Nitrogen-filled packaging device and method for small-package powder

A nitrogen-filled packaging and small-packaging technology is applied in the field of small-package powder nitrogen-filled packaging devices, which can solve problems such as poor sealing performance and reduced product bagging capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

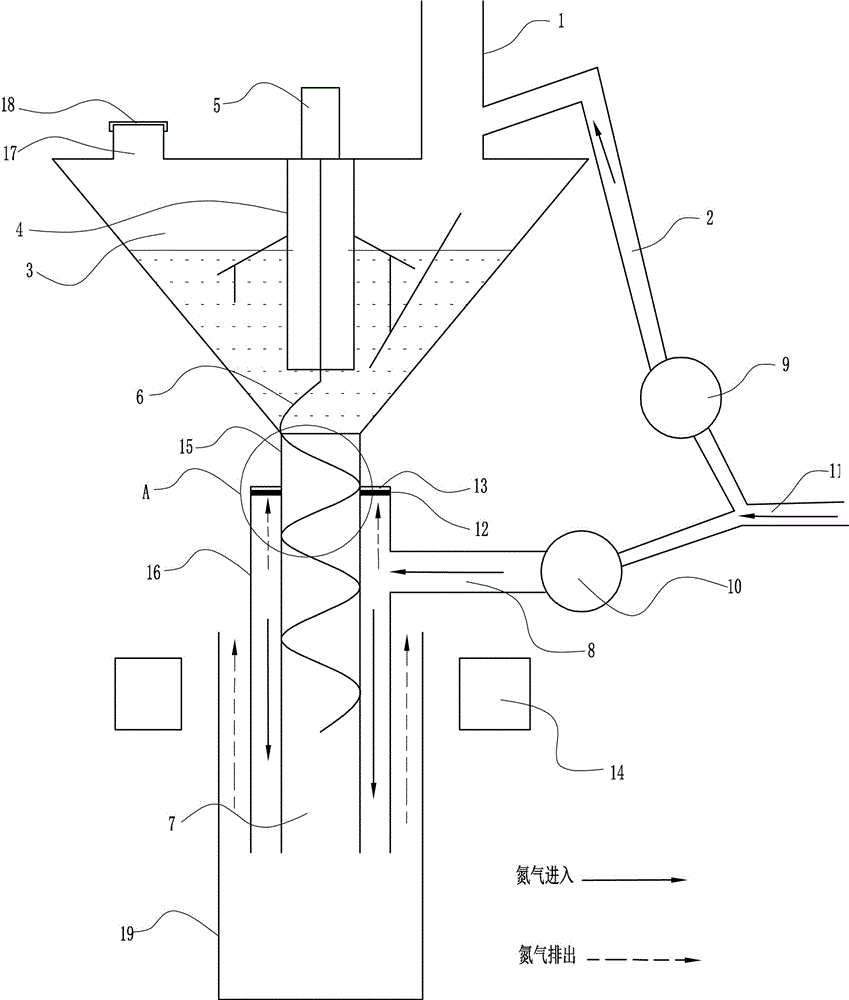

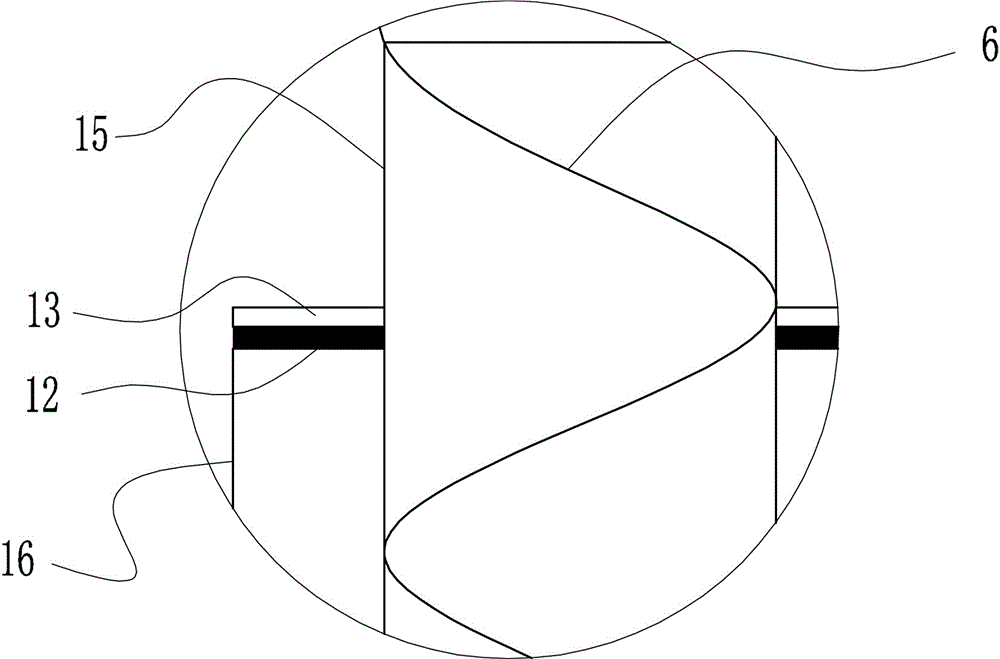

[0033] A nitrogen-filled packaging device for small-package powder, such as Figure 1-Figure 2 As shown, it includes feeding pipe 1, nitrogen pipe Ⅰ2, collecting hopper 3, agitator 4, motor 5, metering screw 6, filling pipe 7, nitrogen pipe Ⅱ8, flow meter Ⅰ9, flow meter Ⅱ10, nitrogen pipe Ⅲ11 and pull-down Edge banding device 14;

[0034] The feeding pipe 1 is connected to the nitrogen pipe I2, the nitrogen pipe I2 is connected to the flowmeter I9, the lower end of the feeding pipe 1 is connected to the collecting hopper 3, and the collecting hopper 3 is provided with an air outlet 17 and a motor 5, and the outlet is installed There are cloth bags 18;

[0035] The agitator 4 is installed in the collecting hopper 3, the upper end of the agitator 4 is connected with the motor 5, the lower end of the agitator 4 is connected with the metering screw 6, and the metering screw 6 extends into the filling pipe 7;

[0036] The filling pipe 7 is respectively connected with the collecti...

Embodiment 2

[0041] A nitrogen-filled packaging device for small-package powder, such as Figure 1-Figure 2As shown, it includes feeding pipe 1, nitrogen pipe Ⅰ2, collecting hopper 3, agitator 4, motor 5, metering screw 6, filling pipe 7, nitrogen pipe Ⅱ8, flow meter Ⅰ9, flow meter Ⅱ10, nitrogen pipe Ⅲ11 and pull-down Edge banding device 14;

