A production process of charcoal bed for fireplace with good simulation effect

A production process and carbon bed technology, which is applied in the field of carbon bed production technology for fireplaces, can solve problems such as poor flame realistic effect, and achieve the best simulation effect and good simulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

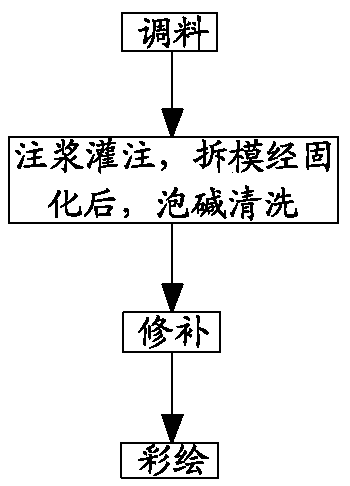

[0020] The present invention also provides a production process for a charcoal bed for a fireplace with good simulation effect, comprising the following steps:

[0021] ① Seasoning;

[0022] ② Grouting, demoulding and completion of the curing period after at least 48 hours, and then cleaning with sodium hydroxide; the purpose of sodium hydroxide is to remove grease, and the concentration of alkali is 15% mol / L;

[0023] ③ Repair;

[0024] ④Painting: Compared with the sample painting, the finished product is obtained after the light transmission test in the darkroom; specifically, it adopts the method of cross-checking the inspection and painting according to the sample, and the following three steps are included in the painting:

[0025] A: Use diluted black paint to spray the entire carbon bed for the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com