseed, 18 parts of sunflower seed, 2 parts of linseed and 2 parts of tomato powder.

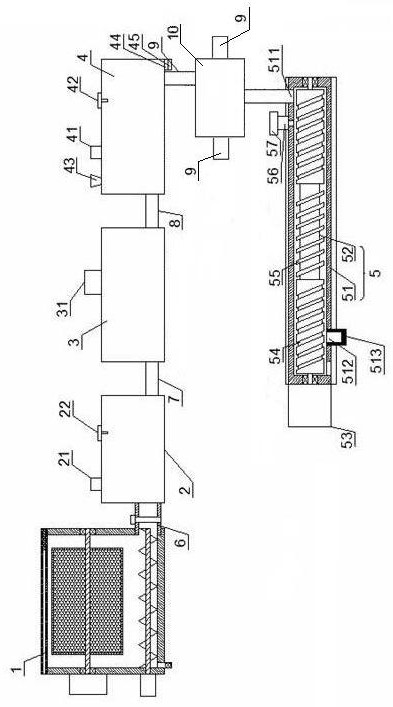

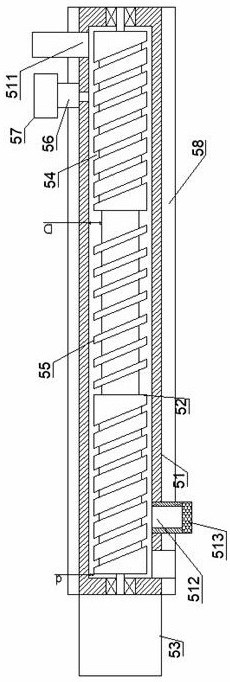

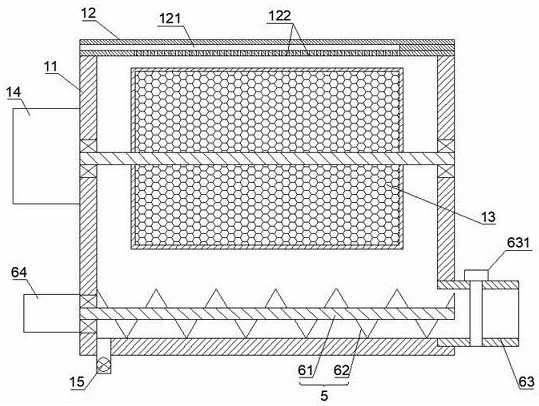

[0073] (1) Pretreatment of raw materials

[0074] Take 50 parts of rapeseed, 18 parts of sunflower seed, and 2 parts of linseed, first remove the sand and straw in the rapeseed, sunflower seed, and linseed respectively, and then press the rapeseed, sunflower seed, and linseed with their own oil pressing equipment The cleaning device 1 in the cleaning device adopts spray cleaning for dust, mold and other harmful substances on the surface, and the cleaning time does not exceed 30 minutes.

[0075] (2) Oil drying treatment

[0076] The oils cleaned in step (1) are transported to the drying device 2 for drying through the first oil conveying mechanism 6 of the respective oil pressing equipment, and the temperature of the drying hot air is kept at 30°C.

[0077] (3) Oil crushing treatment

[0078] The oils af...

Embodiment 2

[0095] The raw material of a flavored pressed vegetable oil comprises 60 parts of rapeseed, 20 parts of sunflower seed, 3 parts of linseed and 5 parts of orange peel.

[0096] (1) Pretreatment of raw materials

[0097] Take 60 parts of rapeseed, 20 parts of sunflower seed, and 3 parts of flaxseed, first remove the sand and straw in rapeseed, sunflower seed, and flaxseed respectively, and then press rapeseed, sunflower seed, and flaxseed respectively with their own oil pressing equipment The cleaning device 1 in the cleaning device adopts spray cleaning for dust, mold and other harmful substances on the surface, and the cleaning time does not exceed 30 minutes.

[0098] (2) Oil drying treatment

[0099] The oils cleaned in step (1) are transported to the drying device 2 for drying through the first oil conveying mechanism 6 of the respective oil pressing equipment, and the temperature of the drying hot air is kept at 30°C.

[0100] (3) Oil crushing treatment

[0101] The oil...

Embodiment 3

[0115] The raw material of a flavored pressed vegetable oil comprises 30 parts of peanuts, 20 parts of sunflower seeds, 2 parts of linseeds, 2 parts of perilla seeds and 5 parts of dry carrot powder.

[0116] (1) Pretreatment of raw materials

[0117]Take 30 parts of peanuts, 20 parts of sunflower seeds, 2 parts of flax seeds, and 2 parts of perilla seeds. The dust, mold and other harmful substances on the surface of the perilla seeds and perilla seeds are cleaned by spraying with the cleaning device 1 in their respective oil pressing equipment, and the cleaning time does not exceed 30 minutes.

[0118] (2) Oil drying treatment

[0119] The oils cleaned in step (1) are transported to the drying device 2 for drying through the first oil conveying mechanism 6 of the respective oil pressing equipment, and the temperature of the drying hot air is kept at 30°C.

[0120] (3) Oil crushing treatment

[0121] The oils after drying in step (2) are transported to the crushing device 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com