[0042] The feeding pipe 1 is connected to the nitrogen pipe I2, the nitrogen pipe I2 is connected to the flowmeter I9, the lower end of the feeding pipe 1 is connected to the collecting hopper 3, and the collecting hopper 3 is provided with an air outlet 17 and a motor 5, and the outlet is installed There are cloth bags 18;

[0043] The agitator 4 is installed in the collecting hopper 3, the upper end of the agitator 4 is connected with the motor 5, the lower end of the agitator 4 is connected with the metering screw 6, and the metering screw 6 extends into the filling pipe 7;

[0044] The filling pipe 7 is respectively connected with the collectin...

Embodiment 3

[0049] A nitrogen-filled packaging device for small-package powder, such as Figure 1-Figure 2 As shown, it includes feeding pipe 1, nitrogen pipe Ⅰ2, collecting hopper 3, agitator 4, motor 5, metering screw 6, filling pipe 7, nitrogen pipe Ⅱ8, flow meter Ⅰ9, flow meter Ⅱ10, nitrogen pipe Ⅲ11 and pull-down Edge banding device 14;

[0050] The feeding pipe 1 is connected to the nitrogen pipe I2, the nitrogen pipe I2 is connected to the flowmeter I9, the lower end of the feeding pipe 1 is connected to the collecting hopper 3, and the collecting hopper 3 is provided with an air outlet 17 and a motor 5, and the outlet is installed There are cloth bags 18;

[0051] The agitator 4 is installed in the collecting hopper 3, the upper end of the agitator 4 is connected with the motor 5, the lower end of the agitator 4 is connected with the metering screw 6, and the metering screw 6 extends into the filling pipe 7;

[0052] The filling pipe 7 is respectively connected with the collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com